Under the bright lights of the Miss USA stage, all eyes are drawn to one thing before the winner even speaks — the crown. It sparkles under the spotlight, a delicate piece of art that looks effortless but hides hours of work, precision, and craft. Behind its shimmer is a world of designers, metalworkers, and jewelers who bring together artistry, engineering, and tool mastery to create a symbol of excellence.

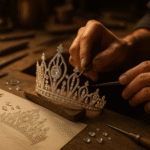

Each year, crown designers begin months in advance, sketching new concepts inspired by themes of empowerment and tradition. What begins as a pencil drawing soon becomes a detailed blueprint marked with precise measurements and gem placements. The process then moves to the workshop, where expert artisans shape the base using precision hand tools, jeweler’s saws, micro files, and burnishers — the same kind of fine instruments used in high-end watchmaking. Unlike mass production, every curve and cut on the crown is done by hand, demanding the same patience and accuracy a craftsman brings to any intricate metal project.

Crafting the frame often starts with sterling silver or platinum alloys, chosen for both strength and malleability. To ensure symmetry, metals are shaped over casting molds and refined using rotary polishers and ultrasonic engravers. The skill lies in knowing exactly how much pressure to apply — too little and the piece won’t form; too much and it fractures. This precision parallels the work seen in modern workshops, where control tools and balance determine the quality of every finished product. Articles such as Top 10 Must-Have Tools for Every Modern Workshop in 2025 highlight how even in large-scale builds, craftsmanship relies on the right touch and the right tool.

Once the frame is finished, jewelers begin the most meticulous step — setting stones. Using prong setters, tweezers, and optical magnifiers, artisans mount hundreds of crystals and gems by hand, sometimes spending up to forty hours aligning every facet for even light reflection. The precision required here mirrors the kind of calibration techniques discussed in How to Maintain and Sharpen Your Power Drill Bits Like a Pro, where consistency and control define excellence. Each gem must catch light from every angle — just as each tool in a workshop must perform under every condition.

Technology has quietly elevated this ancient art. Some designers now rely on 3D modeling software and CNC engraving machines to prototype crown shapes before production. Digital blueprints help visualize balance and weight distribution, preventing imperfections that might otherwise appear once gems are added. This blend of human skill and technological precision reflects the same evolution happening in toolmaking itself — where craftsmanship and innovation converge. You can see this balance of tradition and tech in How Smart Tools and IoT Are Transforming the Future of DIY, which explores how modern tools enhance accuracy without replacing the craftsman’s instinct.

Sustainability has also entered the conversation. Many jewelers now choose lab-grown stones or recycled metals to reduce environmental impact without compromising brilliance. This approach parallels a larger shift across industries, as seen in How Inflation and Policy Shifts Are Reshaping the Tool Industry in 2025, where efficiency and resource awareness drive design choices. In both worlds — luxury jewelry and industrial craftsmanship — sustainability has become a mark of professionalism, not compromise.

By the time the tiara reaches the stage, it’s more than just decoration. It represents hundreds of design hours, the precise hum of tools, and the quiet focus of makers who rarely receive the spotlight. Each crown embodies the same principles that guide every craftsman: patience, precision, and pride in the smallest details. For the builders and artisans behind it, the true beauty of the crown isn’t in how it shines — it’s in how perfectly it’s made.