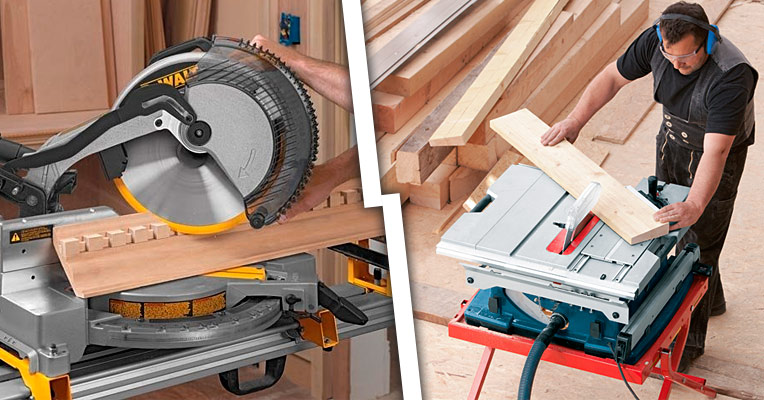

Miter Saw Specifications

- Cuts: Miter saws excel at making miter cuts (angled cuts) and bevel cuts (angled cuts along the thickness) in various materials, primarily wood.

- Versatility: These saws offer versatility with the ability to make miter cuts, bevel cuts, and straight crosscuts, enabling precise work on a variety of projects.

- Adjustability: They feature mechanisms for adjusting the miter angle (left or right) and the bevel angle, providing flexibility in achieving desired cutting angles.

- Applications: Known for their accuracy, miter saws are indispensable for framing, molding installation, furniture making, and more in woodworking and construction.

- Safety: Modern miter saws come equipped with safety features such as blade guards and electric brakes for user protection.

- Variety: Various miter saw models are available, catering to different cutting needs, from standard models to sliding compound and dual-bevel miter saws.

Table Saw Specifications

- Precision: Table saws are renowned for their precision in making straight cuts, including rip cuts, cross cuts, and dado cuts, making them ideal for exacting woodworking projects.

- Safety: They prioritize user safety with features like blade guards, anti-kickback mechanisms, and emergency stop switches.

- Versatility: Table saws can perform various joinery operations and are adaptable for a wide range of woodworking tasks.

- Variety: Different types of table saws are available, from compact benchtop models for small workshops to heavy-duty cabinet table saws favored by professionals.

- Accessories: They can be enhanced with accessories and attachments to expand their functionality.

Circular Saw Specifications

- Portability: Circular saws are portable and preferred by contractors for their ability to be transported quickly to job sites.

- Cuts: They can facilitate a variety of straight cuts, including rip cuts parallel to the material’s grain, crosscuts perpendicular to the grain, bevel cuts, and compound cuts.

- Safety: Safety features like blade guards, anti-kickback mechanisms, and electric brakes enhance user safety.

- Versatility: Circular saws are indispensable for applications ranging from framing and roofing to general construction and woodworking tasks.

- Variety: There are various types of circular saws, each designed to meet specific needs, offering different levels of power, portability, and convenience.

- Understanding these key features will help you choose the right saw for your woodworking and DIY projects. Each of these saws has its strengths and applications, making them valuable tools in your toolkit.

Types of Models for Saws

- Benchtop Table Saw: Compact and portable, suitable for small workshops and job sites.

- Contractor Table Saw: Larger and more powerful, commonly used by contractors and woodworking enthusiasts.

- Cabinet Table Saw: Heavy-duty and high-powered, favored by professional woodworkers.

- Hybrid Table Saw: Combines features of contractor and cabinet saws.

- Portable Jobsite Table Saw: Designed for easy transport and used on job sites.

Accuracy of Saws

- Miter Saw: Known for precision and accuracy in angled cuts, making them ideal for tasks like trim work and molding installation.

- Table Saw: Exact for straight cuts and repeatable cuts, making them ideal for fine woodworking and cabinetry.

- Circular Saw: While capable of making precise cuts, they may require additional guides or jigs to achieve the same level of accuracy as miter and table saws.

Portability of Saws

- Miter Saw: Portable models are available for job site use, but stationary versions are expected in workshops.

- Table Saw: Various models offer different levels of portability, from lightweight benchtop saws to heavier cabinet saws.

- Circular Saw: Highly portable and suitable for use in diverse locations, making them favored by contractors and DIY enthusiasts.

Versatility of Saws

- Miter Saw: Ideal for precise angled cuts.

- Table Saw: Excels in straight cuts and joinery work.

- Circular Saw: Offers versatility and portability for a wide range of cutting tasks.

Safety Considerations while using Saws

Circular Saw: Safety features such as blade guards and anti-kickback mechanisms are essential when using circular saws.

Miter saws are ideal for precise angled cuts; table saws excel in straight cuts and joinery work. In contrast, circular saws offer versatility and portability for a wide range of cutting tasks.

The choice depends on the specific cutting requirements and the precision needed for the project. Many woodworkers and professionals find it beneficial to have multiple types of saws in their tool collection to cover various cutting needs.

Materials that can be cut down by Saws

- Wood: All three saw types (miter, table, and circular saw) can effectively cut wood. The choice depends on the specific tasks within the project.

- Sheet Materials: For cutting large sheets of plywood, MDF, or OSB, a table saws large table surface provides stability and accuracy.

- Metal or Plastic: When working with non-wood materials like metal or plastic, circular saws equipped with suitable blades for those materials may be necessary.

Precision and Accuracy

- Fine Woodworking: Projects requiring high precision, such as fine woodworking, cabinetry, and furniture making, often benefit from the accuracy of a table saw, or a compound miter saw.

- General Construction: A circular saw can provide cutting power and versatility in general construction tasks with less critical precision.

Portability of using Saws

- Workshop vs. Job Site: Consider whether the project is based in a workshop or on a job site. Table and miter saws are often stationary tools found in workshops, while circular saws are highly portable and suitable for on-site work.

- Transportation: The tool’s portability becomes crucial if your project requires you to transport the saw to different locations. In such cases, a portable table saw or circular saw is advantageous.

Safety Considerations

User Skill Level: Consider the skill level of the user. Some saws may be more user-friendly for beginners, while others require more experience and safety precautions.

Safety Features: Ensure that the chosen saw has adequate safety features, such as blade guards, anti-kickback mechanisms, and electric brakes, to mitigate potential hazards associated with the project.

Ultimately, the nature of your project should dictate your choice of saw, with careful consideration of the specific cutting requirements, materials, precision demands, portability needs, and safety considerations. In many cases, experienced woodworkers and professionals may use a combination of saws to ensure they have the right tool for each aspect of their project.

How might your budget determine the saw you can afford?

Your budget determines the saw you can afford for your woodworking or construction needs. Different types of saws come with varying price ranges, and your available budget will influence the features, quality, and brand of the saw you can purchase. Here’s how your budget may impact your choice of saw:

Basic vs. Premium Models

With a limited budget, you may have to opt for a primary or entry-level model of the saw type you need. These models often have fewer advanced features and may need more conveniences found in premium models.

A larger budget allows you to consider premium or higher-end models that offer enhanced performance, durability, and additional features. These saws are often better suited for professional use and more demanding projects.

Brand and Quality

Budget constraints can influence your choice of brands and the quality of the saw. Some well-known brands command higher prices due to their reputation for reliability and precision.

If your budget is limited, you may need to explore less expensive brands or consider refurbished or used saws to access higher-quality tools at a lower cost.

Type of Saw

Different types of saws have varying price points. For example, table saws, especially cabinet models, are more expensive than circular or basic miter saws.

Your budget may determine whether you can afford the type of saw that best suits your project needs. A more affordable alternative may be necessary if the ideal saw is beyond your budget.

Accessories and Extras

Consider that your budget covers the saw and any necessary accessories, blades, safety equipment, and maintenance tools. A limited budget may require you to prioritize essential accessories and postpone optional extras.

Used or Refurbished Options

You may explore used or refurbished saws if your budget is particularly tight. These can be cost-effective options to access higher-quality tools at a reduced price. However, ensure that the used saw is in good working condition and well-maintained.

Long-Term Investment

Remember that while budget constraints are essential, saws are an investment. It’s often worth considering spending a bit more to acquire a durable, reliable tool that will serve you well over the long term, especially if you plan to use it frequently.

Consider the guarantee and client care given by the producer when making your decision. Spending more on a saw with a good warranty can offer peace of mind and cost savings in the event of unexpected issues.

Your budget significantly influences the type of saw you can afford and the overall quality and features of the tool you acquire. It’s essential to balance your budget and project needs, ensuring that the saw you choose aligns with your requirements while being mindful of cost considerations.

How your skill level and experience should influence your choice?

Your skill level and experience should be crucial in determining the choice of saw you use for woodworking or construction projects.

The right tool should align with your proficiency and comfort level to ensure safety, efficiency, and the quality of your work. Here’s how your skill level and experience should influence your choice of saw:

Beginners and Novices

Skill Level: If you are a beginner or novice with limited experience in using power tools, it’s essential to prioritize safety and ease of use. Consider user-friendly tools that have clear instructions and are less complex.

Recommended Saw Types: Tools like circular or basic miter saws are a good starting point for beginners. They are relatively simple to operate and allow you to develop fundamental cutting skills before moving on to more advanced tools.

Safety: Pay close attention to safety features and take the time to learn and practice safe operating procedures.

Intermediate Woodworkers

Skill Level: As you gain experience and confidence, you can explore more versatile and precise tools. It would help if you were comfortable with basic cutting techniques and safety practices.

Recommended Saw Types: Intermediate woodworkers can consider compound miter saws, sliding compound miter saws, or benchtop table saws. These tools offer greater versatility and precision for a broader range of projects.

Advanced Techniques: With an understanding of more advanced woodworking techniques, you can explore features like bevel cuts and compound angles.

Advanced and Professional Woodworkers

Skill Level: Advanced and professional woodworkers have mastered various cutting techniques, including joinery and intricate detailing. They have a deep understanding of woodworking principles and safety.

Recommended Saw Types: For advanced users, cabinet table saws, dual-bevel sliding compound miter saws, and other high-end tools provide the precision and power required for professional-level work.

Customization: Experienced users can customize and fine-tune their tools to meet specific project requirements.

Safety Considerations

- Regardless of skill level, safety should always be a top priority. Experienced users should continue to adhere to safety practices and encourage proper safety habits in their workshops.

- Users of all skill levels should wear fitting wellbeing gear, including eye and ear assurance and dust masks when necessary.

Learning and Growing

Consider that your saw choice should allow room for growth and skill development. As you gain experience and take on more complex projects, your tool collection can expand to include a wider variety of saws and other woodworking euipment.

Conclusion

Your skill level and experience should guide your saw choice, emphasizing safety, ease of use, and alignment with your current abilities. As your skills evolve, you take on additional complex tasks; you can put resources into more advanced tools that match your growing expertise. Always prioritize safety, regardless of your skill level, and continue to learn and improve your woodworking skills over time.