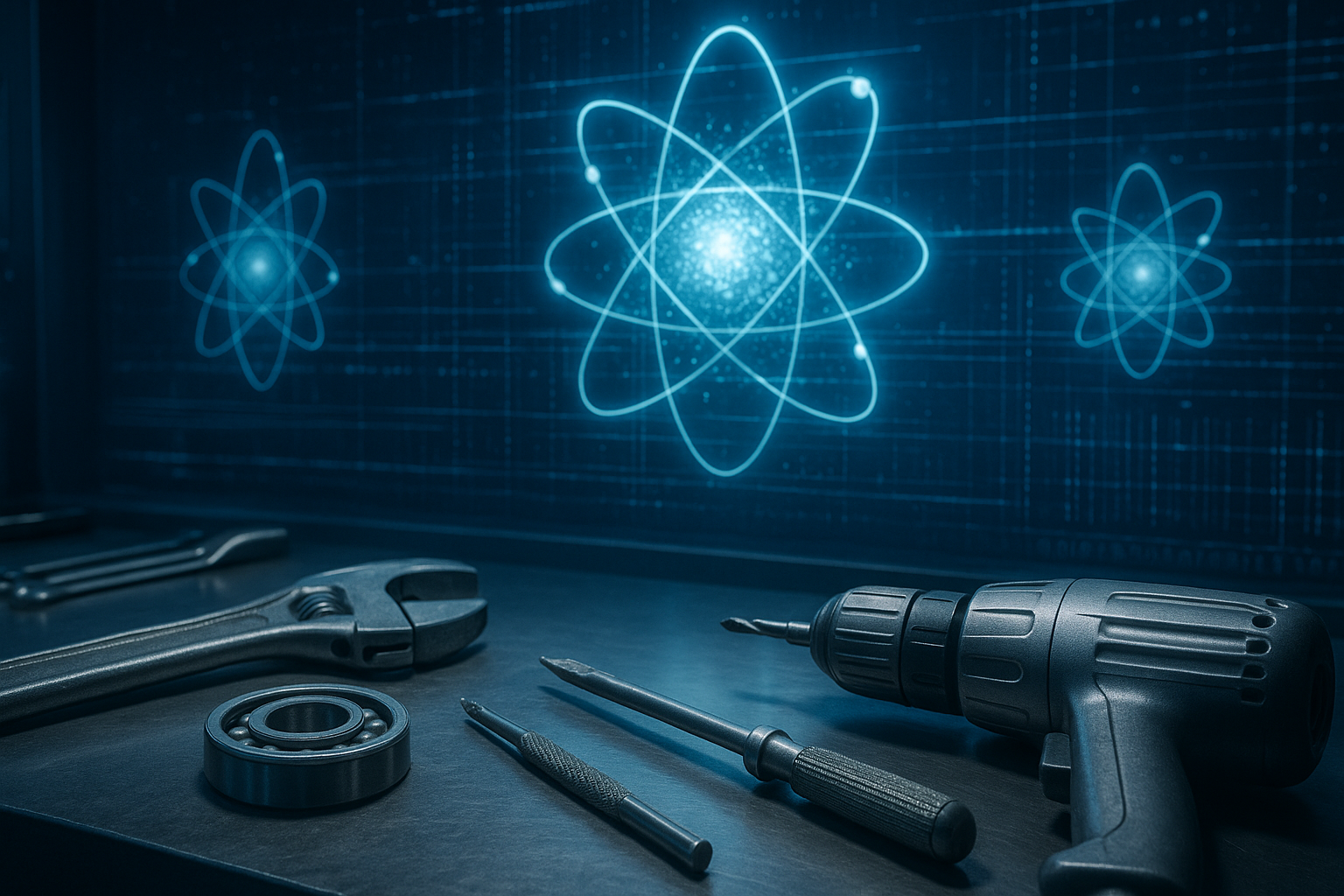

For decades, innovation in the tool industry has been measured in torque, weight, and energy efficiency. But a new kind of power is emerging — one that doesn’t come from batteries or motors, but from math.

Quantum computing, once confined to physics labs and theoretical models, is beginning to influence how tools are designed, optimized, and even manufactured.

This isn’t science fiction. It’s the next step in the evolution of craftsmanship — where material design, energy efficiency, and mechanical precision are being reimagined at the quantum level.

What Quantum Computing Brings to Manufacturing

Traditional computers analyze one possibility at a time.

Quantum computers, however, can evaluate millions of outcomes simultaneously — an ability that makes them particularly effective at solving optimization problems.

For tool manufacturers, this means faster, smarter design.

Quantum algorithms can test countless combinations of materials, geometries, and stress tolerances in seconds — identifying ideal configurations for strength, durability, and weight.

According to IBM Research, early experiments using quantum simulations for industrial materials have already revealed new alloy structures that traditional computing models couldn’t predict.

This capability aligns closely with the generative design principles already transforming engineering software, as seen in How AI Is Reinventing the Future of Tools and Workshops — but now operating on an exponentially deeper scale.

Smarter Materials Through Quantum Simulation

Quantum computers excel at understanding atomic interactions — a critical factor in developing next-generation materials.

By simulating matter at the molecular level, researchers can discover compounds with higher conductivity, lighter weight, and superior heat resistance.

For example, tool components designed using quantum-based models could:

- Dissipate heat more effectively in power tools.

- Increase cutting efficiency without extra energy use.

- Improve the charge density and lifespan of lithium-based batteries.

Projects led by Google Quantum AI and Rigetti Computing are already exploring these applications, with results that could reshape how both industrial and consumer tools are built.

This scientific approach could directly enhance technologies like tabless batteries — optimizing how electrons move through redesigned energy cells.

Quantum-Optimized Design

Beyond materials, quantum computing is also influencing how tools are engineered.

Instead of relying solely on trial-and-error prototyping, developers can use quantum algorithms to identify design flaws before production even begins.

This method allows manufacturers to balance strength, flexibility, and cost at unprecedented precision — much like AI-driven modeling systems discussed in Inside the Smart Workshop: Connected Tools That Think for You.

The outcome: tools that perform better, weigh less, and require fewer resources to produce.

Energy and Efficiency at the Quantum Scale

Power consumption remains one of the greatest challenges in modern workshops.

Quantum-assisted energy modeling could help optimize how tools draw and store energy, particularly in battery-based systems.

By simulating millions of micro-adjustments in energy flow, quantum computing can predict the most efficient power usage patterns — ensuring cleaner, longer operation times and cooler systems.

The implications reach far beyond performance.

Smarter energy flow supports the sustainability goals discussed in Sustainable Power: How Tool Brands Are Going Carbon Neutral — making efficiency not only a technological advantage but an environmental one.

Challenges Ahead

Despite its potential, quantum computing in tool design is still in its infancy.

Quantum processors are expensive, require extreme cooling conditions, and remain limited in the number of “qubits” they can process.

But progress is rapid.

Industry leaders predict that within the next five to seven years, hybrid systems — where quantum computers work alongside classical AI systems — will become practical for commercial use in design and manufacturing.

When that happens, even small-scale toolmakers could gain access to simulations and optimizations that were once limited to aerospace or energy research.

A Glimpse Into the Quantum Workshop

The concept of a “quantum workshop” may sound abstract, but its foundation is already visible.

AI, IoT, and predictive modeling have laid the groundwork for tools that think, adapt, and self-optimize.

Quantum computing will take that one step further — helping creators understand why their designs work, not just how.

The next generation of tools won’t just be faster or smarter; they’ll be mathematically perfect.

And the workshop, once a place of trial and error, could soon become a laboratory of precision powered by quantum intelligence.