It’s a quiet morning in the workshop.

Your drill has been running perfectly for months — until suddenly, your app sends a notification: “Potential bearing wear detected. Service recommended within 10 hours of use.”

You didn’t hear a sound. You didn’t see a sign. But your tool knew.

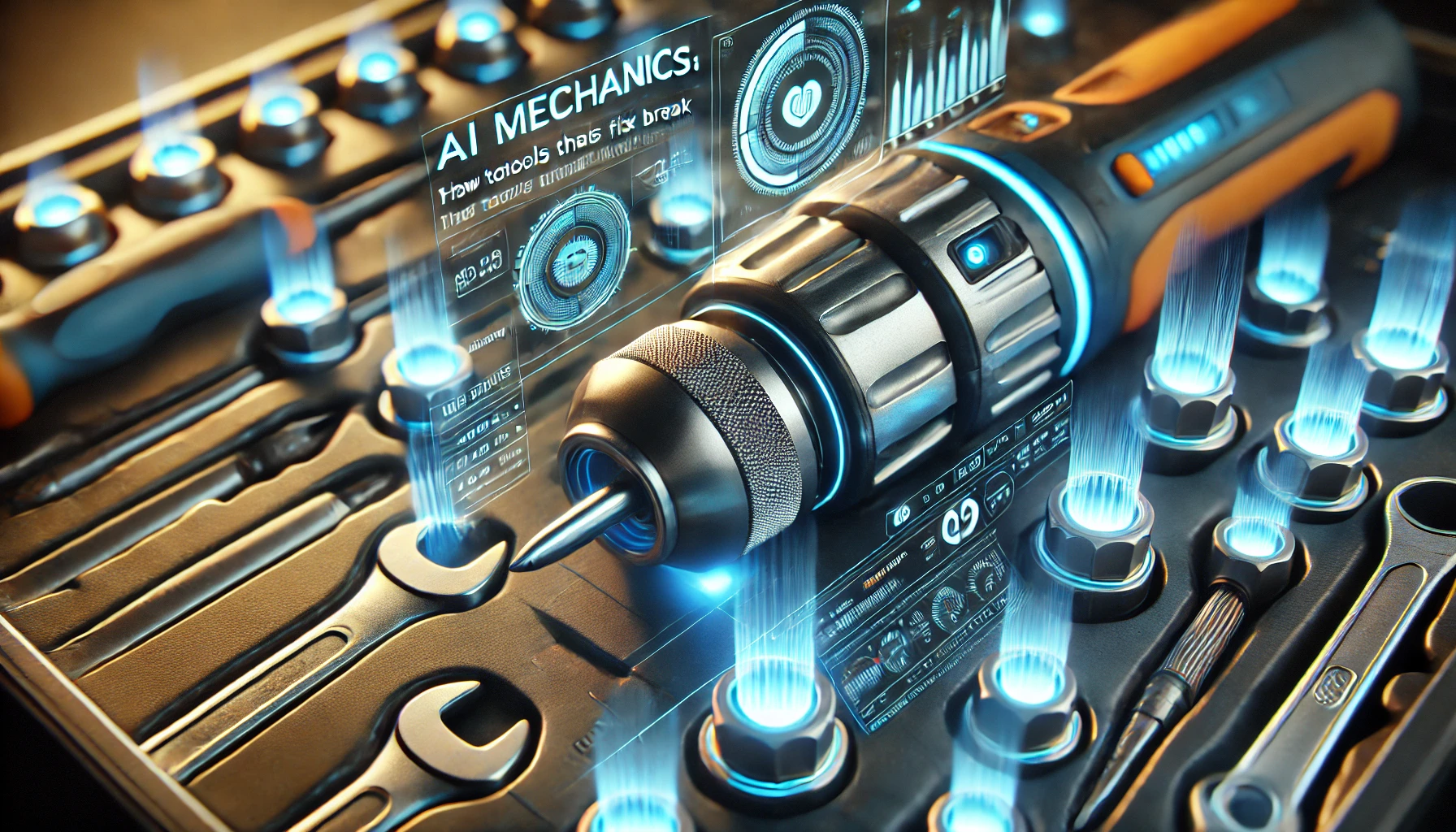

Welcome to the age of AI mechanics — where machines are no longer waiting to fail before they’re fixed. They’re learning to fix themselves.

At ToolCraftz, we’ve explored how AI and IoT are transforming workshops into intelligent ecosystems. But predictive maintenance — the ability for tools to detect and prevent failure — is perhaps the most game-changing evolution of all.

From Diagnostics to Prediction

Traditionally, maintenance has been reactive. You use a tool until something feels off — a vibration, a slowdown, a strange smell — and only then do you act.

But predictive AI changes the entire model.

By collecting and analyzing thousands of data points from sensors — torque pressure, heat, vibration, energy flow — tools can now identify subtle patterns that precede mechanical issues.

According to IEEE Spectrum, this “early warning” capability can reduce downtime by up to 40% in industrial settings — and that same intelligence is now entering handheld tools and workshop systems.

This shift builds on the foundation we explored in How AI Is Reinventing the Future of Tools and Workshops — where software no longer just operates tools, but teaches them to understand wear and efficiency.

The Mechanics Behind Machine Learning

At the heart of every AI mechanic is pattern recognition.

When a tool records consistent performance over time, AI models learn what “normal” looks like. Any deviation — even microscopic — is flagged instantly.

For instance:

- A sudden spike in current flow may indicate motor resistance.

- Changes in torque pattern can signal bearing degradation.

- Slight temperature rises might mean friction or misalignment.

This data is processed either onboard or in the cloud, where machine learning systems adapt to the user’s habits — creating a personalized performance model for every workshop.

It’s an extension of what we described in Inside the Smart Workshop: Connected Tools That Think for You — but now, instead of just communicating, the tools are interpreting.

AI Mechanics in Action

A few forward-thinking companies are already experimenting with this technology:

- Bosch Professional uses predictive software that tracks tool usage and temperature in real time.

- Makita is developing sensors for early fault detection in heavy-duty tools.

- Hilti has rolled out cloud-based monitoring for its connected tool lineup.

Each system relies on a similar principle: data-driven awareness.

As noted by the MIT Technology Review, even low-cost sensors can now detect mechanical irregularities invisible to the human ear or hand.

In the Workshop of the Future: How AI + IoT Will Automate Your Tool Bench, we saw how automation enhances productivity. Predictive maintenance takes that concept one step further — from assistance to foresight.

Repair, Reinvented

Here’s where AI mechanics connect beautifully with a cultural shift: the repair movement.

Instead of discarding failing tools, predictive analytics empower users to repair them early — before damage spreads.

In our feature Repair, Don’t Replace: The New Ethics of Modern Craftsmanship, we discussed how sustainability and technology can work hand in hand.

AI-driven diagnostics are the missing link — helping makers preserve performance while reducing waste.

It’s a subtle but powerful evolution: your tools don’t just serve you; they communicate with you.

The Future: Fully Self-Healing Systems

By 2030, predictive maintenance will merge with self-healing design — where certain materials or electronic components can restore themselves.

Imagine coatings that repair microfractures, batteries that reroute energy around damaged cells, or AI firmware that recalibrates sensors automatically.

This future isn’t far-fetched. Researchers at University of Cambridge and Oak Ridge National Laboratory are already experimenting with adaptive materials and autonomous monitoring systems.

In the same way tabless battery technology revolutionized energy efficiency, these AI mechanics could redefine durability itself.

Craftsmanship + Intelligence = Longevity

At its core, predictive maintenance isn’t just about keeping tools running — it’s about giving craftsmanship more time to breathe.

When you eliminate breakdowns, you create space for precision, focus, and creativity.

AI mechanics represent the future harmony of craft and code: tools that know themselves, systems that serve sustainably, and makers who never lose momentum.

And as always, ToolCraftz will be here — documenting every spark in the evolution of smarter craftsmanship.