If you’re a woodworking enthusiast or a professional carpenter who owns a Bosch miter saw, you’ve probably heard about the essential accessory known as the “Bosch miter saw zero clearance insert.” This small but crucial component can significantly affect the precision and safety of your woodworking projects.

This guide will delve into the Bosch miter saw zero clearance insert, explaining what it is, why it matters, and how it can enhance your cutting accuracy and overall woodworking experience.

Understanding Zero Clearance Inserts

Zero clearance inserts are essential for table saws and other woodworking power tools. These inserts are crucial in enhancing safety and precision during cutting operations. Here’s a comprehensive understanding of zero-clearance inserts:

Purpose and Function

Zero clearance inserts are thin, flat plates or inserts that fit into the throat plate or opening surrounding the saw blade on a table saw or other saws with similar features. Their primary purpose is to close the gap or clearance between the blade and the insert.

Reduced Tearout and Chipout

By closing the gap around the blade, zero clearance inserts help minimize tear out and chip out on the underside of the workpiece. This is especially crucial when cutting materials like plywood or veneer, resulting in cleaner, smoother cuts.

Improved Safety

Zero-clearance inserts provide additional safety by reducing the risk of smaller workpieces falling into the gap around the blade. This prevents workpieces from becoming trapped or causing kickback during cutting operations.

Customizable Slots

Many zero-clearance inserts come with a precut slot that matches the saw blade’s width. However, the user can customize these slots to fit different blade widths and angles, offering versatility for various cutting tasks.

Materials and Compatibility

Zero-clearance inserts are typically made from phenolic resin, plastic, or wood. The choice of material depends on the user’s preference and the saw being used. Ensure compatibility with your specific saw model when selecting an insert.

Installation and Adjustment

Installing a zero clearance insert is relatively straightforward. It involves removing the standard throat plate and replacing it with the zero clearance insert. Users can often make fine adjustments to align the insert perfectly with the blade for optimal performance.

Aftermarket Inserts

While many table saws come with default throat plates, users often opt for aftermarket zero-clearance inserts tailored to their needs. These inserts may have features like leveling screws or replaceable inserts, making them a valuable addition to the workshop.

Maintenance

Zero clearance inserts can wear out over the long run because of the contact and intensity produced during cutting. Users should regularly inspect and replace inserts as needed to maintain their effectiveness.

In summary, zero-clearance inserts are indispensable accessories for woodworkers and artisans using table saws or similar tools.

They improve the quality of cuts by reducing tear-out and chipout, enhance safety by closing the gap around the blade, and offer versatility through customizable slots. Choosing the right zero clearance insert and maintaining it properly can significantly enhance the precision and safety of woodworking operations.

Why Bosch Miter Saw?

Choosing a Bosch miter saw can be an excellent decision for various reasons, as Bosch is a reputable brand known for its quality and innovation in power tools. Here’s why you might opt for a Bosch miter saw:

Precision and Accuracy: Bosch miter saws are renowned for their precision and accuracy in cutting. Many models come outfitted with laser guides or Drove work lights, assisting users in achieving precise and clean cuts in their woodworking and construction projects.

Dust Management: Bosch strongly emphasizes dust collection systems in their miter saws. Effective dust management keeps the work area clean, enhances visibility, and contributes to a healthier and safer working environment.

Variety of Models: Bosch offers many miter saw models, including compound, sliding compound, and compact miter saws. This variety allows users to choose a model that best suits their needs and budget.

Durability: Bosch miter saws are built to withstand the demands of job sites and workshops. They are known for their durable construction, ensuring long-lasting performance.

Ergonomics: Bosch designs its miter saws with user comfort and safety in mind. Features like ergonomic handles, intuitive controls, and comfortable grips contribute to a pleasant and safe working experience.

Portability: Many Bosch miter saws are designed for portability, making them suitable for on-site work. They often come with carrying handles or are compatible with Bosch’s portable miter saw stands.

Brand Reputation: Bosch has a strong reputation for producing high-quality power tools focusing on innovation and user satisfaction. Choosing a trusted brand can provide confidence in your tool investment.

Accessories and Attachments: Bosch offers a range of accessories and attachments, such as specialized blades, workpiece supports, and stands, to enhance the functionality and versatility of their miter saws.

Warranty and Customer Support: Bosch typically backs its miter saws with warranties and provides reliable customer support. This offers peace of mind in case of any issues with the tool.

Innovation: Bosch continually innovates in the power tool industry, introducing new features and technologies to improve the performance and usability of their miter saws.

Bosch miter saw is an attractive choice for woodworkers, contractors, and DIY enthusiasts looking for precision, durability, and user-friendly features. Whether you need a basic compound miter saw or a high-capacity sliding compound miter saw, Bosch offers an exhaustive scope of choices to meet your specific cutting needs. When you choose a Bosch miter saw, you’re investing in a tool backed by a legacy of quality and innovation in power tools.

Types of Zero Clearance Inserts

Zero clearance inserts are available in several types, each designed to cater to specific woodworking tools and tasks. These inserts serve the common purpose of reducing tear-out chips and enhancing safety during cutting operations. Here are the primary types of zero-clearance inserts:

Table Saw Zero Clearance Inserts

These inserts are designed specifically for table saws and are used to close the gap around the saw blade. They come in various sizes and can be customized for different blade widths and angles. Table saw zero clearance inserts are crucial for achieving clean, precise cuts, especially in materials prone to tear out.

Miter Saw Zero Clearance Inserts

Miter saws, including compound and sliding compound miter saws, can benefit from zero clearance inserts. These inserts are placed around the blade to minimize tear-out and support delicate workpieces, such as moldings and trim.

Router Table Zero Clearance Inserts

Router tables use zero clearance inserts to create a snug fit around the router bit. This reduces tear-out and prevents small workpieces from falling into the router table opening during routing operations.

Band Saw Zero Clearance Inserts

Band saws have openings around their blades, leading to tear-out and unsafe cutting conditions. Zero clearance inserts for band saws close these gaps, resulting in cleaner cuts and improved safety.

Circular Saw Zero Clearance Inserts

Circular saws can benefit from zero-clearance inserts that fit around the blade. These inserts help minimize tear-out on the bottom side of the workpiece and enhance cutting precision.

Scroll Saw Zero Clearance Inserts

Scroll saws use zero clearance inserts to reduce tear-out and improve accuracy when making intricate cuts, especially in thin or delicate materials.

Jigsaw Zero Clearance Inserts

Jigsaws can employ zero clearance inserts to minimize splintering and provide additional support for the workpiece, particularly during curved cuts and intricate designs.

Custom-Made Zero Clearance Inserts

Woodworkers often craft custom zero-clearance inserts to fit their specific tools and cutting requirements. These inserts can be made from materials like plywood, MDF, or plastic and are tailored to the user’s needs.

It’s important to note that zero clearance inserts, regardless of the type, can often be customized by the user to match the specific blade width and angle used in various woodworking projects.

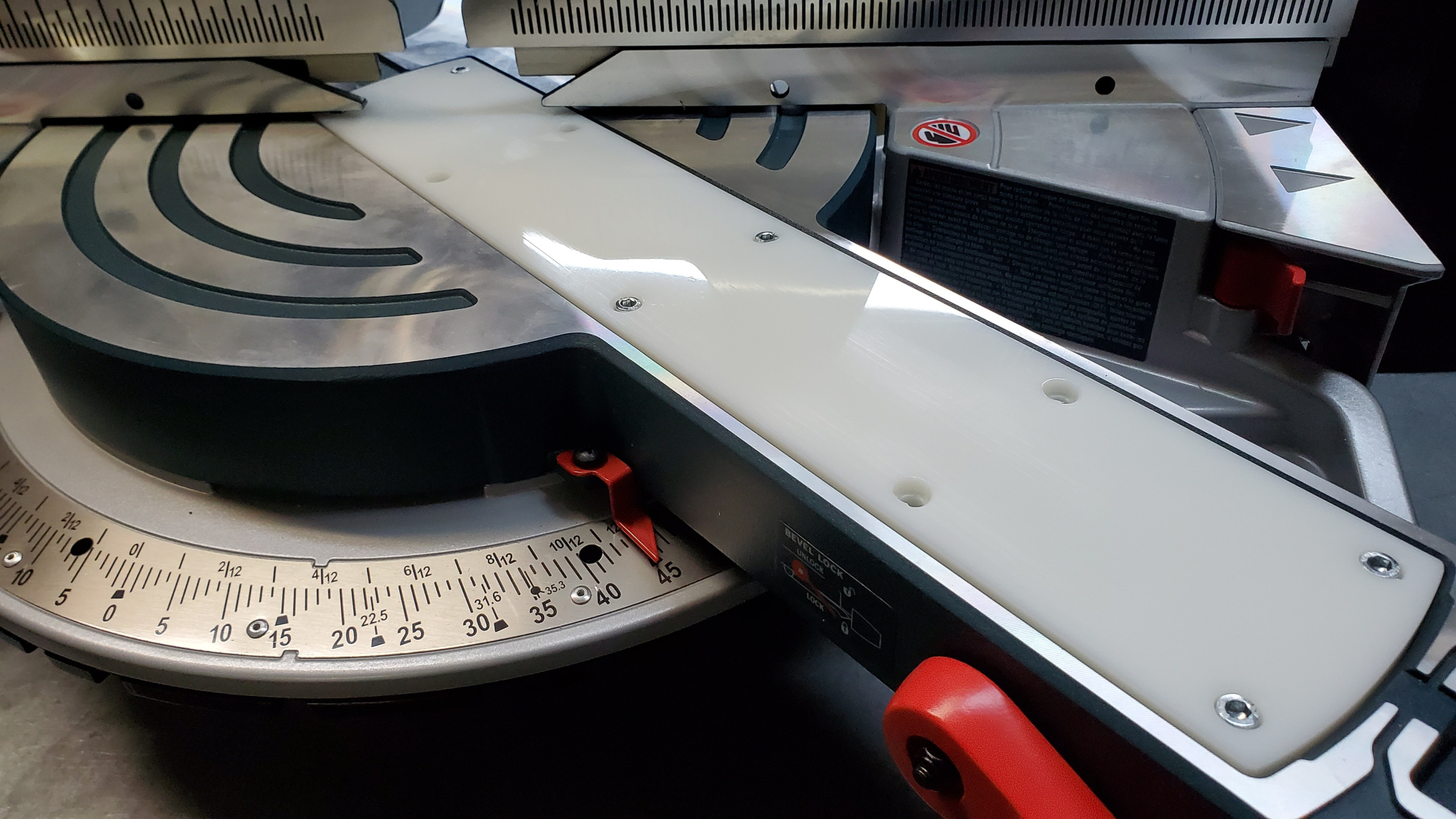

Installation of Bosch Miter Saw Zero Clearance Insert

Installing a zero clearance insert on a Bosch miter saw is a straightforward process that requires some essential tools and careful attention. Here’s a step-by-step guide to help you install a zero clearance insert on your Bosch miter saw:

Tools and Materials Needed

- Bosch miter saw

- Zero clearance insert (ensure it’s compatible with your Bosch miter saw model)

- Screwdriver or Allen wrench (if needed)

- Safety glasses and hearing protection (for safety)

Installation Steps

Safety First: Before you begin, ensure the miter saw is powered off and unplugged to prevent accidental starts. Also, wear appropriate safety gear, including safety glasses and hearing protection.

Remove the Standard Throat Plate: Locate the existing throat plate or insert it into your Bosch miter saw. It’s usually the standard plate that comes with the saw. Depending on your saw model, you may need a screwdriver or an Allen wrench to eliminate any screws or locking mechanisms that secure the plate.

Carefully unscrew or release these to take out the old throat plate.

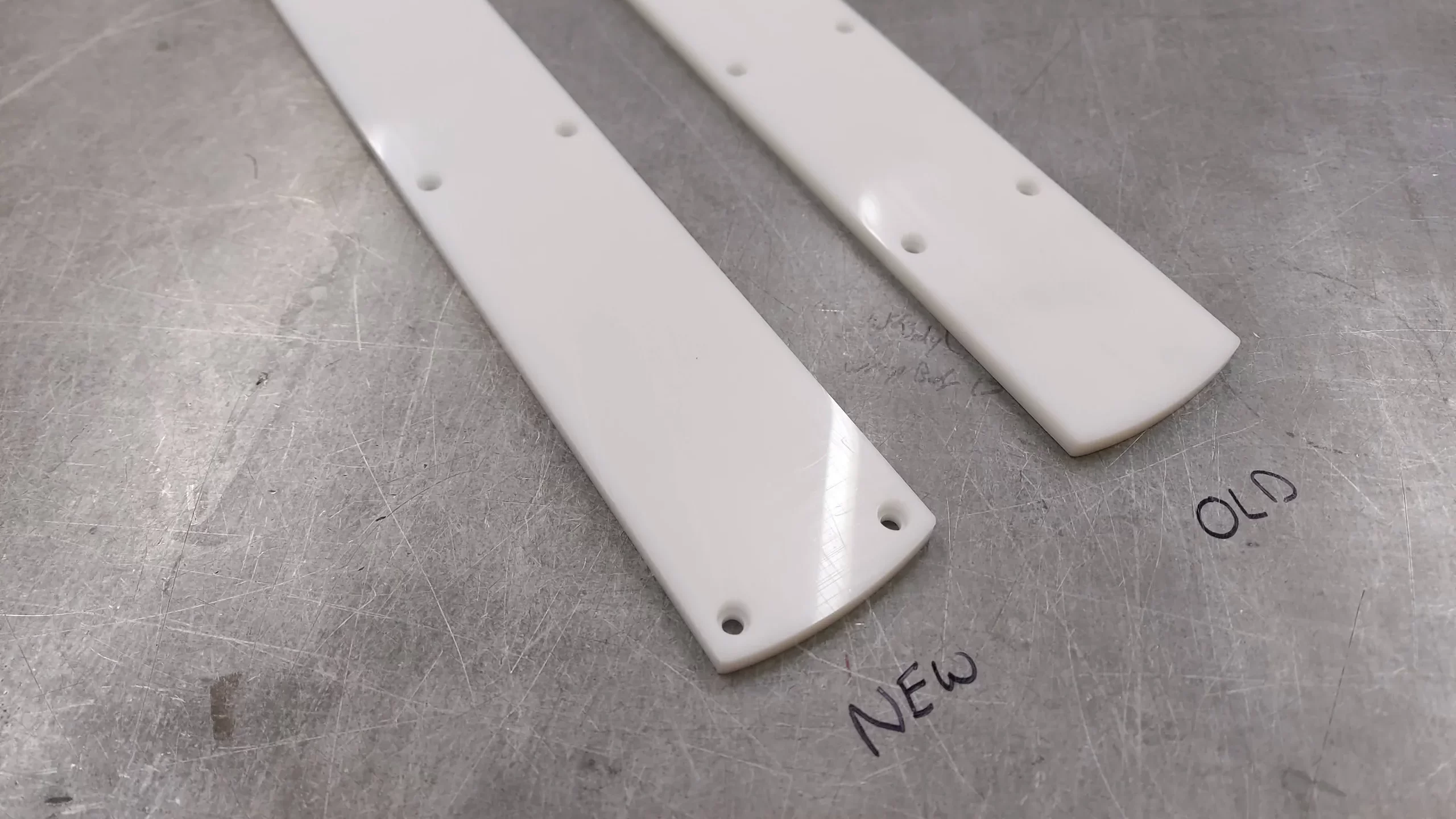

Prepare the Zero Clearance Insert: Take the zero clearance insert you intend to install. Ensure it’s the correct size and design for your Bosch miter saw model. Some inserts may precut, while others may require customization. Use a utility knife, jigsaw, or other appropriate tools to trim the insert to match the blade’s width and angle.

Insert the Zero Clearance Insert: Carefully place the zero clearance insert into the opening where the standard throat plate used to be. Ensure it sits flush with the table surface and covers the area around the saw blade completely.

Adjust the Fit (if necessary): Some zero clearance inserts may come with leveling screws or mechanisms to fine-tune the Fit. If your insert allows adjustments, use these features to make sure the insert sits perfectly level with the table surface and tightly surrounds the blade.

Secure the Insert: If your Bosch miter saw model requires it, use the provided screws or locking mechanisms to secure the zero clearance insert in place. Ensure it’s securely fastened to prevent it from moving during use.

Check for Proper Fit: Double-check that the zero clearance insert fits snugly around the saw blade and closes the gap effectively. It should leave minimal clearance between the blade and the insert, reducing the risk of tear out and improving cut quality.

Test the Miter Saw: Plug in it and power it on. Run some test cuts on scrap wood to ensure that the zero clearance insert is correctly installed and that it enhances cut quality by reducing tearout.

By following these means, you can introduce a zero clearance insert on your Bosch miter saw without much of a stretch, improving the precision and quality of your woodworking cuts while minimizing tear-out and chip-out. Always prioritize safety and take your time during the installation process.

Maintaining and Replacing Zero Clearance Inserts

Maintaining and replacing zero clearance inserts is a vital aspect of woodworking tool upkeep, ensuring the effectiveness and safety of tools like tables and miter saws. Routine maintenance involves:

- Occasional reviews for indications of wear or harm.

- Maintaining cleanliness to prevent sawdust buildup.

- Making any necessary adjustments to leveling mechanisms.

Many woodworking enthusiasts keep replacement inserts on hand for quick swaps when needed. When it comes time to replace an insert, safety is paramount. Tools should be turned off and unplugged to avoid accidental starts, and appropriate safety gear should be worn.

The existing standard insert is removed, and if the replacement isn’t precut or customizable, it’s trimmed to match the blade’s width and angle. The replacement insert is then carefully fitted into the opening, adjusted for a snug and level fit, and securely fastened if required. Testing the tool with the new insert ensures it functions correctly, maintaining the quality of woodworking projects.

Tips for Optimal Performance of Zero Clearance Inserts

To guarantee the ideal presentation and life span of zero clearance inserts in your woodworking tools, including table saws, miter saws, and routers, consider the following tips:

Proper Installation: Ensure you install zero clearance inserts correctly, following the manufacturer’s instructions. The insert should sit flush with the table surface and cover the area around the blade or bit utterly.

Regular Inspection: Periodically inspect your zero clearance inserts for wear, damage, or signs of deterioration. Replace them as needed to maintain their effectiveness.

Use for Specific Tasks: Dedicate zero clearance inserts to specific tasks or blade/bit types. For example, have one insert for crosscuts, one for ripping, and another for dado cuts. This minimizes the need for constant adjustments.

Support for Thin Materials: When cutting thin materials, use a sacrificial backer board or auxiliary fence to provide additional support and prevent tear-out.

Maintain Cleanliness: Keep your zero clearance inserts and the surrounding area clean. Sawdust buildup can affect the Fit and performance of the insert. Utilize a brush or vacuum to eliminate garbage regularly.

Use Proper Safety Gear: Wear appropriate safety gear, including well-being glasses and hearing security, while working woodworking tools with zero clearance inserts. Safety should always be a priority.

Mind the Kerf Width: If you’re making repeated cuts and the kerf (width of the cut) widens over time due to the zero clearance insert’s wear, replace the insert to maintain tight tolerances.

Material Compatibility: Ensure that your zero clearance insert suits your cutting material. Different materials may require specific types of inserts for optimal performance.

Alignment and Calibration: Regularly check the alignment and calibration of your woodworking tools. Misaligned tools can stress zero clearance inserts and affect their performance.

Storing Inserts: Store spare zero clearance inserts in a dry and clean environment to prevent warping or damage.

Conclusion

Bosch miter saw zero clearance insert is a valuable accessory for woodworking enthusiasts seeking precision, safety, and improved cut quality with their Bosch miter saws. This simple yet effective insert minimizes tear-out, reduces the risk of material getting stuck, and supports delicate workpieces.

Its ease of installation and compatibility with various Bosch miter saw models make it a worthwhile addition to any woodworking toolkit. Whether tackling intricate trim work or larger construction projects, the Bosch miter saw zero clearance insert can help you achieve cleaner, more accurate cuts while enhancing your overall woodworking experience.