In mechanical engineering and metalworking, precision and efficiency are paramount. One tool that plays an essential role in achieving these goals is the power hacksaw.

If you’re new to this field, you might wonder, “What is a power hacksaw, and how does it work?” This article will delve into the world of power hacksaws, unravelling their inner workings, applications, and advantages.

The Power behind Power Hacksaws

A power hacksaw is a specialized cutting tool used in various industries to slice through metal and plastic. Unlike its manual counterpart, the power hacksaw relies on automated mechanisms, making it a favored choice for repetitive and consistent cutting tasks.

How Does It Work?

At its core, a power hacksaw consists of a sturdy frame that holds the workpiece and the cutting blade. This reciprocating motion, combined with the sharpness of the blade, enables the power hacksaw to make clean and accurate cuts through even the most rigid materials.

How Does a Power Hacksaw Work?

In the world of mechanical marvels, the power hacksaw is a testament to precision engineering and efficient metal cutting. This formidable tool has been a staple in industries for decades, making the seemingly impossible task of slicing through solid metal seem like child’s play.

Understanding the Basics

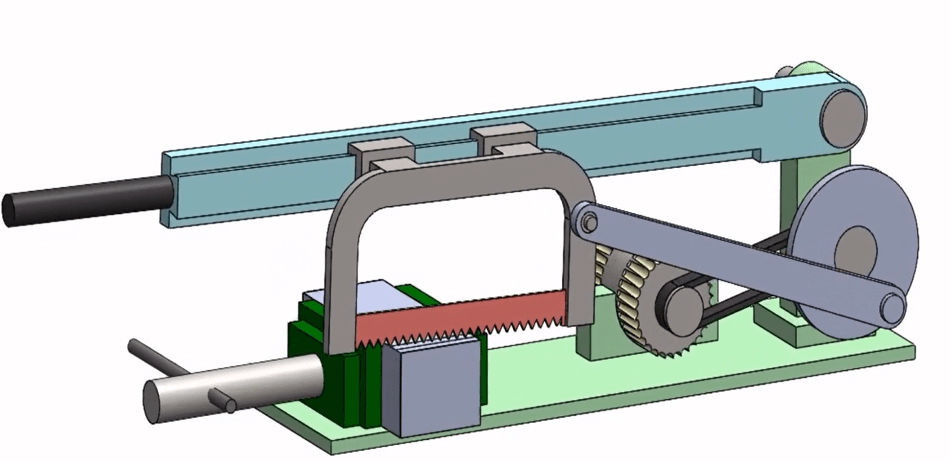

At its core, a power hacksaw is a machine that cuts through metal using a reciprocating blade. It operates on the fundamental principles of mechanical advantage and precision. The primary components of a power hacksaw include:

Frame: The sturdy frame of the machine provides the foundation for the entire system. It keeps all the components in alignment and ensures stability during operation.

Motor: The heart of the power hacksaw, the motor, provides the necessary power to drive the cutting action. Most power hacksaws are equipped with electric motors for consistent and reliable performance.

Blade: The blade is the cutting tool itself. It’s typically made of high-speed steel or tungsten carbide, known for its durability and ability to maintain sharpness over time.

Vise: The vise holds the workpiece securely in place during cutting. It ensures the metal remains stationary, allowing for precise and accurate cuts.

The Cutting Process

Now, let’s dive into the fascinating process of how a power hacksaw works:

Clamping the Workpiece: The first step in using a power hacksaw is securing the metal workpiece in the vise. This ensures that the material remains stationary and stable during cutting.

Setting the Blade: The operator adjusts the blade’s position according to the desired cut length and angle. This is crucial for achieving accurate results.

Activating the Motor: The electric motor is switched on once the workpiece and blade are set. This motor drives the blade in a back-and-forth motion.

Cutting Action: As the blade moves back and forth, it makes contact with the metal. The teeth on the blade gradually cut into the material, producing precise and even cuts.

Coolant System: Many power hacksaws have a coolant system to prevent overheating. This system sprays a cooling lubricant onto the blade and workpiece, prolonging the blade’s life and maintaining cutting efficiency.

Automatic Shutoff: Many modern power hacksaws feature an automatic shutoff mechanism once the cut is complete. This ensures the machine stops once the cut is finished, enhancing safety and convenience.

Applications of Power Hacksaws

Power hacksaws find applications in various industries, including:

Metal Fabrication: They are indispensable in cutting and shaping metal parts for various structures and machinery.

Automotive Industry: Power hacksaws are used to cut metal components in the production of automobiles.

Shipbuilding: These machines aid in the construction of ships by cutting through thick metal plates.

Construction: Power hacksaws create precise cuts in steel beams and other construction materials.

Repair and Maintenance: They are crucial in repairing and maintaining heavy machinery and equipment.

Power Hacksaws

A power hacksaw is a mechanical cutting device designed to cut through metal materials cleanly. It operates on the principle of reciprocating motion, where a blade moves back and forth, slicing through the workpiece with precision.

Power hacksaws are widely used in manufacturing, construction, and metal fabrication industries due to their ability to make accurate and efficient cuts.

Types of Power Hacksaws

Hydraulic Power Hacksaws

Hydraulic power hacksaws are renowned for their robustness and ability to handle heavy-duty cutting tasks. They utilize hydraulic pressure to control the cutting process, ensuring a consistent and powerful force is applied to the blade. This type of power hacksaw is ideal for cutting thick and dense materials, making it a favorite in industrial settings.

Electric Power Hacksaws

Electric power hacksaws are known for their versatility and ease of use. These hacksaws are powered by electricity and come in various sizes to accommodate different workpiece dimensions. They are suitable for both small-scale operations and larger projects, making them a popular choice for workshops and metalworking shops.

Pneumatic Power Hacksaws

Pneumatic power hacksaws rely on compressed air to drive the cutting process. These hacksaws offer a high degree of precision. They are often used in applications where clean and accurate cuts are crucial. Industries such as aerospace and automotive manufacturing frequently utilize pneumatic power hacksaws for reliability and efficiency.

Mechanical Power Hacksaws

Mechanical power hacksaws are the traditional workhorses of metal cutting. They are driven by a mechanical system that imparts motion to the blade. While they may not offer the same level of automation as hydraulic or electric hacksaws, they remain a dependable choice for tasks that require precision and control.

Key Features of Power Hacksaws

Understanding the key features of power hacksaws is essential for selecting the right tool for your specific needs. Let’s explore some of these features in detail:

Blade Speed Control

Most modern power hacksaws come equipped with adjustable blade speed controls. This feature allows operators to optimize cutting speed based on the processed material. A slower blade speed is preferred for harder metals to ensure clean and accurate cuts. At the same time, softer materials may require a higher blade speed for efficiency.

Cutting Capacity

Power hacksaws are available in various sizes, each with its cutting capacity. It’s essential to choose a hacksaw that can comfortably accommodate the dimensions of your workpieces. Oversized hacksaws can lead to inefficient cutting, while undersized ones may not handle more extensive materials adequately.

Blade Tensioning

Proper blade tensioning is crucial for achieving precise cuts and prolonging blade life. Power hacksaws often feature blade tensioning mechanisms that ensure the blade remains taut during operation. This minimizes blade deflection and enhances cutting accuracy.

Automatic Shutoff

Many modern power hacksaws are equipped with automatic shutoff mechanisms, enhancing safety and reducing the risk of accidents. These systems can detect unusual operating conditions and shut down the machine to prevent damage or injury.

Maintenance and Care of Power Hacksaw

In today’s industrial landscape, power hacksaws have become indispensable tools for cutting through various materials efficiently. Whether you’re working in a metal fabrication workshop or a construction site, the power hacksaw is a trusty companion.

Regular Inspection and Cleaning

To guarantee optimal performance, conducting regular inspections and cleaning sessions for your power hacksaw is essential. Here’s how you can go about it:

1. Inspection

Start by inspecting the entire machine meticulously. Look for wear and tear, loose bolts, or damaged components. Pay special attention to the blade, as it is the heart of your power hacksaw.

2. Cleaning

After the inspection

- Clean all the exposed parts of your hacksaw.

- Remove accumulated dust, debris, and metal shavings using a brush and compressed air.

- Ensure the cleanliness of the blade, as any residue can affect the quality of your cuts.

II. Blade Maintenance

The blade is the workhorse of your power hacksaw, and its maintenance is critical for top-notch performance. Here’s how you can keep it in pristine condition:

1. Blade Tension

Check the tension of the blade regularly. An improperly tensioned blade can result in poor cutting performance. Refer to your hacksaw’s manual for specific tensioning instructions.

2. Blade Lubrication

Proper lubrication is essential to prevent overheating and premature wear of the blade. Apply a suitable cutting fluid or lubricant to the blade before each operation. This not only enhances cutting efficiency but also extends the blade’s lifespan.

3. Blade Replacement

Blades don’t last forever. It’s time for a replacement when you notice signs of dullness or reduced cutting efficiency. Always have spare blades on hand to avoid downtime.

III. Alignment and Calibration

Ensuring that your power hacksaw is correctly aligned and calibrated is paramount for precise cuts. Here’s what you should focus on:

1. Blade Alignment

Check that the blade is aligned parallel to the workpiece. Any misalignment can lead to irregular cuts and unnecessary material wastage.

2. Blade Height

Adjust the blade’s height according to the material you’re cutting. This ensures the hacksaw exerts the correct pressure, resulting in cleaner cuts.

IV. Safety Precautions

Safety should never be compromised in any industrial setting. Ensure you and your team follow these safety precautions:

1. Machine Safety

Familiarize yourself with the power hacksaw’s emergency stop mechanism and safety features. Ensure they are functioning correctly at all times.

V. Storage and Environmental Considerations

Proper storage and environmental conditions are often overlooked but can significantly impact your power hacksaw’s lifespan. Here’s what you need to keep in mind:

1. Storage

Store your power hacksaw in a clean, dry, and well-ventilated area when not in use. Cover it to prevent dust and moisture accumulation.

VI. Regular Maintenance Schedule

Create a maintenance schedule for your power hacksaw, outlining when each task should be performed. This ensures everything is noticed and your machine consistently delivers optimal results.

Safety Precautions of Power Hacksaw

In metalworking and fabrication, power hacksaws are invaluable tools that facilitate precise and efficient cutting of various materials. These robust machines are used in industrial settings, construction sites, and workshops to make clean and accurate cuts.

While they undoubtedly offer numerous advantages, it’s crucial to remember that they can be potentially hazardous if not operated with care and attention. Your safety and that of those around you should always be the top priority when working with such powerful equipment.

Understanding the Power Hacksaw

Before we dive into the safety precautions, let’s briefly understand what a power hacksaw is and how it operates. A power hacksaw is a mechanical cutting device equipped with a reciprocating blade.

It is designed to cut through various materials, such as metal, plastic, and wood, with remarkable precision. The machine’s blade moves back and forth, continuously cutting as it slices through the material.

Safety Precautions for Power Hacksaw Operation

1. Read the Manual Thoroughly

One of the most fundamental safety measures when using machinery, including power hacksaws, is reading and understanding the manufacturer’s manual. The manual provides valuable information regarding the machine’s operation, maintenance, and safety guidelines. Take the time to familiarize yourself with the manual to ensure you know all the machine’s features and potential risks.

2. Wear Appropriate Personal Protective Equipment (PPE)

Before operating a power hacksaw, ensure that you are wearing the necessary personal protective equipment.

3. Inspect the Machine

Check for loose bolts, damaged parts, or any abnormalities that may compromise its safety or functionality. If you discover any issues, only use the machine once it has been repaired and deemed safe by a qualified technician.

4. Secure the Workpiece

Properly secure the workpiece in the machine’s vise or clamp. The workpiece should be stable and firmly held to prevent it from shifting during cutting. This stability is crucial for achieving precise cuts and avoiding accidents.

5. Adjust the Cutting Speed

Power hacksaws offer the flexibility to adjust the cutting speed according to the cut material. Ensure you have selected the appropriate cutting speed for the specific material to achieve optimal results. Cutting at the wrong speed can lead to blade breakage or uneven cuts.

6. Use the Correct Blade

Selecting the right blade for your cutting task is vital. Different blades are designed to cut specific materials, so make sure you use the appropriate blade for the job. Using the correct blade can result in efficient cutting and increased safety risks.

7. Maintain a Safe Distance

While the power hacksaw is operating, maintain a safe distance from the machine. Stand clear of the cutting path to avoid being hit by any debris that may be ejected during the cutting process.

8. Avoid Loose Clothing and Jewelry

Before using the power hacksaw, ensure you are not wearing loose clothing, jewelry, or any accessories. Loose items can pose a severe safety hazard.

9. Keep the Workspace Clean

Maintain a clean and organized workspace. Remove any clutter or obstructions that impede movement or interfere with the power hacksaw’s operation. A tidy workspace reduces the risk of accidents.

10. Emergency Stop

Familiarize yourself with the location of the machine’s emergency stop button. In case of an unexpected issue or emergency, you should be able to stop the machine to prevent accidents or injuries quickly.

Advantages of Using a Power Hacksaw

Using a power hacksaw offers several advantages in various industrial and metalworking applications. Here are some of the key benefits:

Efficiency: Power hacksaws are designed to cut through metal quickly and efficiently. They can make precise and repetitive cuts with minimal effort, saving time and labor compared to manual hacksaws.

Accuracy: Power hacksaws provide consistent and accurate cuts, ensuring each material is cut to the desired dimensions. This is crucial in applications where precision is essential.

Reduced Fatigue: Unlike manual hacksaws that require physical exertion and can lead to operator fatigue, power hacksaws are motor-driven. This reduces the physical strain on operators, allowing them to work for more extended periods without tiring as quickly.

Versatility: Power hacksaws can cut a wide range of materials, including metals, plastics, and wood, making them versatile tools in various industries, such as metalworking, fabrication, and construction.

Uniformity: Power hacksaws provide uniform cuts across multiple workpieces, ensuring that all parts are consistent in size and shape. This uniformity is essential for assembly and manufacturing processes.

Automation: Some power hacksaws can be programmed to make repetitive cuts automatically, which is particularly beneficial for high-volume production and mass manufacturing. This reduces the need for constant operator intervention.

Safety: Power hacksaws have safety features, such as blade guards and emergency shutoff mechanisms, to protect operators.

Clean Cuts: Power hacksaws typically produce cleaner cuts with minimal burrs or rough edges compared to manual hacksaws. This reduces the need for additional finishing work and improves the overall quality of the cut.

Increased Productivity: Power hacksaws can increase productivity in a workshop or manufacturing setting due to their speed and efficiency.

Cost-Effective: While power hacksaws require an initial investment, they can provide long-term cost savings through increased efficiency and reduced labor costs. They also tend to have a longer lifespan than manual hacksaws when adequately maintained.

Conclusion

Power saws are indispensable for efficiency, precision, and versatility in cutting various materials. Their ability to reduce fatigue, ensure safety, and enhance productivity makes them essential assets in the construction and manufacturing industries.

Whether for occasional DIY projects or large-scale production, power saws are vital in simplifying cutting tasks and delivering high-quality results.