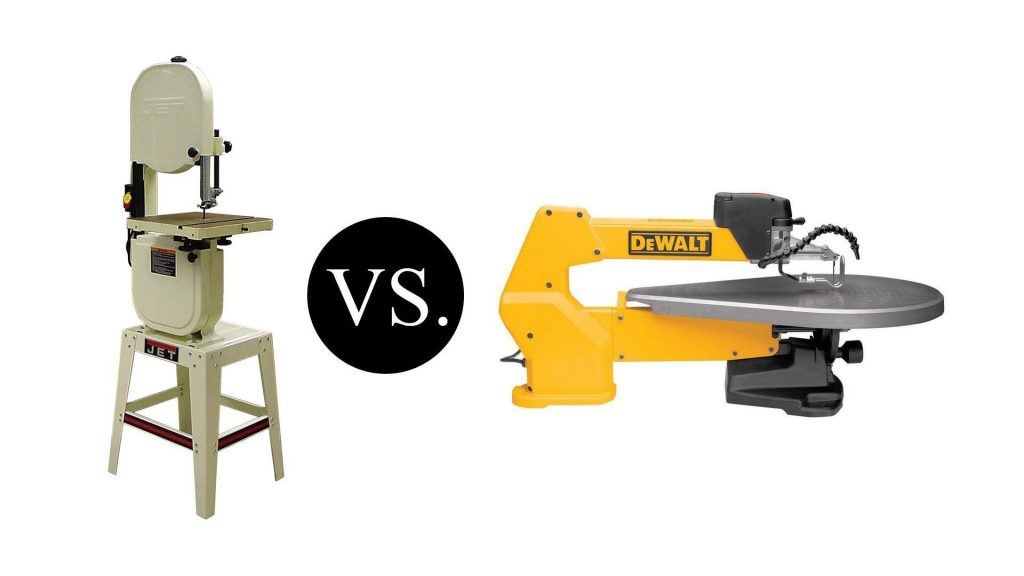

A scroll saw, and a table saw are both woodworking tools, but they serve different purposes and have distinct features. Here’s a comparison of the two: ( Scroll saw vs. table saw )

1. Purpose:

Scroll Saw: A scroll saw is primarily used for intricate and detailed curved cuts in thin materials like wood, plastic, and thin metals. It’s commonly used for making intricate designs, fretwork, and precise interior cuts.

Table Saw: A table saw is designed for making straight, rip, and crosscuts in larger pieces of lumber or sheet goods. It’s used for cutting boards to size, ripping long pieces, and creating straight-edged pieces.

2. Cutting Mechanism:

· Scroll Saw: It features a thin, narrow blade that moves up and down rapidly. The blade allows for precise and intricate cuts with the ability to make tight curves.

· Table Saw: It uses a circular saw blade that protrudes above the table’s surface. The blade is best suited for straight cuts and unsuitable for intricate designs or curves.

3. Versatility:

· Scroll Saw: It is versatile for making curved and intricate cuts, including internal cuts. It’s often used for crafts, scrollwork, and small woodworking projects.

· Table Saw: While it excels at straight cuts, it lacks the versatility to make curved or internal cuts. However, with various accessories and jigs, it can be adapted for specific angled and beveled cuts.

4. Safety:

· Scroll Saw: Generally considered safer than a table saw, as the blade is enclosed and operates within a small space. It’s less likely to cause kickbacks or serious injuries.

· Table Saw: Table saws can be more dangerous due to their exposed spinning blade. Kickback is a potential hazard requiring more caution and safety measures.

5. Size and Portability:

· Scroll Saw: Typically smaller and more portable, making it easier to move around and store when not in use.

· Table Saw: Larger and heavier, often requiring a dedicated workspace in a workshop or garage.

6. Cost:

· Scroll Saw: Generally less expensive than table saws, making it a good choice for hobbyists and those focused on detailed craftsmanship.

· Table Saw: Tends to be more expensive, especially for high-quality models with advanced features.

Table saw

A table saw is a versatile woodworking tool for making straight, rip, cross, and beveled cuts in various types of wood and other materials. It is a flat, horizontal table with a circular saw blade protruding through the surface. Here are some key features and information about table saws:

1. Components:

· Table: The flat, rectangular surface that supports the material being cut. It often has extensions to accommodate larger workpieces.

· Blade: A circular saw blade that protrudes above the table. The blade can be adjusted in height and angle to make different cuts.

· Fence: A guide parallel to the blade that ensures straight and accurate rip cuts.

· Miter Gauge: A tool used for making crosscuts and angled cuts. It fits into slots on the table and can be adjusted to various angles.

· Motor: The motor powers the blade and varies in horsepower (HP) depending on the saw’s size and intended use.

2. Types of Table Saws:

· Contractor Table Saw: Portable and suitable for job sites, these saws have an open, folding stand and a powerful motor.

· Cabinet Table Saw: Heavy-duty, stationary saws with an enclosed base, offering stability and precision. They are commonly used in professional workshops.

· Hybrid Table Saw: Combines contractor and cabinet saw features, offering a compromise between power and portability.

· Portable/Tabletop Table Saw: Lightweight and compact for easy transport and small-scale projects.

3. Common Uses:

- Rip Cuts: Cutting material along its length, typically with the grain.

- Crosscuts: Cutting material across its width, often at a 90-degree angle to the grain.

- Bevel Cuts: Tilting the blade to make angled cuts.

- Dado and Rabbet Cuts: Creating grooves or channels in the wood for joinery.

- Miter Cuts: Cutting at precise angles for creating corners, frames, or complex shapes.

- Joinery: Table saws make joints like tenons and half-lap joints.

4. Safety Considerations:

- Always use appropriate safety gear, including safety glasses and hearing protection.

- Keep the work area clean and well-lit.

- Ensure the saw is properly adjusted and maintained.

5. Table Saw Accessories:

· Various accessories, such as dado blade sets, feather boards, and sleds, can enhance the versatility and safety of a table saw.

Advantages and disadvantages of table saw vs. Scroll saw

Indeed, let’s explore the advantages and disadvantages of both table saws and scroll saws:

Table Saw:

Advantages:

1. Speed: They are generally faster at making straight cuts than scroll saws, which makes them efficient for projects requiring many repetitive cuts.

2. Accuracy: Table saws are known for their precision, allowing for consistent and accurate cuts, mainly when using a fence or miter gauge.

3. Power: They typically have more powerful motors, making them capable of handling thicker and more complex materials.

4. Dado Capability: Table saws are well-suited for making dado cuts, essential for joinery and furniture construction.

Disadvantages

1. Lack of Intricacy: Table saws are not designed for intricate or curved cuts, making them less suitable for detailed work.

2. Safety Concerns: They can be more dangerous due to the exposed blade, with a higher risk of kickback and severe injuries if misused.

3. Size and Portability: Table saws are more extensive and less portable than scroll saws, requiring dedicated workshop space and often weighing more.

Scroll Saw

Advantages:

1. Intricate Cuts: Scroll saws excel at making highly detailed, intricate cuts, including tight curves and intricate patterns. They are ideal for decorative and artistic woodworking.

2. Control: They offer excellent control over the cutting process, allowing for internal cuts and following complex outlines.

3. Safety: Scroll saws are generally considered safer than table saws due to the enclosed blade and lower risk of kickback.

4. Quiet Operation: They tend to be quieter, which can be more suitable for indoor or shared workspaces.

5. Small Size and Portability: Scroll saws are compact and portable, making them suitable for hobbyists and those with limited workspace.

Disadvantages:

1. Limited Thickness: Scroll saws are typically designed for thinner materials like wood, plastic, and thin metals. They are not suitable for cutting thick lumber.

2. Slower: They are slower at making cuts than table saws, which can be a drawback for large projects or straight cuts.

3. Specialized: Scroll saws are specialized tools for detailed, curved cuts. They are less versatile than table saws for various woodworking tasks.

Cost

Here are some general cost ranges for both types of saws as of my last knowledge update in September 2021:

Table Saw

1. Portable/Tabletop Table Saw: These are often the most affordable and can range from $150 to $600, with higher-end models and features costing more.

2. Cabinet Table Saw: These are the most expensive and can range from $1,500 to $5,000, with professional-grade models commanding higher prices.

Scroll Saw

1. Entry-Level Scroll Saw: Basic scroll saws suitable for beginners can be found for as low as $100 to $200.

3. High-End Scroll Saw: Professional-grade scroll saws with advanced features and superior build quality can range from $500 to $2,000.

The cost of accessories and blades should also be factored into your budget.

Variable speed

Variable speed in power tools, including saws, refers to adjusting the tool’s operating speed to suit different tasks and materials. Having variable speed control can be advantageous in various situations. Here’s how it applies to saws:

Advantages of Variable Speed in Saws

1. Versatility: Variable speed allows you to adapt the saw’s cutting speed to different materials. For example, when cutting through hardwood, you can reduce the speed to prevent overheating or burning.

2. Precision: Slower speeds can provide better control and accuracy, especially when making intricate or detailed cuts, such as with a scroll saw.

3. Reduced Heat and Friction: Lower speeds generate less heat and friction, extending the life of your saw blades and reducing the risk of material damage.

4. Safety: Variable speed can enhance safety by allowing you to select a speed appropriate for the material and type of cut, reducing the likelihood of kickbacks or accidents.

5. Noise Reduction: In some cases, running a saw at lower speeds may reduce noise levels, which can be beneficial when working in quieter environments or shared spaces.

Applications for Variable Speed:

1. Scroll Saws: Variable speed is crucial for scroll saws, enabling woodworkers to adjust the blade speed for intricate, detailed cuts in various types of wood.

2. Jigsaws: Jigsaws with variable speed settings can be used for different materials and cutting techniques, from straight cuts in wood to curved cuts in metal.

3. Reciprocating Saws: Variable speed control is helpful in reciprocating saws when cutting through various materials like wood, metal, and plastic.

4. Router and Router Tables: Routers often come with variable speed settings, essential for different bit types and wood species.

5. Drill Presses: Some drill presses feature variable speeds for drilling holes in materials of varying hardness.

Precision

Precision in the context of power tools, including saws, refers to the ability to make accurate and exact cuts or operations. Precision is critical for many woodworking and cutting tasks, as it ensures that the final product meets the desired specifications. Here’s how precision is essential in saws:

1. Accuracy: Precision in saws ensures the cuts are accurate and match the intended measurements and angles. This is crucial for creating components that fit together precisely in woodworking projects.

2. Clean Cuts: Precise saws produce clean and smooth cuts with minimal tear-out or splintering. This is especially important for achieving a professional finish in woodworking and minimizing the need for additional sanding or finishing work.

3. Repeatability: Precision tools allow for consistent and repeatable results. This is essential when making multiple cuts or producing identical pieces for assembly.

4. Tight Joints: In woodworking, precise cuts are necessary for creating tight-fitting joints, such as dovetails, mortise and tenon, or finger joints. These joints rely on precision for strength and aesthetics.

5. Intricate Work: For tasks that involve intricate designs, scroll saws are known for their precision. They enable woodworkers to create detailed, intricate cuts and patterns in thin materials.

6. Fine Detailing: Precision is crucial when making fine detailing cuts, such as inlays, engraving, or marquetry. Scroll saws and other fine-detail saws excel in these applications.

7. Miters and Bevels: Precision saws with adjustable angles are essential in tasks requiring precise angles and slopes, such as frame-making.

8. Reduced Waste: Precision cuts minimize material waste. When each cut is accurate, mistakes are less likely to result in wasted material.

Lack of Intricacy

“Lack of intricacy” refers to a limitation in the ability of a particular tool or process to handle highly detailed, intricate, or complex work. In the context of saws, especially table saws, this term implies that these tools must be better suited for making extremely fine, detailed, or curved cuts. Here’s how this limitation applies:

1. Straight Cuts: Table saws are primarily made for straight cuts. They excel at ripping (cutting with the grain) and crosscutting (cutting across the grain) in materials like wood, plywood, and other sheet goods. However, they cannot make curved or intricate cuts.

2. Inability to Follow Complex Outlines: Table saws cannot easily follow intricate or complex patterns or outlines. They are unsuitable for tasks requiring cutting detailed shapes, small interior cutouts, or tight curves.

3. Limited Internal Cuts: Making internal cuts (cuts that start within the material) is challenging with a table saw. It’s often impossible to create openings or shapes within a workpiece using a table saw alone.

4. Not Ideal for Decorative Work: When it comes to decorative woodworking or projects that involve ornate designs and detailed carving, there are better tools than a table saw. In such cases, a scroll saw, or a jigsaw is more appropriate due to their ability to handle intricate work.

5. Safety Concerns: Making intricate cuts on a table saw can be unsafe. The risk of kickback and accidents increases when manipulating small, intricate pieces of material through the table saw blade.

For tasks requiring intricate detailing, curved cuts, or complex patterns, woodworkers typically turn to other tools like:

· Scroll Saws: Scroll saws are explicitly designed for intricate and detailed work. They can make tight curves, follow complex patterns, and are ideal for decorative woodworking and crafts.

· Jigsaws: Jigsaws are versatile tools that can handle curved cuts and intricate shapes. They are suitable for tasks that require more flexibility than a table saw can provide.

· Router with Templates: Routers with templates or guides can be used for precise shaping and detailing work, such as creating decorative edges or inlays.

Straight Cuts Scroll saw vs. table saw

When it comes to making straight cuts, there’s a clear distinction between the capabilities of a scroll saw and a table saw:

Table Saw for Straight Cuts:

· Advantages:

1. Precision: Table saws are known for their precision when making straight cuts. They excel at ripping (cutting with the grain) and crosscutting (cutting across the grain) to produce accurate, clean edges.

2. Efficiency: Table saws are efficient and fast at making straight cuts, particularly in larger pieces of wood or sheet goods like plywood.

3. Repeatable Cuts: They are ideal for consistently making multiple identical straight cuts.

4. Versatility: Table saws can handle various materials, including hardwoods, softwoods, plywood, MDF, and more.

· Disadvantages:

1. Lack of Intricacy: While excellent for straight cuts, table saws are not designed for intricate, detailed, or curved cuts.

2. Safety Concerns: There are safety considerations, as they have exposed blades and a higher risk of kickback.

Scroll Saw for Straight Cuts:

· Advantages:

1. Precision: Scroll saws can make precise straight cuts with the appropriate blade and guide. They are known for their accuracy in intricate work, which can translate to straight cuts.

2. Control: Scroll saws offer excellent control over the cutting process, allowing straight cuts even in thin materials.

3. Safety: They are considered safer for straight cuts due to the enclosed blade and reduced risk of kickback.

4. Quiet Operation: Scroll saws tend to be quieter, which can be advantageous in shared workspaces.

5. Small Size: Scroll saws are compact and portable, making them suitable for smaller workshops.

Disadvantages

1. Slower: Scroll saws are generally slower than table saws when making straight cuts, which can be a drawback for larger projects or production work.

Conclusion

In conclusion, the choice between a scroll saw and a table saw for making straight cuts depends on your specific woodworking requirements:

Table Saw for Straight Cuts:

- · Offers excellent precision and efficiency for straight cuts in various materials.

- · Ideal for rip cuts, crosscuts, and repeated cuts with consistency.

- · Best suited for larger projects and tasks that prioritize straightness and speed.

- · Not designed for intricate, detailed, or curved cuts.

- · Requires greater caution due to exposed blades and a higher risk of kickback.

Scroll Saw for Straight Cuts:

- · Provides precision and control for straight cuts, especially in thin materials.

- · Safer to use due to the enclosed blade and lower risk of kickback.

- · Suitable for intricate work, decorative projects, and tasks where precision is essential.

- · Slower compared to table saws, making it less efficient for large-scale straight cuts.