If you’re an avid DIY enthusiast or a professional woodworker, you likely understand the importance of maintaining sharp tools for optimal performance. One such tool that often requires attention is the circular saw blade.

We’ll walk you through the step-by-step process of sharpening your circular saw blade, helping you maintain its effectiveness and achieve clean, accurate cuts. So, let’s dive in and discover how to sharpen a circular saw blade effectively.

Preparing for Sharpening

Before sharpening a circular saw blade, it is essential to prepare for the task properly. This ensures the best possible results and reduces the risk of accidents or damage to the edge.

- Gather the necessary tools: To begin, gather all the tools and equipment required for sharpening a circular saw blade. Protect your eyes and hands from potential flying debris or sharp edges. Use a stiff-bristle brush to remove debris or resin buildup from the blade.

Secure the circular saw blade in place for stability during sharpening. Choose a suitable file or grinder based on the blade type and your preference. Use a lubricant such as WD-40 or cutting oil to reduce friction and prevent overheating during sharpening.

- Ensure safety precautions: Sharpening a circular saw blade involves handling sharp tools and rotating machinery. Adhering to safety precautions is crucial. Take the following measures: a. Perform the sharpening process in a space with good airflow to minimize the inhalation of dust or fumes.

Make sure the circular saw blade is securely mounted in the blade clamp or vise before sharpening. Wear safety goggles and gloves to safeguard your eyes and hands from hazards. Unplug your Circular saw from the power source if it is corded. For cordless saws, remove the battery to prevent accidental activation.

- Clean the blade: Before sharpening, it is crucial to clean the circular saw blade. Use a stiff-bristle brush to remove sawdust, resin, or other debris accumulated on the teeth or the blade surface. Cleaning the edge ensures a more effective sharpening process.

Proper preparation is essential before sharpening a circular saw blade. Gathering the necessary tools, following safety precautions, and cleaning the blade can ensure a smoother and safer sharpening process.

Assessing the Blade Condition

Before sharpening a circular saw blade, it is crucial to assess its condition. Examining the edge allows you to determine if it is suitable for sharpening or requires replacement. Setting the blade condition ensures you invest time and effort in sharpening blades worth salvaging.

- Inspect the blade for damage: Carefully examine the circular saw blade for wear. Look for chips, cracks, missing or broken teeth, or other visible abnormalities. If the edge has significant damage, it may not be feasible to sharpen it effectively. In such cases, it is recommended to replace the blade.

- Check the blade’s overall condition: Evaluate the overall condition of the edge. Look for excessive wear, uneven or dull teeth, extreme heat, or burning signs. If the bite is severely worn or the teeth are beyond repair, it may be more practical to replace it rather than attempting to sharpen it.

- Assess the blade’s thickness: Measure the thickness of the circular saw blade using a caliper or a micrometer. Most manufacturers specify the original thickness of the blade. If the edge has worn significantly and its thickness is below the recommended level, it may not be suitable for sharpening. Thinning blades may compromise their structural integrity and cutting performance, warranting a replacement.

- Consider the cost-effectiveness: Evaluate the cost-effectiveness of sharpening the blade. If the edge is of high quality and expensive, it may be worth investing in sharpening. However, if it is a low-cost or low-quality blade, it might be more cost-effective to replace it instead.

Assessing the condition of a circular saw blade before sharpening is crucial to determine if it is worth the effort and to ensure optimal cutting performance. By inspecting the blade for damage, evaluating its overall condition, checking its thickness, and considering its cost-effectiveness, you can decide whether to sharpen the blade or replace it.

Choosing the Right Sharpening Method

Selecting the appropriate sharpening method for a circular saw blade is essential to achieve optimal results and extend the blade’s lifespan. Different sharpening techniques are available, each with its advantages and considerations.

- Manual sharpening with a file: Suitable This method suits individuals with experience with hand tools and prefers a more traditional approach.

Process: Secure the Circular saw blade in a vise or blade clamp. Use a file designed for saw blades and follow the existing tooth angle. Apply firm and consistent pressure while filing each tooth individually. Maintain a consistent stroke and rise throughout the process.

Considerations: Manual sharpening a file requires patience, skill, and attention to detail. It is time-consuming and may be challenging for beginners or those who need prior experience.

- Using a sharpening machine or jig: Suitable This method is suitable for individuals who prefer a more automated and precise approach to sharpening circular saw blades.

Process: Utilize a sharpening machine or a specialized jig for circular saw blades. These machines or jigs offer guided sharpening with adjustable angles and provide consistent results.

Considerations: A sharpening machine or jig can be more efficient and accurate than manual sharpening. However, these tools may require an initial investment, and proper setup and adjustment are crucial for optimal results.

- Professional sharpening services: Suitable This option is suitable for individuals who prefer to entrust the sharpening process to professionals or those who lack the necessary tools, skills, or time to sharpen the blade themselves.

Strategy: Seek out a reputable sharpening service specializing in circular saw blades. They have the expertise and equipment to sharpen the knife correctly. Please consult the service provider regarding their process, turnaround time, and cost.

Considerations: Professional sharpening services can save time and ensure high-quality results. However, it may involve additional costs, and you will need to rely on the skills and expertise of the service provider.

Choosing the right sharpening method for a circular saw blade depends on personal preference, skill level, and the condition of the edge. Whether you opt for manual sharpening with a file, using a sharpening machine or jig, or seeking professional sharpening services, ensure that the chosen method aligns with your needs and provides the desired precision and efficiency.

Sharpening Process

The sharpening process for a circular saw blade involves precise steps to restore the cutting edges and improve the blade’s performance. Following a systematic approach ensures effective sharpening and extends the blade’s lifespan.

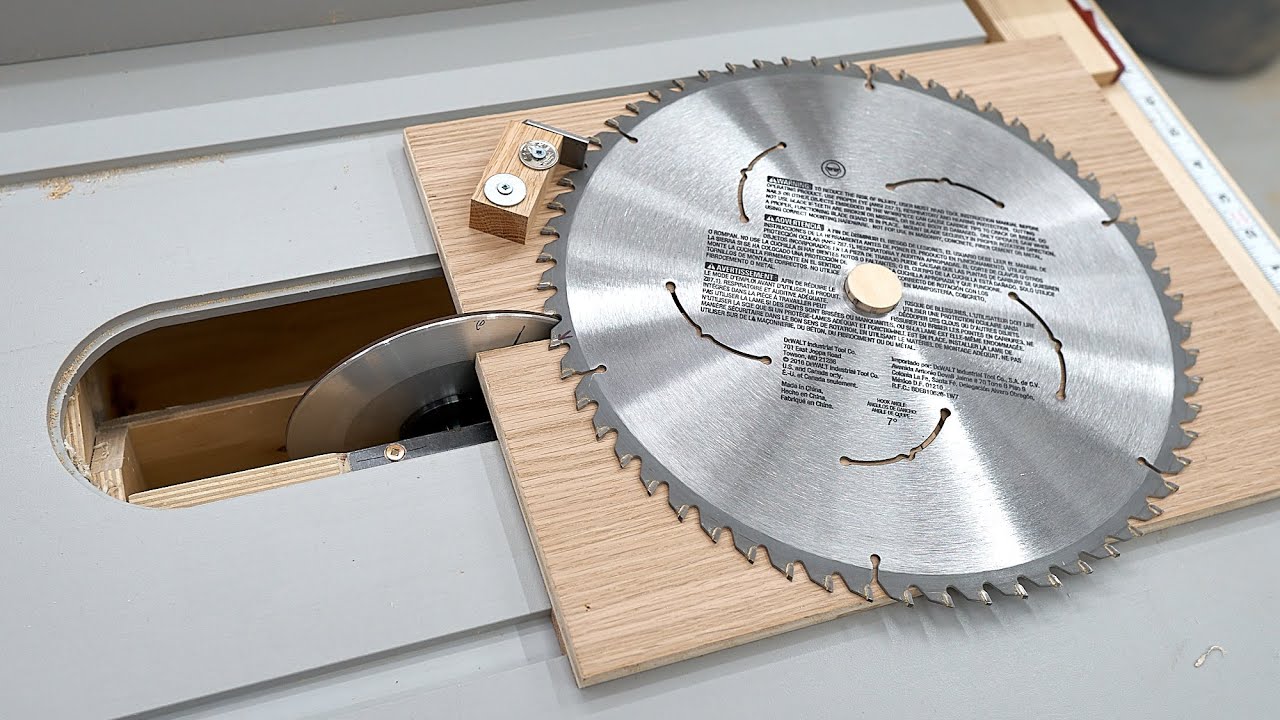

- Secure the blade: Start by securely clamping the Circular saw blade in a vise or a clamp. Ensure that it is stable and firmly held to prevent any movement or accidents during the sharpening process. Make sure the teeth are facing upwards and easily accessible.

- Clean the blade: Before sharpening, use a stiff bristle or wire brush to remove debris, resin, or sawdust from the edge. Cleaning the edge allows for better visibility and ensures a smoother sharpening process.

- Determine the tooth angle: Circular saw blades have specific tooth angles, typically ranging between 10 to 25 degrees. Refer to the manufacturer’s guidelines or examine the existing tooth angles to determine the correct angle for sharpening. Maintaining the original tooth angle is crucial for optimal cutting performance.

- Sharpening method:

Manual sharpening with a file

- Use a flat or specialized saw file matching the tooth size.

- Position the file at the determined tooth angle and apply downward pressure.

- File each tooth individually, moving the file in a forward-backward motion.

- Maintain consistent pressure and strokes to ensure constant sharpening.

Sharpening machine or jig

- If using a sharpening machine or jig, follow the manufacturer’s instructions for setup and operation.

- Set the appropriate angle according to the tooth angle and adjust the machine or jig accordingly.

- Follow the recommended technique to guide the blade through the device or jig for precise sharpening.

- Repeat the process for each tooth until the desired sharpness is achieved.

Professional sharpening services

- If utilizing professional sharpening services, submit the blade to the service provider.

- They will use specialized equipment and expertise to sharpen the blade according to industry standards.

- Communicate any specific requirements or concerns to the service provider.

- Collect the sharpened blade within the designated turnaround time.

- After sharpening, test the blade: carefully remove the sword from the vise or clamp. b. Inspect the teeth for sharpness and uniformity. Run your finger gently along the cutting edges to check for smoothness. c. Reinstall the blade onto the circular saw and perform test cuts on scrap wood to evaluate the cutting performance and ensure satisfactory results.

The sharpening process for a circular saw blade involves securing the edge, cleaning it, determining the tooth angle, selecting the appropriate sharpening method (manual, machine/jig, or professional service), and testing the sharpened blade for performance.

Testing the Sharpness

After sharpening a circular saw blade, testing its sharpness before returning it to regular use is crucial. Testing ensures the blade is properly sharpened and ready for optimal cutting performance.

- Inspect the blade: Before testing the sharpness, visually inspect the circular saw blade for any signs of uneven sharpening or damage. Look for consistent sharpening across all teeth and ensure no chips, cracks, or other defects that may affect performance.

- Conduct a visual examination: Hold the circular saw blade up to a well-lit area and examine the cutting edges of the teeth. The sharpened edges should appear clean and defined without any visible irregularities. The teeth should have a consistent shape and sharpness.

- Perform a tactile test: Using gloves for safety, carefully run your finger gently along the cutting edges of the teeth. Be cautious and avoid applying excessive pressure to prevent injury. The sharpened edges should feel smooth and free from any roughness or jaggedness. They should be sharp enough to catch on your fingertip without causing discomfort or pain.

- Conduct test cuts: Place a piece of scrap wood or material similar to the ones you commonly work with on a stable surface. Position the circular saw on the material and align the blade with the marked cutting line.

Activate the saw and make a series of test cuts, paying attention to the ease and smoothness of the cutting process. Observe the quality of the cuts, looking for clean and precise results. Note any signs of burning, excessive vibration, or difficulty making the cuts.

- Assess the results: Evaluate the quality of the test cuts. A sharp circular saw blade should effortlessly cut through the material with minimal resistance. The cuts should be clean and free from splintering or tearing. Consider the overall performance and compare it to your expectations and previous experience with the blade.

The sharpened blade is deemed sufficiently sharp if it meets or exceeds your requirements. If the performance is unsatisfactory, further sharpening or adjustments may be necessary.

Testing the sharpness of a circular saw blade is crucial to ensure its effectiveness and cutting performance. By visually examining the knife, conducting a tactile test, and performing test cuts on scrap material, you can assess the sharpness and quality of the sharpened edge.

The blade is ready for regular use if it passes the tests by exhibiting smooth and precise cutting performance. However, further sharpening or adjustments may be required if the results could be better. Remember to prioritize safety while testing the blade and always follow the manufacturer’s guidelines for maintenance and usage.

Maintenance and Storage Tips

Proper maintenance and storage of a circular saw blade are essential to prolonging its lifespan, ensuring optimal performance, and maintaining its cutting efficiency. Following these maintenance and storage tips will help keep the edge in excellent condition for future use.

- Clean the blade after each use: After using the circular saw, clean the edge to remove any debris, sawdust, or resin that may have accumulated. Use a stiff-bristle brush or a dedicated blade cleaning solution to scrub the blade’s teeth and surface gently. Ensure the edge is dry before storing it.

- Inspect the blade regularly: Inspect the blade for any signs of damage, such as chipped or missing teeth, cracks, or warping. Damaged blades should be replaced promptly to prevent accidents or poor cutting performance.

- Sharpen the blade as needed: Monitor the blade’s cutting performance and sharpen it when necessary. Dull blades can strain the saw and lead to rough cuts or overheating. Follow the recommended sharpening techniques in this guide or refer to the manufacturer’s guidelines.

- Proper blade storage: Store the circular saw blade in a clean, dry, and well-ventilated area. Keep the blade in its protective casing or cover to prevent it from coming into contact with other tools or surfaces that could damage the teeth. b. Avoid storing the blade in damp or humid environments, leading to corrosion or rust. If keeping multiple blades, ensure they are separated to prevent contact or potential damage.

- Handle with care: Use gloves and caution to avoid accidental cuts or injuries when handling the blade. Handle the blade by the edges and avoid touching the sharp cutting teeth.

- Follow manufacturer’s guidelines: Refer to the manufacturer’s instructions for any specific maintenance recommendations or restrictions for the particular Circular saw blade you are using. They may provide additional tips or guidelines to ensure the longevity and performance of the blade.

- Professional servicing: If you need clarification on performing maintenance tasks or need specialized maintenance, consider seeking professional servicing. Professional blade sharpening or maintenance services can ensure that the blade is properly cared for and maintained by experts in the field.

Proper maintenance and storage of a circular saw blade are crucial for its longevity and cutting performance. By cleaning the edge after each use, inspecting it regularly, sharpening when needed, storing it in a suitable environment, handling it carefully, and following the manufacturer’s guidelines, you can extend the blade’s lifespan and maximize its cutting efficiency.