Whether you’re a seasoned DIY enthusiast or a novice looking to tackle your first home improvement project, mastering the art of making precise and straight cuts with this versatile power tool is essential.

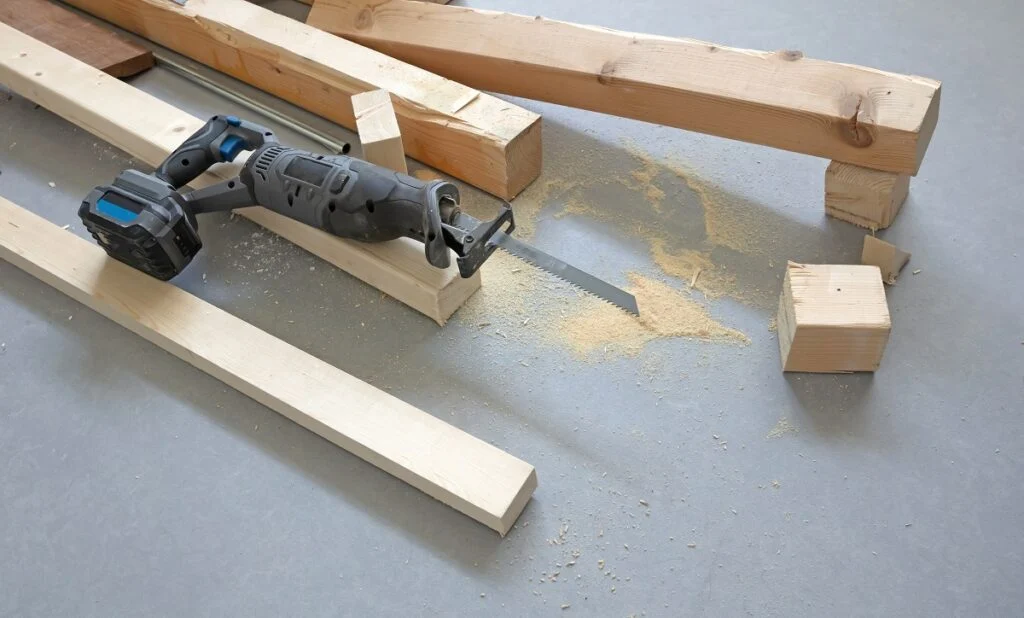

A reciprocating saw, often called a “recip saw” or “sawzall,” is a go-to choice for cutting through various materials, from wood and metal to plastic and PVC pipes.

However, achieving straight and accurate cuts can be challenging without the right techniques and tips. In this guide, we’ll walk you through the steps and provide valuable insights to help you cut straight and confidently with your reciprocating saw, ensuring your projects turn out safe and professional. So, let’s dive in and learn how to cut straight with a reciprocating saw?.

Reciprocating Saw Setup

Setting up a reciprocating saw adequately is crucial for safe and effective operation. Whether you’re about to start a project or you’re new to using this versatile tool, here’s a step-by-step guide on how to set up a reciprocating saw:

1. Safety First

Before you even touch the tool, make sure you’re wearing appropriate safety gear. This should include safety glasses or goggles, hearing protection, and work gloves.

2. Choose the Right Blade

Select a reciprocating saw Blade suitable for the material you intend to cut. Different blades are designed for cutting wood, metal, plastic, or other materials. Ensure the Blade is compatible with your saw’s chuck or blade holder.

3. Disconnect the Power Source

If your reciprocating saw is corded, unplug it from the power source. If it’s cordless, remove the battery to prevent accidental starts.

4. Install the Blade

Most reciprocating saws have a quick-release chuck or blade holder for easy installation. Follow these steps:

- a. Push the blade release button, if present, to release the current Blade.

- b. Insert the new Blade into the chuck, ensuring it’s fully seated and securely in place.

- c. Release the blade release button to lock the Blade in position.

5. Check Blade Orientation

Ensure the teeth on the Blade are facing in the correct direction. For most reciprocating saws, the teeth should be pointing toward the front of the tool to ensure proper cutting action.

6. Adjust the Shoe or Footplate

Some reciprocating saws have an adjustable shoe or footplate. This can be adjusted to control the cut’s depth or maintain stability during cutting. Set the shoe to the appropriate position for your task.

7. Power Up the Saw

If you have a cordless saw, insert a fully charged battery. Plug in your corded saw and ensure the power switch is in the “OFF” position.

8. Test the Saw

Before starting your project, briefly engage the trigger to ensure the saw works correctly and the Blade is secure.

9. Position Yourself and the Workpiece

Stand in a stable and balanced position with a firm grip on the saw’s handle. Position the saw and the workpiece to ensure a safe and controlled cut. Make sure the area is clear of any obstructions or hazards.

10. Begin Cutting

Use even pressure and maintain Control throughout the cut. Keep both hands on the saw for stability.

How To Cut Straight With A Reciprocating Saw?

Achieving straight and accurate cuts with a reciprocating saw can be challenging, but with the right techniques and some practice, you can improve your cutting precision. Here’s a step-by-step guide on how to cut straight with a reciprocating saw:

1. Choose the Right Blade:

Select the appropriate Blade for the material you’re cutting. Use a fine-tooth blade for cutting wood and a coarse-tooth blade for cutting metal or plastic. Make sure the Blade is sharp and in good condition.

3. Secure Your Workpiece:

Clamp your workpiece securely to a stable surface or workbench. This will prevent it from moving during the cut and ensure a straight line.

4. Position the Saw:

Position the reciprocating saw so the Blade aligns with your marked cutting line. Ensure the shoe or footplate of the saw is in contact with the workpiece to provide stability.

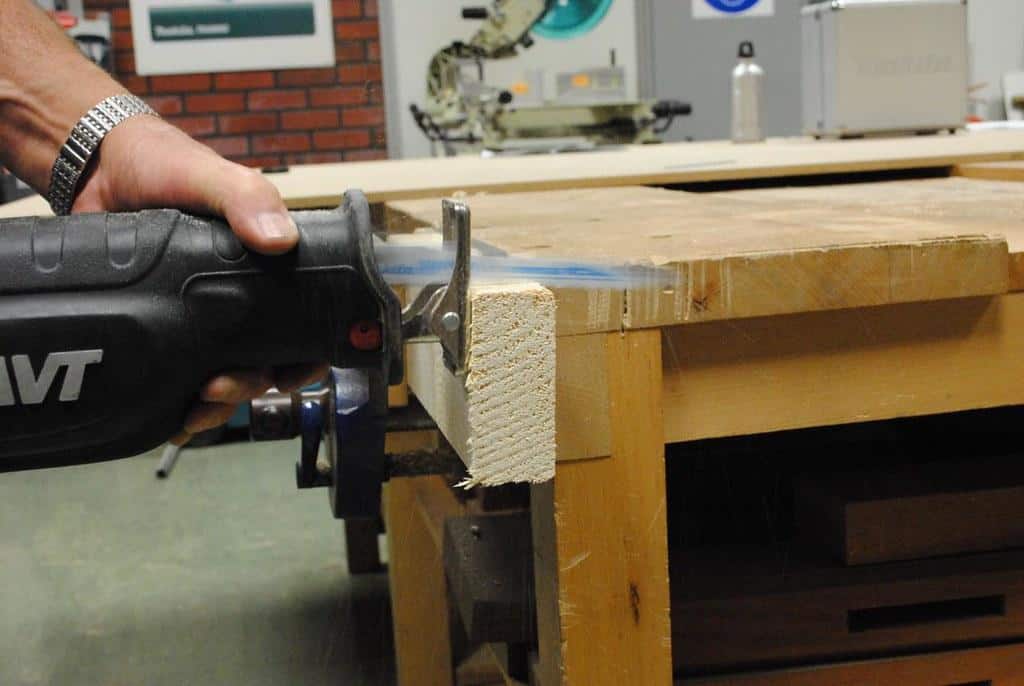

6. Use Both Hands:

Hold the reciprocating saw with both hands, one on the handle and the other on the front of the saw near the shoe. This grip provides better control and stability.

7. Start the Cut:

Start the saw with a gentle squeeze of the trigger. Allow the saw to reach full speed before making contact with the workpiece.

8. Apply Even Pressure:

Apply even pressure to the saw as you guide it along the marked cutting line. Let the saw’s Blade do the cutting.

9. Maintain Control:

Keep a steady hand and focus on following the marked line. Use slow and controlled movements to ensure a straight cut. If the saw starts to veer off track, gently correct its path.

10. Practice Short Strokes:

Use short, controlled strokes rather than long continuous cuts for more precise Control. This allows you to make adjustments as needed and maintain accuracy.

11. Follow Through:

Continue cutting along the entire length of the marked line. Keep your focus on maintaining a straight path and a steady hand.

12. Shut Off the Saw:

After completing the cut, release the trigger to shut off the saw. Wait for the Blade to come to a complete stop before setting it down.

13. Inspect Your Cut:

After cutting, inspect the workpiece to ensure the cut is straight and meets your requirements. Sand or file any rough edges if necessary.

Reciprocating saw-cutting tips

To achieve the best results when using a reciprocating saw, it’s essential to follow some cutting tips and techniques. These tips will help you make cleaner, more efficient cuts and ensure safety during your projects. Here are some reciprocating saw-cutting tips:

Choose the Right Blade

Select the appropriate Blade for the material you’re cutting. Different blades are designed for wood, metal, plastic, or demolition work. Using the right Blade ensures efficient cutting and prolongs blade life.

Inspect and Replace Blades

Check the condition of your saw blade before each use. Replace worn or damaged blades to maintain cutting efficiency and safety.

Secure the Workpiece

Secure your workpiece with clamps or a vice to prevent it from moving during the cut. This ensures greater control and safety.

Mark Your Cut Line

Use a pencil, chalk, or masking tape to mark the cutting line on the material. This helps guide your saw and ensures accuracy.

Use Short Strokes

Use short, controlled strokes rather than long, continuous cuts for better control and accuracy. Short strokes allow you to make adjustments and maintain a straight line.

Maintain Proper Blade Angle

Keep the reciprocating saw perpendicular to the workpiece for straight cuts. For bevel cuts or curves, adjust the angle as needed.

Let the Saw Do the Work

Avoid applying excessive force or pressure on the saw. Let the Blade’s cutting action do the work. Excessive force can lead to blade bending, binding, or breaking.

Cut at an Angle for Faster Cutting

You can start the cut at a slight angle to cut through thicker materials more quickly. Once the Blade is partially into the material, gradually bring it to a perpendicular position for a straight cut.

Support Thin or Flexible Materials

When cutting thin or flexible materials like pipes or tubing, use a support block or another material underneath to prevent vibration and ensure a clean cut.

Clear the Cutting Area

Remove any debris or obstructions from the cutting area to prevent the Blade from getting caught during the cut.

Wear Appropriate Safety Gear

Always wear safety goggles, ear protection, gloves, and a dust mask when using a reciprocating saw. Safety gear is crucial to protect against flying debris, noise, and dust.

Plan Your Cuts

Think about the direction and sequence of your cuts before starting. Plan your cutting path to minimize unnecessary movements and ensure a smoother process.

Regularly Lubricate the Blade

Applying a lubricant or cutting oil to the Blade can reduce friction and heat buildup, prolonging the life of the Blade and making cuts smoother.

Maintaining a Straight Cut

A. Focus on Your Cutting Line

- Constantly Monitor: Keep your eyes on the marked cutting line throughout the cut.

- Visual Guides: Use any available visual guides, such as pencil marks or reference lines, to help you stay on track.

- Steady Hands: Keep a steady hand on the saw, maintaining a firm grip to minimize vibrations.

B. Blade Alignment

Keep the Blade Aligned: Ensure that the Blade remains parallel to the marked cutting line.

Adjust as Needed: Make minor adjustments to the angle and direction of the saw to realign it with the cutting line if you start to veer off course.

C. Controlled Movements

Smooth Movements: Maintain a controlled, smooth motion while cutting, avoiding sudden jerks or aggressive movements.

Minimal Pressure: Apply only enough pressure to guide the saw through the material; avoid pushing or forcing it, which can lead to inaccuracies.

D. Use a Guide or Fence

Straightedge or Fence: Use a straightedge or a fence as a guide to help you maintain a straight path while cutting.

Clamping: Secure the guide or fence to prevent movement during the cut.

E. Make Incremental Adjustments

Minor Corrections: If you start deviating from the cutting line, gradually adjust to bring the saw back on course.

Pause if Necessary: Don’t hesitate to pause the cut briefly if you need to readjust your position or angle.

F. Practice

Practice Makes Perfect: Cutting straight with a reciprocating saw can be challenging, especially for beginners. Regular practice will improve your skills and accuracy over time.

Test Cuts: Consider making test cuts on scrap material to gain confidence and hone your technique before tackling essential projects.

G. Maintain a Stable Workpiece

Secure the Material: Ensure that the material you’re cutting is firmly secured to prevent movement, which can lead to uneven cuts.

Support from Below: If possible, support the material from underneath to minimize vibrations and wobbling.

H. Check Your Progress

Frequent Checks: Stop and check your progress against the cutting line to ensure you stay on track.

Course Correction: Make any necessary adjustments to maintain a straight path.

I. Patience

Take Your Time: Cutting straight requires patience and a steady hand. Rushing through the cut can lead to mistakes and inaccuracies.

Focus on Precision: Emphasize the importance of precision over speed when using a reciprocating saw.

The Cons of Using a Reciprocating Saw

- While a reciprocating saw is a versatile and powerful tool with numerous advantages, here are some cons of using a reciprocating saw:

- Inaccuracy in Straight Cuts: Achieving perfectly straight cuts can be challenging, especially for beginners. The saw blade can easily deviate from the desired cutting line without a guide or fence.

- Vibrations and Fatigue: Reciprocating saws produce significant vibrations during use, leading to user fatigue and discomfort, particularly during prolonged cutting sessions.

- Limited Precision: While reciprocating saws excel at rough cuts and demolition work, they may not provide the precision required for fine woodworking or detailed projects.

- Risk of Blade Binding: When cutting through dense materials or making long cuts, there is a risk of the blade binding or getting stuck, which can be dangerous and potentially damage the saw.

- Noise and Disturbance: Reciprocating saws can be loud, leading to noise complaints in residential areas or disturbing others in a shared workspace.

- Limited Blade Life: Cutting through rigid materials like metal or masonry can significantly reduce the lifespan of reciprocating saw blades. Replacing blades can be costly, mainly if you use the tool frequently.

- Not Ideal for Intricate Cuts: Reciprocating saws are not the best choice for making intricate or curved cuts. Other tools like jigsaws or scroll saws are better suited for such tasks.

Safety and Cleanup

A. Safety Procedures

- Wait for the Blade to Cool: After completing your cuts, allow the Blade to cool down before touching it to avoid burns.

- Disconnect Power: Unplug your reciprocating saw from the power source if it is corded. If it’s cordless, remove the battery.

- Store Safely: When not in use, store your reciprocating saw safely and securely away from children and unauthorized users.

- Inspect the Saw: Inspect the saw for any damage, wear, or loose parts. Replace or repair as needed to maintain safety.

B. Cleanup

Clear Work Area: Remove any remaining debris or offcuts from the workspace to prevent tripping hazards or interference with your next task.

Dispose of Debris Properly: Place sawdust, metal shavings, and other debris in appropriate containers or trash bags for disposal. Follow local regulations for hazardous materials if necessary.

Clean the Saw: Wipe down the reciprocating saw to remove dust and residue. Use a brush or compressed air to clean hard-to-reach areas.

Blade Handling: Be cautious when handling used blades; they can be sharp. Use a blade disposal container or wrap them in cardboard to prevent accidental cuts.

Safety Gear Removal: Carefully remove your safety gear (goggles, ear protection, gloves), taking care not to contaminate yourself with dust or debris.

Inspect Your Work: Examine your work area to ensure no tools or materials are left behind, and it’s safe for others.

Secure the Saw: If you have multiple tools in your workspace, ensure the reciprocating saw is safely stored or secured to prevent accidental activation or damage.

C. Additional Safety Tips

Maintain First Aid Supplies: Keep a first aid kit nearby in case of accidents.

Proper Blade Disposal: Dispose of old or damaged blades in a designated disposal container or take them to a recycling facility if applicable.

Personal Cleanup: After completing your work, wash your hands and face to remove any lingering dust or debris.

Regular Maintenance: Inspect and maintain your reciprocating saw to ensure it remains safe and operational.

Conclusion

Mastering the art of cutting straight with a reciprocating saw is essential for anyone working with this versatile tool. It ensures precision in your projects and contributes to safety and efficiency.

Remember the importance of safety, preparation, and equipment maintenance for the best results. Whether you’re a beginner or an experienced DIY enthusiast, the ability to cut straight with a reciprocating saw is a valuable asset that will serve you well in various home improvement and construction tasks.