Have you ever wondered what is a step drill bit used for? If you’ve ever tackled a drilling project that involves creating holes of different sizes, you’re in for a treat! Step drill bits are versatile tools that make drilling holes of varying diameters a breeze.

This article will explore the world of step drill bits and highlight their primary purpose. So, if you’re curious about what tasks these handy tools are designed for, read on to find out!

Understanding Step Drill Bits

Step drill bits, also known as step cone bits or units, are specialized drilling tools designed for creating holes of various diameters in materials such as metal, wood, plastic, and other similar substances.

These bits have a unique stepped design with multiple cutting edges of increasing diameter. Understanding step drill bits involves knowing their construction, advantages, and typical applications:

Construction:

- Conical Shape: Step drill bits have a conical or tapered shape, with a sharp tip toward one side and a knife at the other.

- Multiple Cutting Edges: The stepped design features multiple cutting edges arranged in a staircase-like fashion, each with a different diameter.

- Flutes: Step bits usually have two or more flutes that spiral around the bit’s body, allowing for efficient chip evacuation during drilling.

Advantages:

- Versatility: Step drill bits can create holes of various sizes without changing bits. This versatility makes them convenient for users requiring holes of different diameters.

- Smooth Hole Edges: The stepped design produces clean, smooth holes with minimal burring or deformation, crucial for applications like installing electrical conduits or plastic grommets.

- Self-Starting: Step bits are self-centering and self-starting, meaning they don’t require a pilot hole or center punch. This feature ensures accurate hole placement and prevents wandering during drilling.

- Reduced Tool Changes: Since a single-step bit can replace multiple traditional bits, users can complete projects more efficiently, reducing the need for frequent bit changes.

- Speed and Precision: Step bits are typically designed for high-speed drills and provide precise control when enlarging or creating holes.

Common Applications:

- Metalworking: Step drill bits are often used in metalworking applications to create holes in materials like steel, aluminum, brass, and copper. They are handy for sheet metal fabrication.

- Woodworking: Woodworkers use step bits to create holes in wooden surfaces for cable routing, doweling, or other purposes.

- Plastic: Step bits can make clean holes in plastic materials without causing excessive melting or chipping.

- Electrical Work: Electricians use step bits to drill holes for conduit fittings, junction boxes, and cable pass-throughs.

- Plumbing: Step bits are suitable for drilling holes in plastic pipes, ensuring a snug fit for pipe fittings.

- Automotive: Step bits are handy for drilling holes in automotive body panels, especially for installing accessories or creating openings for wires and hoses.

Typical Applications of Step Drill Bits

Step drill bits, also known as step cones or units, are versatile cutting tools with multiple stepped diameters. They are instrumental in various applications where you must drill holes of different sizes without changing the bit.

Here are some typical applications of step drill bits:

- Sheet Metal: Step drill bits are widely used in sheet metal fabrication and HVAC (heating, ventilation, and air conditioning) installations. They can create clean, precise holes in thin metal sheets for fastening screws, bolts, or rivets.

- Electrical Conduit Installation: Electricians often use step drill bits to create holes in metal electrical enclosures, junction boxes, and conduits for running wires and cables. The ability to step through different hole sizes makes them highly efficient.

- Automotive Repair: Step drill bits are useful in automotive repair and customization. Mechanics and auto enthusiasts employ them to create holes for installing accessories like antennas, lights, and brackets on metal surfaces.

- Plumbing: Plumbers use step drill bits to create holes in metal pipes, especially when installing water lines, conduits, or drain pipes. The step design allows them to drill holes of varying sizes to accommodate different pipe fittings.

- Aircraft Maintenance: In the aviation industry, step drill bits are used for drilling holes in aircraft panels, frames, and components. The ability to drill precise holes in thin and lightweight materials is essential for repairs and modifications.

- Woodworking: While primarily designed for metal, step drill bits can also create holes in wooden boards or composite materials. They are helpful when you need to countersink screws or make stepped holes for dowels.

- General DIY and Home Improvement: Step drill bits find applications in various DIY projects and home improvement tasks. They are handy for creating holes in metal, plastic, and wood when working on projects like building furniture, installing shelves, or crafting.

- Cable and Wire Management: In data centers and server rooms, step drill bits are used to create precise holes in metal racks and enclosures for cable management solutions like cable grommets or routing cables.

- Metalworking: Machinists and metalworkers may use step drill bits for precision hole-making in metal parts and components. The step design allows for efficient drilling without frequent bit changes.

- Automotive Panel Restoration: Restoring classic cars often involves drilling holes for body panel repairs and modifications. Step drill bits can create the necessary holes with ease.

- Custom Fabrication: In custom fabrication and metalworking shops, step drill bits are employed to create holes in various materials for specialized projects, such as custom brackets and mounting solutions.

Step drill bits are prized for their versatility and time-saving capabilities, making them valuable tools in numerous industries and applications where holes of different sizes and precise dimensions are required. Their ability to streamline hole-making processes contributes to greater efficiency and accuracy in various projects.

Advantages of Step Drill Bits

Step drill bits, also known as step cone bits or units, offer advantages that make them indispensable tools for various drilling applications. Their essential strength lies in their capacity to drill multiple hole sizes with a single bit, with each step on the bit corresponding to a different hole diameter. This eliminates the need for frequent bit changes, saving valuable time and simplifying the drilling process.

Versatility is another hallmark, as step drill bits can tackle various materials, including metal, plastic, wood, and composites, making them adaptable to diverse industries. These bits produce clean and precise holes with smooth edges, reducing the need for extensive finishing work.

Moreover, the stepped design minimizes material waste, which is especially crucial when working with costly or limited-supply materials. Their efficiency, ease of use, and compactness make them suitable for professionals and DIY enthusiasts.

Step drill bits are self-centering, aiding in accurate hole placement, and their durability, particularly in high-quality variants made from materials like high-speed steel (HSS) or cobalt alloy, ensures a long service life.

Despite the initial investment, step drill bits prove cost-effective in the long run due to reduced tool changes and material waste. They are invaluable tools in metalworking, woodworking, electrical, plumbing, and many DIY projects, where efficiency and precision are paramount.

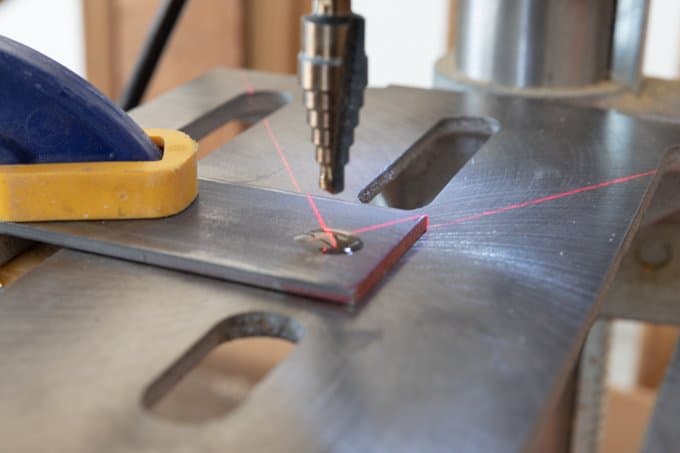

How to Use a Step Drill Bit?

Using a step drill bit is relatively straightforward, and it’s a versatile tool that allows you to drill holes of varying sizes with a single bit. Here’s a step-by-step guide on how to use a step drill bit effectively:

Select the Right Bit

Choose the appropriate step drill bit for your specific application and material. Consider the hole size you need to create and the thickness of the material.

Secure the Workpiece

Clamp or secure the workpiece firmly in place to prevent it from moving during drilling. This ensures stability and accuracy.

Mark the Hole Location

Mark the center of the hole you want to drill using a center punch or a sharp awl. This indentation will help the drill bit start in the desired location and prevent it from wandering.

Set the Drill Speed

If you use a power drill, set it to the correct speed for the material you are drilling. Refer to the drill bit manufacturer’s recommendations for the appropriate rate.

Begin Drilling

Place the tip of the step drill bit on the marked indentation, ensuring it is centered and perpendicular to the surface. Apply steady and even pressure to the drill as you start drilling. It’s crucial to keep the training straight to avoid creating off-center holes.

Drill in Steps

Start with the first step on the bit, which is the smallest diameter, and drill until you reach the desired depth for that size hole. Be cautious not to force the drill; let it cut at its own pace. The stepped design of the bit will guide you to the correct depth for each step.

Progress to Larger Steps

Once you’ve reached the desired depth for the first step, slowly lift the drill bit out of the hole while the drill is still running. Move on to the next significant step on the bit, align it with the spot, and resume drilling. Repeat this process for each step on the bit until you reach the final hole diameter you need.

Clean as You Go

Periodically withdraw the bit from the hole to clear away chips and debris. This will help maintain clean, precise drilling and prevent overheating.

Finish the Hole

If you require a completely clean and burr-free hole, you may need to use a deburring tool or a countersink bit to eliminate any sharp edges or burrs left by the step drill bit.

Inspect and Test

Once you’ve completed the hole, inspect it for accuracy and quality. Test-fit any components or fasteners to ensure they fit correctly in the hole.

Tips for Using Step Drill Bits Effectively

Using step drill bits effectively requires proper technique and attention to detail to achieve clean and accurate holes. Here are some tips for using step drill bits effectively:

Select the Right Bit

Choose the appropriate step drill bit for your specific application and material. Consider the size of the hole you need and the thickness of the material.

Secure the Workpiece

Clamp or secure the workpiece firmly in place to prevent it from moving during drilling. This ensures stability and accuracy.

Mark Hole Locations

Use a center punch or a sharp awl to mark the center of each hole you plan to drill. These indentations will help the drill bit start in the desired location and prevent wandering.

Set the Drill Speed

If you’re using a power drill, set it to the correct speed for the material you’re drilling. Consult the drill bit manufacturer’s recommendations for the appropriate rate.

Start Slowly

Begin drilling slowly to create a pilot hole using the first step on the bit. This helps ensure accurate hole placement.

Apply Steady Pressure

Apply steady and even pressure as you drill. Avoid forcing the drill bit; let it cut at its own pace. Maintaining a straight and perpendicular angle is essential for accurate holes.

Clear Chips Regularly

Periodically withdraw the bit from the hole to clear away chips and debris. This prevents clogging and overheating and maintains clean and efficient drilling.

Progress to Larger Steps

Once drilled to the desired depth with the first step, slowly lift the dull tool into a healthier place while the drill runs. Move on to the next significant step on the bit, align it with the spot, and resume drilling. Repeat this process for each step on the bit until you reach the final hole diameter.

Inspect and Test

After completing the hole, inspect it for accuracy and quality. Test-fit any components or fasteners to ensure they fit correctly in the hole.

Deburring

If necessary, use a deburring tool or countersink bit to remove any sharp edges or burrs left by the step drill bit. This is important for achieving a clean and finished look.

Coolant or Lubricant

When drilling harder metals, consider cutting fluid or lubricant to reduce friction and heat. This can prolong the life of the step drill bit and ensure smoother drilling.

Practice on Scrap Material

If you’re new to using step drill bits or need to achieve precise results, practice on scrap material first to familiarize yourself with the tool and technique.

Following these tips, you can use step drill bits effectively to create clean, accurate holes in various materials and achieve professional-quality results in your drilling projects.

Maintenance and Care

Proper maintenance and care of your step drill bit are essential to ensure its longevity and continued effectiveness. Here are some maintenance and care tips to keep your step drill bit in excellent condition:

Clean After Use

After each use, clean the step drill bit thoroughly to remove metal shavings, debris, and any cutting fluid or lubricant residue. Use a wire brush, compressed air, or a dedicated drill bit cleaning tool to remove these materials from the flutes and cutting edges.

Inspect for Damage

Regularly inspect the step drill bit for signs of wear, damage, or dullness. Look for chipped or broken cutting edges, worn flutes, or bent shafts. Damaged or dull bits should be replaced or sharpened promptly.

Sharpen When Necessary

Dull step drill bits can lead to inefficient drilling and overheating. Sharpen them using a suitable drill bit sharpener or a bench grinder. Follow the manufacturer’s instructions or seek professional sharpening services for the best results.

Proper Storage

Store your step drill bits in a protective case or organizer to prevent damage and keep them organized. Avoid tossing them into a toolbox where they can collide with other tools and become damaged.

Rust Prevention

To prevent rust, apply a thin coat of rust inhibitor or light oil to your step drill bits, particularly if they are not coated. Store them in a dry place to minimize exposure to moisture.

Use the Right Speed and Pressure

Use the appropriate drill speed and apply steady but not excessive pressure. Too much stress can cause overheating and premature wear, while too little can result in inefficient drilling.

Use Cutting Fluid

When drilling metals, significantly more complex alloys, and stainless steel, use cutting fluid or lubricant to reduce friction and heat. This helps extend the life of your step drill bit and provides smoother drilling.

Match Bit to Material

Use the correct type of step drill bit for the specific material you are drilling. Different materials have varying hardness levels, and using the wrong bit can lead to reduced bit life and poor results.

Rotate Bits

To distribute wear evenly, rotate and flip your step drill bits periodically if they have multiple cutting edges. This practice helps maintain sharpness and prolongs bit life.

Replace Worn Bits

When a step drill bit becomes too worn, significantly if it cannot be effectively sharpened, replace it promptly. Continuing to use a severely worn bit can result in subpar drilling results and potential damage to your materials or equipment.

Conclusion

A step drill bit is a versatile and practical tool used in various applications across industries and DIY projects. Its unique design allows it to create multiple hole sizes without frequent bit changes, making it a time-saving and cost-effective solution.

Whether used in metalworking, woodworking, plumbing, or other tasks, the step drill bit’s ability to produce clean, accurate holes of different diameters makes it an essential addition to any toolbox. Understanding its functions and proper usage can significantly enhance efficiency and precision when working on projects requiring hole drilling.