The world of precision cutting! If you’ve ever wondered about the versatile tool that goes by the name of a “chop saw,” you’re in the right place. In this exploration, we’ll unveil the secrets behind what does a chop saw do, shedding light on its multifaceted functions and why it’s a must-have for DIY enthusiasts and professionals alike.

Whether you’re a seasoned carpenter or just starting your DIY journey, understanding what a chop saw can accomplish is critical to unlocking a world of efficient, accurate, and effortless cuts. So, without further ado, let’s dive into the heart of the matter and uncover the wonders of this indispensable tool.

Types of Chop Saws: Your Comprehensive Guide

In the world of woodworking and metalworking, precision and efficiency are paramount. To achieve the finest cuts with ease and accuracy, the right tools are essential.

Among these tools, chop saws play a pivotal role.Whether you’re a seasoned craftsman or just starting your DIY journey, understanding these chop saw variations will help you make an informed choice for your projects.

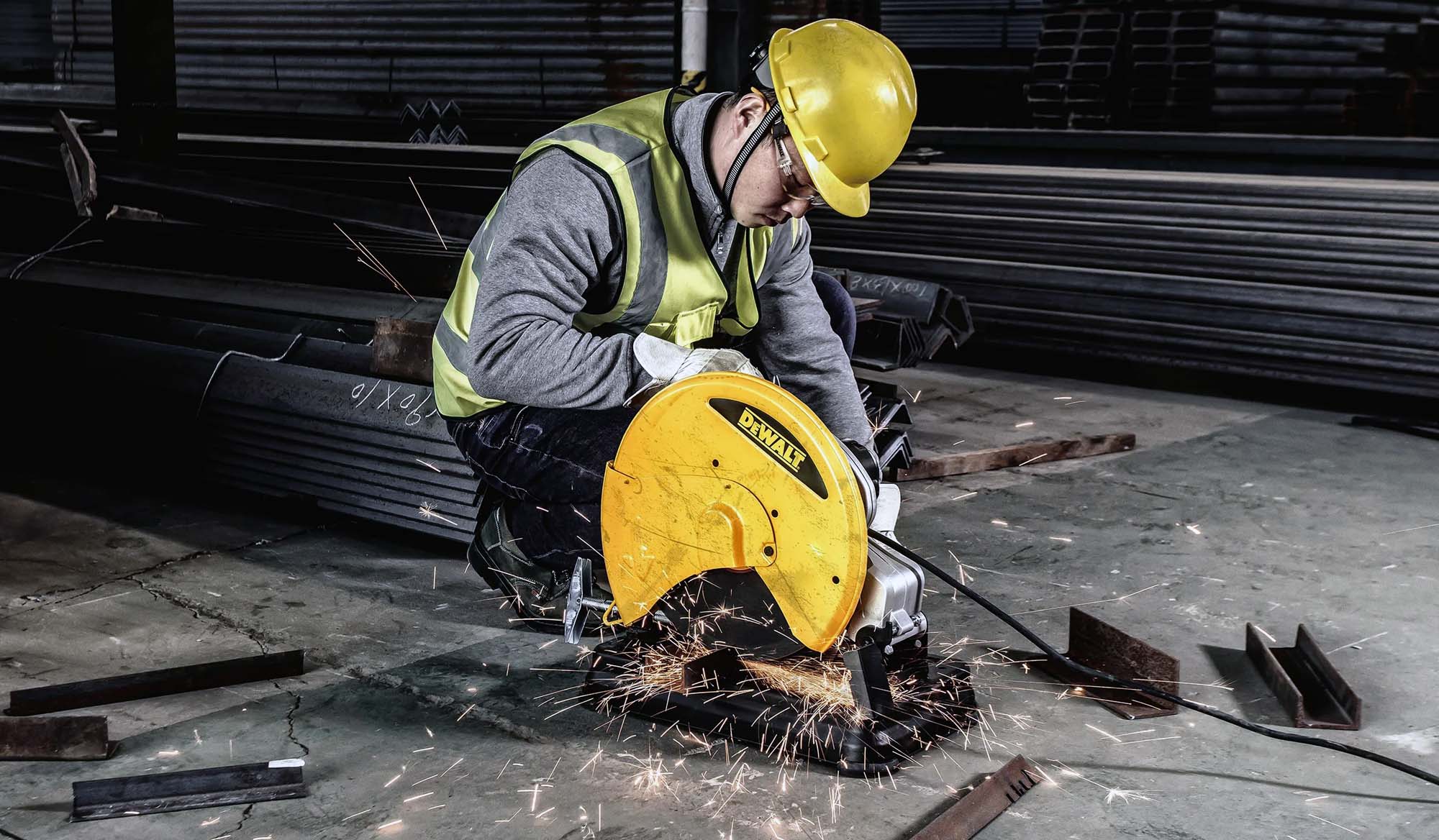

Abrasive Chop Saws

Abrasive chop saws, also known as abrasive disc cut-off saws, are workhorse tools in metalworking. They owe their name to the abrasive discs they use for cutting. These discs are similar to grinding wheels and are designed to slice through metal with ease.

Features

- Abrasive Discs: The hallmark of these saws is their abrasive cutting discs. These discs come in various sizes, with larger ones offering deeper cuts.

- Durable Construction: Abrasive chop saws are built to withstand the rigors of metal cutting, making them durable and long-lasting.

- Adjustable Angles: Some models allow you to adjust the cutting angle, providing versatility for various applications.

Applications

Abrasive chop saws are predominantly used in metal fabrication and construction industries. They excel at cutting through steel, iron, and other metals quickly and cleanly. Welders and metalworkers often rely on these saws for precise cuts in their projects.

Cold Saw

A cold saw is a specialized cutting tool designed for clean, burr-free cuts in metal. Unlike abrasive chop saws, cold saws utilize a circular blade with teeth specially designed for metal cutting.

Features

- Circular Blade: Cold saws employ a high-speed, circular blade with carbide or high-speed steel teeth. This blade design ensures precise and clean cuts.

- Coolant System: These saws incorporate a coolant system to prevent overheating, ensuring the material remains cool during the cutting process.

- Low Noise: Cold saws are known for their relatively quiet operation compared to abrasive chop saws.

Applications

Cold saws are the top choice for tasks that demand smooth, accurate cuts without additional finishing. They are widely used in manufacturing, automotive, and aerospace industries.

Compound Miter Saw

Moving away from metal cutting, let’s explore the world of woodworking with the compound miter saw.

Features

- Miter and Bevel Cuts: Compound miter saws excel at making miter (angled) and bevel (tilted) cuts, making them ideal for molding, framing, and trim work.

- Precision: These saws are renowned for their precision, allowing woodworkers to create intricate designs with ease.

Applications

Woodworkers, carpenters, and DIY enthusiasts often turn to compound miter saws for tasks that require angled or beveled cuts, such as crown molding installation or crafting custom furniture.

Sliding Compound Miter Saw

Taking the versatility of the compound miter saw a step further; we have the sliding compound miter saw.

Features

- Sliding Action: These saws have a sliding arm that extends the blade’s reach, allowing for broader cuts.

- Compound Capabilities: Like their non-sliding counterparts, they can make miter and bevel cuts, but with the added benefit of increased cutting capacity.

- Fine Adjustments: Sliding compound miter saws offer fine adjustment options for precise results.

Applications

For woodworking projects that involve more significant pieces of lumber or broader boards, the sliding compound miter saw is the tool of choice. It provides the flexibility needed to tackle a broad range of projects efficiently.

Accuracy and Precision: The Ultimate Guide to Using a Chop Saw for Perfect Cuts

Precision Techniques

A. Measuring and Marking: Precision starts with precise measurements and markings. We’ll explore techniques for measuring and marking your workpiece to ensure that your cuts are spot-on every time.

B. Fence and Stops: The chop saw’s fence and adjustable stops are your allies in achieving consistent, repeatable cuts. We’ll show you how to utilize these features effectively.

- Common Challenges and Solutions:

- Even the most skilled artisans encounter challenges. We’ll address common issues affecting accuracy and precision, such as blade deflection material movement, and how to troubleshoot them effectively.

- Advanced Techniques:

- For those looking to take their craftsmanship to the next level, we’ll explore advanced techniques like compound miter cuts, bevel cuts, and complex angles with precision.

- Maintenance and Care:

- To maintain the accuracy and longevity of your chop saw, regular maintenance is essential. We’ll provide a step-by-step guide on how to clean, lubricate, and replace parts when needed.

Wear Appropriate Personal Protective Equipment (PPE)

The first rule of using a chop saw is to dress for safety. Proper PPE can significantly reduce the risk of injuries. Here’s what you should wear:

Secure the Workpiece

Ensuring that your workpiece is stable and secure is vital for precise and safe cutting. Use clamps or a vise to hold the material firmly in place. Avoid hand-holding the workpiece, as it can lead to accidents.

Maintain a Clean Workspace

Keep your work area clutter-free to prevent tripping hazards and make it easier to focus on the task at hand. Swep away debris regularly to maintain a clean, safe environment.

Check the Saw

Before every use, inspect the chop saw for any damage, loose parts, or worn-out components. Ensure the blade is sharp, properly aligned, and securely attached. Replace any damaged or dull blades immediately.

Position Yourself Correctly

Stand to the side of the chop saw, never directly in line with the blade. Maintain a stable stance and keep your body out of the potential kickback zone.

Mind the Cut Line

Permanently mark a clear-cut line on your workpiece and position it so the blade will cut through the waste material, not the part you intend to keep.

Start Slowly

Take your time cutting. Start the chop saw at a lower speed and gradually increase it as needed. This prevents the saw from binding or kicking back.

Keep Both Hands on the Handle

Maintain a firm grip on the saw’s handle with both hands throughout the cut. Avoid any distractions while cutting and maintin complete control.

Let the Blade Stop

After completing a cut, please wait for the blade to come to a complete stop before lifting it from the workpiece or moving the material.

Disconnect Power When Not in Use

Unplug or turn off the chop saw when not used, especially if you have children or inexperienced individuals in your workspace.

Choosing the Right Blade for Your Chop Saw: A Comprehensive Guide

Wood Cutting Blades

Wood is one of the most commonly cut materials using a chop saw. Whether building furniture, framing a house, or working on a DIY project, having the right wood-cutting blade is essential. Here are some key considerations:

a. Tooth Count: Wood cutting blades typically come in two main varieties: crosscut and rip blades. Crosscut blades have more teeth (usually between 40 and 80) and are designed for smooth, clean cuts across the grain. Rip blades have fewer teeth (usually 10 to 30) and are ideal for cutting along the grain.

b. Blade Material: Carbide-tipped blades are the preferred choice for cutting wood. They stay sharp longer and can withstand the abrasive nature of wood fibers.

c. Blade Diameter: Ensure the blade’s diameter matches your chop saw’s specifications. Standard sizes include 10 inches and 12 inches.

Metal Cutting Blades

If your project involves cutting metal, you’ll need a specialized blade to do the job efficiently and safely. Here are some considerations for metal cutting blades:

a. Blade Type: There are two main types of metal cutting blades – abrasive discs and cold cut blades. Abrasive discs are suitable for cutting thin metals, while cold-cut blades are designed for thicker materials. Cold-cut blades produce less heat, reducing the risk of warping the metal.

b. Tooth Count: Metal cutting blades have fewer teeth than wood blades, typically around 30 to 60 teeth per blade.

c. Blade Material: Blades for cutting metal are typically made from high-speed steel (HSS) or carbide. Carbide-tipped blades are more durable and maintain their sharpness longer.

Specialty Blades

For projects involving materials other than wood and metal, you may need specialty blades. Here are a few examples:

a. Masonry Blades: Designed for cutting concrete, brick, and stone. These blades have abrasive particles embedded in them to handle rigid materials.

b. Diamond Blades: Ideal for cutting through ceramic tiles, porcelain, and glass. Diamond blades are exact and produce clean cuts.

c. Composite Blades: If you’re working with composite materials like fiberglass or carbon fiber, specialized composite blades are essential to prevent splintering and delamination.

A Comprehensive Guide to Chop Saw Maintenance and Care for Longevity”

Safety First:

Before diving into the maintenance and cleaning procedures, always prioritize safety. Ensure the chop saw is disconnected from the power source, the blade is locked in place, and you’re wearing appropriate safety gear, including safety glasses and hearing protection.

Cleaning:

Regular cleaning helps prevent dust and debris buildup, which can affect your chop saw’s performance. Here’s how to do it:

a. Dust Collection System: Empty or replace the dust collection bag or container regularly to maintain efficient dust collection. Ensure that all dust ports and hoses are clear of debris.

b. Blade Cleaning: Remove the blade guard and clean the blade with a blade cleaning solution or soapy water. Scrub gently with a nylon brush to remove pitch and resin buildup. Rinse and dry thoroughly before reinstalling.

c. Motor Housing: Use compressed air or a small brush to clean the motor housing, vents, and cooling fans. Ensure proper ventilation to prevent overheating.

d. Table and Base: Lubricate moving parts and pivot points with a light machine oil.

Blade Maintenance

A sharp blade is crucial for precise and efficient cuts. Follow these steps to maintain your chop saw blade:

a. Regular Sharpening: Sharpen the blade as needed or when you notice decreased cutting performance. Use a blade sharpening tool or take it to a professional sharpening service.

b. Alignment: Check the blade for proper alignment with the miter slot and the fence. Adjust if necessary to ensure accurate cuts.

- Check Electrical Components: Inspect the power cord, switches,

- Lubrication: Apply lubricant to moving parts and pivot points regularly to prevent friction and ensure smooth operation. Refer to your chop saw’s user manual for specific lubrication points.

- Blade Guard and Safety Features: Ensure that the blade guard and all safety features are working correctly. Replace any damaged or malfunctioning parts promptly to maintain a safe working environment.

- Store Properly: When not in use, store your chop saw in a dry and protected area. Use a cover to prevent dust and moisture from accumulating on the saw.

Choosing the Right Chop Saw: A Comprehensive Guide

Determine Your Needs

Before diving into the world of chop saws, it’s crucial to define your specific needs. Consider the following:

- Material: What type of materials will you be cutting? Standard options include wood, metal, plastic, and more. Different chop saws are designed for different materials.

- Frequency of Use: Are you a professional contractor who will use the saw daily, or are you a hobbyist who will use it occasionally? Your usage frequency will impact the saw’s durability requirements.

- Size of Materials: Consider the dimensions of the materials you’ll be cutting. Some chop saws are better suited for larger pieces, while others are more compact and ideal for minor cuts.

Blade Size and Type

The size and type of blade you choose are crucial factors. Blade sizes typically range from 8 to 16 inches

Additionally, consider the type of blade you need:

- Tooth Count: Blades with more teeth provide cleaner cuts in wood, while those with fewer teeth are better for metal and other rigid materials.

- Material Compatibility: Make sure the blade is designed for the specific material you plan to cut. There are blades for wood, metal, masonry, and more.

Power Source

Chop saws are available in two primary power sources: corded and cordless (battery-powered). The choice between the two depends on your portability needs and access to power outlets. Corded saws generally provide more power and consistent performance but may limit your mobility. Cordless saws offer flexibility but may require frequent battery recharging.

Motor Power and Speed

The motor power of a chop saw is measured in horsepower (HP) or amps. Higher power typically equates to more cutting capability. Consider the motor power with the materials you’ll be cutting. Additionally, pay attention to the saw’s RPM (revolutions per minute). A higher RPM is beneficial for smoother cuts.

- Guarding System: Ensure the saw has a robust guarding system that covers the blade during operation.

- Safety Switch: Look for a saw with a safety switch to prevent accidental starts.

- Stability: Choose a chop saw with a stable base and anti-slip features to prevent accidents.

- Dust Collection: Some saws have built-in dust collection systems to clean your workspace and reduce health risks.

Brand Reputation and Reviews

Research the reputation of the brands you’re considering. Established brands with a history of quality products are often a safer bet. Additionally, read customer reviews to gather insights from real users about their experiences with specific models.

Budget

Finally, set a realistic budget for your chop saw. While it’s tempting to go for the most expensive model, it may be optional. Determine a budget that balances quality and affordability.

Conclusion

A chop saw is versatile and essential in woodworking, construction, and metalworkingIts ability to create angled and straight cuts makes it a valuable addition to any workshop, allowing artisans to achieve the desired results in their endeavors. So, in craftsmanship and construction, a chop saw plays a pivotal role in turning raw materials into finely crafted creations.