In the ever-evolving world of construction and DIY projects, reciprocating saws are indispensable, providing unmatched versatility and precision. Whether you’re a seasoned professional or a passionate DIY enthusiast, understanding the intricate details of these powerful cutting devices is crucial. One of the most pressing questions is, “Are reciprocating saw blades universal?”

In this comprehensive guide, we delve deep into the world of reciprocating saws to explore this question, providing you with the insights you need to make informed decisions for your next cutting task.

Are Reciprocating Saw Blades Interchangeable with Other Saws?

Reciprocating saws are powerful cutting tools in various applications, from construction and demolition to plumbing and DIY projects. They are renowned for their versatility and ability to cut through a wide range of materials, largely thanks to the blades they use. These blades’ unique designs and features are tailored to specific cutting tasks.

While reciprocating saw blades vary in terms of length, material, and tooth design, there is a common factor that plays a pivotal role in interchangeability: the shank design.

Universal Shank Design

Many reciprocating saw blades are designed with a universal shank. This universal shank is intended to fit most reciprocating saws, regardless of the brand. It typically features a twist-and-lock mechanism, allowing easy and secure attachment to the saw.

This universal shank design has become a standard in the industry, allowing users to switch between blades without the need for brand-specific attachments. It’s a significant advancement that enhances the user experience and offers flexibility regarding blade selection.

The Key Consideration: Blade Length and Material

While the universal shank design ensures compatibility regarding attachment, it’s essential to remember that not all reciprocating saw blades are created equal. The key considerations when selecting a knife are its length and material.

What Are the Variations of Reciprocating Saw Blades?

Reciprocating saw blades come in various configurations, each tailored to specific cutting tasks. These variations allow users to achieve precision and efficiency when working with different materials and applications. Let’s explore the critical interpretations of reciprocating saw blades:

Blade Length:

Short Blades: Typically range from 3 to 6 inches in length. These blades are ideal for tasks that require control and precision in tight spaces or for making plunge cuts.

Medium Blades: Range from 6 to 8 inches in length. They balance reach and control, making them versatile for various cutting tasks.

Long Blades: Can extend from 9 to 12 inches. These longer blades are suited for tasks requiring extended reach, such as cutting through pipes or thick materials.

Blade Material:

High-Carbon Steel Blades: These blades are suitable for cutting wood, plastic, and non-metallic materials. They are affordable and work well for general-purpose cutting.

Bi-Metal Blades: Made from two different types of steel, typically high-speed steel teeth welded onto a high-carbon steel body. Bi-metal blades are versatile and can cut through wood, metal, plastic, and even nails. They are a popular choice for demolition work.

Carbide-Tipped Blades: These are heavy-duty blades for cutting through rigid materials like concrete, brick, and masonry. The carbide tips provide exceptional durability and longevity.

Tooth Design:

Variable Teeth (or Wavy Teeth): Variable tooth blades have irregularly spaced teeth, which reduce vibration and make smoother cuts. They are excellent for cutting metal and pipes.

Pruning Blades: These blades have large, widely spaced teeth designed for cutting through tree branches and other vegetation. They are commonly used for landscaping and gardening.

Demolition Blades: Featuring a rugged tooth design, demolition blades are ideal for heavy-duty tasks like tearing down walls and cutting through nails, wood, and metal.

Teeth Per Inch (TPI):

Low TPI: Blades with fewer teeth per inch are designed for faster, rougher cuts in materials like wood. They excel at quickly removing material.

Medium TPI: These blades provide a balance between speed and precision. They are suitable for cutting materials like plastics and some metals.

High TPI: Blades with more teeth per inch are ideal for making smoother and more precise cuts in metal and thin materials.

Specialty Blades:

Flush-Cut Blades: These blades have a unique design that allows for flush cutting, making them perfect for cutting protruding pipes or nails.

Scroll Blades: Designed for intricate and curved cuts, scroll blades are commonly used in woodworking and crafts.

Tile Blades: Featuring a carbide grit edge, tile blades are designed to cut through ceramic, porcelain, and other tile materials.

Reciprocating Saw Blade Sets:

Some manufacturers offer sets of reciprocating saw blades that include various blade types, allowing users to tackle a wide range of tasks without needing individual purchases.

Are Reciprocating Saw Blades Universal for Metal?

Reciprocating saw blades are highly versatile tools, but when cutting metal, you must consider the type of reciprocating saw blade you use. While many reciprocating saw blades are designed to cut through various materials, including metal, there are essential variations to keep in mind:

Blade Material:

Bi-Metal Blades: Bi-metal reciprocating saw blades are specifically engineered to excel in cutting through metal. They feature a combination of high-speed steel teeth and a flexible high-carbon steel body.

This design provides both durability and the ability to withstand metal-cutting demands. Bi-metal blades are the go-to for cutting through metal pipes, rods, and sheets.

Tooth Design and TPI:

Variable Tooth Blades: Blades with irregular or wavy tooth designs are ideal for metal cutting. These blades have irregularly spaced teeth that reduce vibrations and make smoother cuts in metal. The tooth design helps prevent the edge from getting stuck or overheating while cutting through various types of metal.

High TPI Blades: Blades with more teeth per inch (TPI) are well-suited for cutting thin metal materials. They provide cleaner and more precise cuts in sheet metal, aluminum, and other metals.

Blade Length:

The choice of blade length depends on the thickness and accessibility of the metal you intend to cut. Longer blades are beneficial for cutting through thicker metal. In comparison, shorter blades offer more control and are suitable for thinner materials.

How Do You Choose a Reciprocating Saw Blade?

Choosing the right reciprocating saw blade is crucial for achieving efficient and precise cutting results. To select the most appropriate blade for your specific task, follow these steps:

Identify Your Cutting Material:

Determine the type of material you’ll be cutting. Reciprocating saw blades are designed for various materials, including wood, metal, plastic, and masonry. Knowing your fabric is the first step in choosing the right edge.

Consider Material Thickness:

Assess the thickness of the material. Thicker materials may require longer blades for adequate reach and cutting depth.

Understand Blade Materials:

- Familiarize yourself with the different blade materials:

- Bi-Metal Blades: Versatile and suitable for cutting wood, metal, and plastic.

- High-Carbon Steel Blades: Ideal for wood and plastic.

- Carbide-Tipped Blades: Designed for heavy-duty tasks like cutting concrete and masonry.

Tooth Design and TPI (Teeth Per Inch):

Select the appropriate tooth design and TPI based on your material:

- Variable Tooth Blades: Best for metal cutting, reducing vibrations and ensuring smoother cuts.

- High TPI Blades: Suitable for precise cuts in thin materials.

- Low TPI Blades: Ideal for faster, rough cuts in wood.

Blade Length:

- Consider the depth and accessibility of your cutting area:

- Shorter blades provide more control and are helpful for tight spaces.

- Longer blades offer extended reach for cutting through thicker materials.

Specialty Blades:

For unique tasks, such as flush cutting or pruning, select specialty blades designed for those purposes.

Universal Shank Design:

Most reciprocating saw blades today feature a universal shank design that fits most reciprocating saws on the market. This design simplifies blade changes and enhances compatibility.

Safety Considerations:

Ensure that the selected blade is appropriate for your saw’s power and speed capabilities. Using an incompatible knife may lead to safety hazards.

Read Manufacturer Recommendations:

Always refer to the manufacturer’s recommendations and instructions for blade selection. Manufacturers often guide blade compatibility and best practices.

Trial and Experience:

If you need more clarification, consider purchasing various reciprocating saw blades. This allows you to test different blades and gain experience selecting the right one for multiple tasks.

Maintenance and Inspection:

Regularly inspect your blades for signs of wear and damage. Replace worn-out or damaged blades to ensure safe and efficient cutting.

How Long Do Reciprocating Saw Blades Last?

The lifespan of reciprocating saw blades can vary widely depending on several factors, including the blade type, the materials being cut, the cutting technique, and the blade’s quality. Here are some general guidelines on how long reciprocating saw blades may last:

Blade Material:

High-Quality Blades: Premium reciprocating saw blades of high-quality materials tend to last longer. Bi-metal knives, for example, are known for their durability and extended lifespan.

Low-Quality Blades: Lower-quality or cheaper blades may wear out more quickly when cutting more rigid materials.

Material Being Cut:

Soft Materials: When cutting more delicate materials like wood and plastic, reciprocating saw blades tend to last longer because there is less wear and tear on the blade teeth.

Rugged Materials: Cutting more complex materials like metal, nails, or masonry can significantly reduce the lifespan of a reciprocating saw blade. Abrasive materials, such as concrete or brick, can wear down the edge quickly.

Cutting Technique:

Proper Technique: Using the correct cutting technique, such as letting the saw do the work and not forcing it through the material, can help prolong the blade’s life.

Improper Technique: Forcing the blade, applying excessive pressure, or using the wrong blade type for the material can lead to premature blade wear.

Blade Sharpness and Maintenance:

Blades kept sharp through regular maintenance, such as sharpening or cleaning, can last longer than neglected blades.

Removing debris, resin, or adhesive buildup from the blade teeth can help maintain cutting efficiency and extend blade life.

Frequency of Use:

Frequent use of a reciprocating saw can lead to faster blade wear. Professionals who use reciprocating saws regularly may need to replace blades more often than occasional users.

Type of Work:

The type of work performed with the reciprocating saw matters. Heavy-duty tasks like demolition or cutting through metal and nails can wear down blades faster than lighter tasks.

Blade Size and Teeth Per Inch (TPI):

Blade size and TPI can impact blade longevity. Longer blades may have more surface area to wear down, while higher TPI blades may wear faster when cutting more rigid materials.

Blade Quality:

High-quality blades from reputable manufacturers tend to last longer and maintain sharpness better than low-quality or generic blades.

Can a reciprocating saw cut wet wood?

Yes, you can cut wet wood with a reciprocating saw. Reciprocating saws are versatile tools designed to cut through various materials; damp wood is no exception. However, there are a few considerations to keep in mind when cutting wet wood with a reciprocating saw:

Blade Selection: Choose an appropriate reciprocating saw blade for cutting wet wood. Blades with a tooth design suitable for wood cutting work well in this scenario. Bi-metal blades are a common choice because they are durable and versatile, making them practical for wet and dry wood.

Safety Precautions: Cutting wet wood may create more friction and heat, leading to premature blade wear and overheating. To prevent this, periodically stop cutting to allow the blade to cool down.

Blade Lubrication: Consider applying a lubricant or cutting oil to reduce friction and prolong blade life. This can help keep the blade cool and prevent it from binding in the wet wood.

Cutting Technique: When cutting wet wood, it’s essential to maintain a steady and controlled cutting speed. Avoid forcing the saw through the wood, as this can strain the blade and saw excessively. Let the reciprocating saw do the work and guide it with even pressure.

Clean and Dry the Saw: After cutting wet wood, it’s crucial to thoroughly clean and dry the reciprocating saw. Moisture can lead to rust on the blade and saw components if left unattended. Remove the edge, clean it, and allow it to dry before storing it.

Safety First: Be cautious when working with wet wood, as it can be slippery and may pose additional safety hazards. Maintain a firm grip on the saw, use proper body positioning, and be aware of your surroundings.

Reciprocating Saw Blade Materials and Uses

Reciprocating saw blades are available in various materials, each suited to specific cutting tasks and materials. Understanding the different blade materials and their uses is essential for achieving efficient and precise cuts. Here’s an overview of reciprocating saw blade materials and their typical applications:

Bi-Metal Blades:

Material Composition: Bi-metal reciprocating saw blades are made by welding together two different types of steel. The teeth are typically made of high-speed steel, while the body is high-carbon steel.

Material Composition: High-carbon steel blades are made from a single type of high-carbon steel.

Common Uses: These blades are well-suited for cutting wood, plastic, and non-metallic materials. They are a cost-effective choice for general woodworking and DIY projects.

Carbide-Tipped Blades:

Material Composition: Carbide-tipped reciprocating saw blades feature carbide tips or teeth welded onto the blade. The body of the edge is typically made of high-carbon steel.

Common Uses: Carbide-tipped blades are designed for heavy-duty cutting tasks, such as cutting through concrete, brick, and masonry. They offer exceptional durability and longevity in demanding applications.

Diamond-Grit Blades:

Material Composition: Diamond-grit blades have a cutting edge coated with industrial-grade diamonds.

Common Uses: These blades are designed to cut hard and abrasive materials, including tile, ceramic, glass, and stone. They are ideal for tile and masonry work.

Tungsten Carbide Blades:

Material Composition: Tungsten carbide blades are made of tungsten carbide, a high-strength, wear-resistant material.

Common Uses: These blades are suitable for cutting abrasive materials like fiberglass, composite materials, and certain metals. They are often used in specialized applications.

Wood Blades:

Material Composition: Wood reciprocating saw blades are designed with specific tooth patterns optimized for cutting wood.

Common Uses: These blades are tailored for fast and efficient wood cutting. They come in various tooth configurations, including standard, fast-cut, and coarse blades for different wood types and cutting requirements.

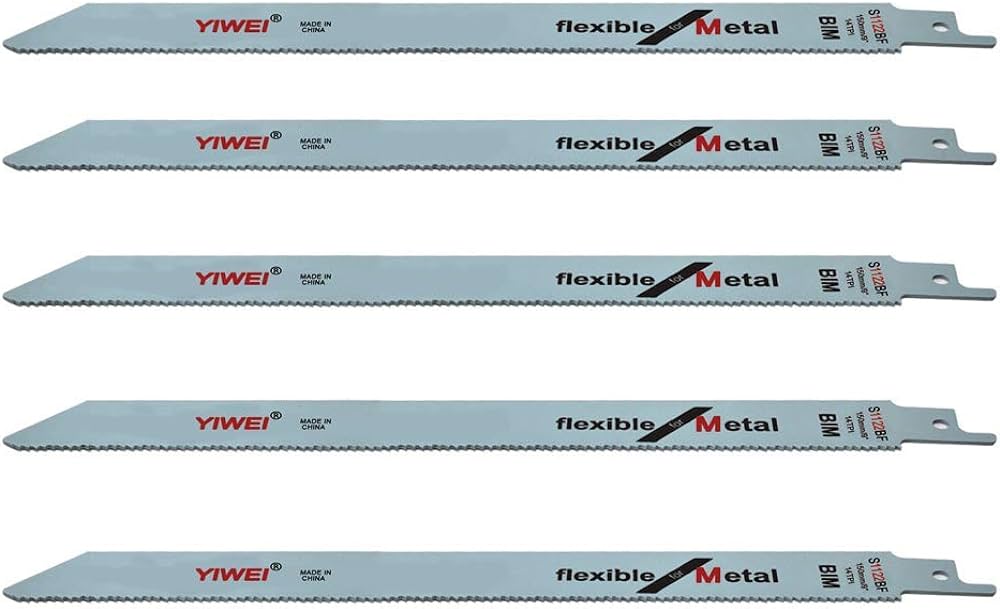

Metal Blades:

Material Composition: Metal-cutting reciprocating saw blades are designed with tooth patterns and materials optimized for cutting through metal.

Common Uses: They are used for cutting metal pipes, rods, and sheets. Variations include blades for cutting both ferrous (iron-based) and non-ferrous metals.

Pruning Blades:

Material Composition: Pruning blades typically have large, widely spaced teeth.

Common Uses: These blades are specifically designed for cutting tree branches and other vegetation in landscaping and gardening applications.

Universality

Bi-Metal Blades:

Bi-metal reciprocating saw blades are engineered by welding two distinct types of steel together. The teeth typically comprise high-speed steel, while the body is high-carbon steel.

These blades are renowned for their versatility, making them suitable for cutting through an extensive range of materials, including wood, metal, plastic, and nails. This versatility makes bi-metal blades a top choice for demolition work and general-purpose cutting, where the ability to tackle diverse materials is essential.

High-Carbon Steel Blades:

High-carbon steel reciprocating saw blades are crafted from a single type of high-carbon steel. They are well-suited for cutting wood, plastic, and non-metallic materials.

These blades are cost-effective and are commonly used in general woodworking and DIY projects where a balance of affordability and efficiency is required.

Carbide-Tipped Blades:

Carbide-tipped reciprocating saw blades feature carbide tips or teeth welded onto the blade. The blade body is typically constructed from high-carbon steel. Carbide-tipped blades are engineered for heavy-duty cutting tasks like slicing through concrete, brick, and masonry.

They are prized for their exceptional durability and longevity, making them indispensable for demanding applications.

Diamond-Grit Blades:

Diamond-grit blades are designed with a cutting edge in industrial-grade diamonds. These blades excel at cutting hard and abrasive materials, including tile, ceramic, glass, and stone. They find their niche in tile and masonry work, where precision and durability are paramount.

Tungsten Carbide Blades:

Tungsten carbide blades are constructed entirely from high-strength, wear-resistant material. These blades are often employed in specialized applications where their unique properties shine.

Wood Blades:

Wood reciprocating saw blades are optimized for wood cutting with specific tooth patterns. They come in various configurations, including standard, fast-cut, and coarse blades, catering to different wood types and cutting requirements. These blades are cherished for their efficiency in woodworking, allowing for swift and accurate cuts.

Metal Blades:

Metal-cutting reciprocating saw blades are engineered with tooth patterns and materials tailored for slicing through metal. They are utilized for cutting metal pipes, rods, and sheets.

Variations include blades designed for ferrous (iron-based) and non-ferrous metals, ensuring compatibility with various metalworking tasks.

Pruning Blades:

Pruning blades stand out with large, widely spaced teeth. They are specifically designed for cutting tree branches and other vegetation, finding their place in landscaping and gardening applications.

Conclusion

Reciprocating saw blades are indispensable for construction, woodworking, and DIY projects. They come in various materials, each carefully designed for specific cutting tasks and materials. Understanding these blade materials’ characteristics and typical applications is crucial for achieving precise and efficient cuts.