In this article we are going to discuss (Can scroll saw cut metal?) in detail. Actually a scroll saw is primarily designed for cutting wood and other soft materials and is not typically used for cutting metal.

This limitation is because scroll saws typically operate at relatively low speeds, and their blades are optimized for cutting through softer materials.

Different type of tool To cut metal

To cut metal, significantly harder metals like steel or aluminum, you would generally need a different type of tool, such as:

1. Metal-Cutting Bandsaw: Bandsaws designed for cutting metal have the necessary blade speed and rigidity to cut through metal effectively.

2. Angle Grinder with a Cutting Wheel: Angle grinders equipped with cutting wheels or abrasive discs are versatile tools for cutting various types of metal.

3. Metal-Cutting Jigsaw: There are jigsaw blades specifically designed for cutting metal. However, these are typically used for thinner metal sheets rather than thick metal stock.

4. Plasma Cutter or Oxy-Fuel Torch: Plasma cutters and oxy-fuel torches are commonly used for heavy-duty metal cutting, especially in industrial settings. Additionally, wear appropriate personal protective equipment such as safety glasses, gloves, and hearing protection when working with metal-cutting tools.

Cutting metal with a scroll saw

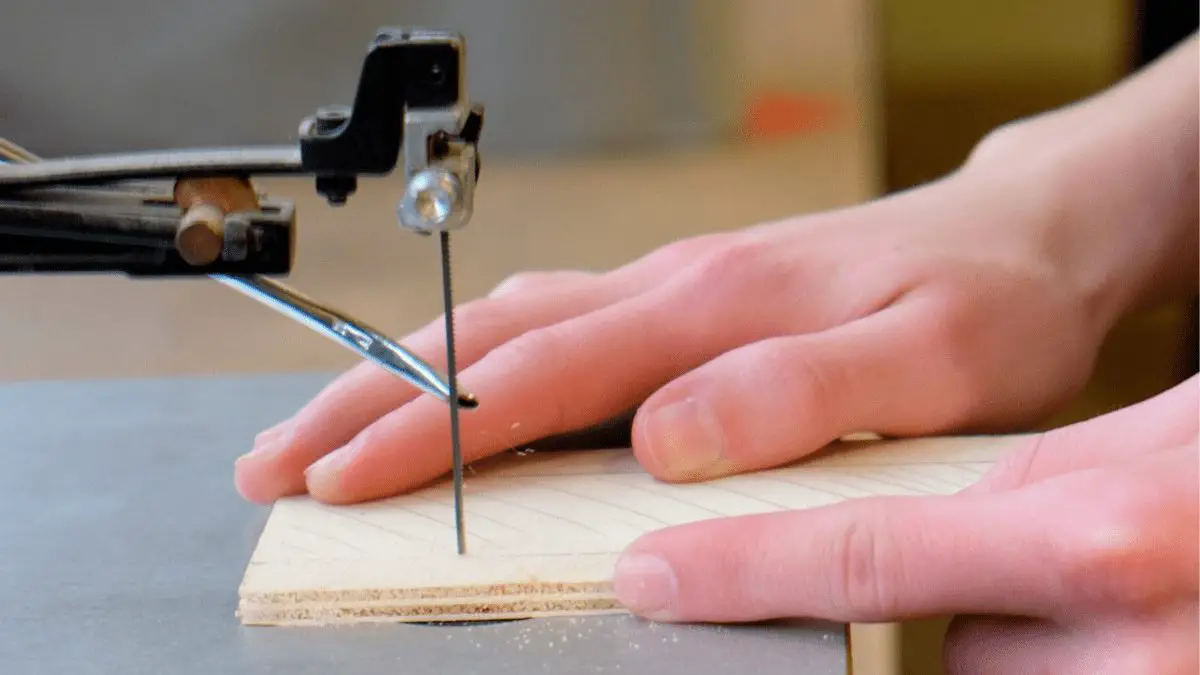

Cutting metal with a scroll saw is possible under certain conditions, but it’s important to remember that it is primarily designed for cutting wood and other soft materials. If you want to attempt cutting metal with a scroll saw, here are five key factors to consider:

1. Blade Selection: Choose the appropriate blade for cutting metal. Scroll saw blades come in various types and tooth configurations. For cutting metal, you’ll need blades designed for metal cutting.

2. Blade Tension: Proper blade tension is critical. Adjust the tension on your scroll saw to ensure the blade is taut and doesn’t wobble during cutting. This helps maintain accuracy and prevents blade breakage.

3. Speed Control: Many scroll saws have variable speed controls. When cutting metal, you must set the saw to a lower speed than you would use for wood. This slower speed reduces heat buildup and minimizes blade wear.

4. Coolant or Lubrication: Metal cutting generates heat, which can lead to premature blade wear. Consider using a coolant or lubricant while cutting metal to help dissipate heat and prolong blade life. Some options include cutting oil or wax sticks designed for metalworking.

5. Material Thickness and Type: Scroll saws are better suited for thin and soft metals such as aluminum, brass, or copper. Attempting to cut thick or hard metals like steel with a scroll saw is not recommended. Ensure the metal you intend to cut is within the capabilities of your scroll saw.

Skip tooth blades

Skip tooth blades are a type of scroll saw blade commonly used for various woodworking applications, particularly with scroll saws. These blades are characterized by their tooth pattern, which features significant gaps or skips between the teeth. Skip tooth blades have some specific advantages and uses:

1. Fast Cutting: The design of skip tooth blades allows for faster cutting, making them well-suited for quickly removing material during scroll saw projects.

2. Chip Removal: The significant gaps between the teeth in skip tooth blades help with efficient chip removal. This is particularly useful when cutting through thicker or denser materials, as it reduces the chance of clogging and overheating.

3. Smooth Cuts: While skip tooth blades are known for their speed, they can still provide relatively smooth and precise cuts, mainly when used with hardwoods or softwoods.

4. Versatility: Skip tooth blades can handle various woodworking tasks, including intricate designs, curves, and straight cuts.

5. Thicker Materials: They are often chosen for cutting thicker materials, such as hardwoods or plywood, due to their efficient chip removal and cutting speed.

6. Less Aggressive: Skip tooth blades are less aggressive than some other blade types, making them suitable for detailed work where a more delicate touch is required.

Spiral blades

Spiral blades are another type of scroll saw blade used for various woodworking applications, particularly when intricate and detailed cuts are required. Unlike standard straight blades, spiral blades have a unique helical or twisted shape, which offers some distinct advantages:

1. Versatility: Spiral blades are incredibly versatile and can cut in any direction—forward, backward, or sideways. This makes them ideal for creating intricate and complex cuts, including intricate patterns, curves, and inside cutouts.

2. No Pilot Holes: Because of their design, spiral blades don’t require pilot holes to start cuts. This is especially useful when cutting inside a piece of wood without drilling a starting hole.

3. Efficient Dust Removal: The twisting design of spiral blades allows for efficient chip and dust removal during cutting. This helps maintain a cleaner workspace and prevents overheating.

4. Smooth Cuts: Spiral blades are known for producing smooth and precise cuts, making them suitable for scroll saw projects requiring great detail and accuracy.

5. Less Blade Breakage: The spiral shape of the blade provides increased flexibility, reducing the likelihood of blade breakage significantly when cutting tight curves.

6. Thickness Tolerance: Spiral blades can handle various material thicknesses, making them suitable for thin and thick wood.

7. Reduced Cutting Width: Spiral blades have a smaller cutting width than other blade types, allowing for finer, more delicate cuts.

Spiral blades come in different sizes and tooth configurations, such as regular, reverse, and double reverse spirals, allowing you to choose the most appropriate blade for your project. Remember that, like other scroll saw blades, spiral blades will wear out over time and require replacement.

Jeweler’s Blades

Jeweler blades, often referred to as jewelry saw blades or jeweler’s saw blades, are specialized cutting tools used by jewelers and metalsmiths for precision cutting of various materials in jewelry making and metalwork. These blades are typically skinny and delicate, allowing for intricate and fine cuts in precious metals and other materials. Here are some key features and uses of jeweler’s blades:

1. Thin and Fine: Jeweler blades are skinny and refined, allowing jewelers to make precise cuts with minimal material wastage. They are often thinner than other saw blades, making them suitable for cutting delicate and intricate designs in thin materials.

2. High Precision: These blades are designed for precision work, allowing jewelers to create intricate patterns, shapes, and designs in gold, silver, copper, and brass. They are also used for cutting gemstones, bone, plastic, and other materials commonly used in jewelry making.

3. Versatility: Jeweler’s blades can cut through various materials used in jewelry making, making them versatile tools for various tasks, including piercing, sawing, and cutting fine details.

4. Different Tooth Configurations: Jeweler blades come in various tooth configurations to suit different materials and cutting requirements. For example, some blades have finer teeth for cutting metal, while others may have coarser teeth for cutting softer materials.

5. Frame or Piercing Saws: These blades are used with jewelry or piercing saw frames, which hold the blade in tension and provide stability during cutting. The frames allow for controlled, freehand cutting.

6. Blade Replacement: Jeweler’s blades are delicate and break easily if subjected to excessive pressure or lateral force. Jewelers often need to replace blades frequently to maintain precise cutting.

What Can You Not Do With a Scroll Saw?

Scroll saws are versatile tools for cutting intricate curves, shapes, and patterns in various materials, but there are limitations to what they can do. Here are some things you generally cannot do with a scroll saw:

1. Cut Thick Metal: Scroll saws are not designed for cutting thick or hard metals like steel. Attempting to cut such materials can damage the blade and the saw, and it’s not safe.

2. Rip Long Straight Cuts: Scroll saws are not meant to make long, straight cuts like a table saw. They excel at making curved and intricate cuts but are designed for something other than ripping or cross-cutting large pieces of lumber.

3. Resawing: Resawing involves cutting a thick board into thinner pieces. Scroll saws are unsuitable for this task, as they need more power and capacity to cut through thick boards.

4. Dado or Groove Cuts: Creating dadoes or grooves typically used for joinery is not practical with a scroll saw. Table saws or router tables are better suited for such cuts.

5. Bevel Cuts: Scroll saws are not designed for bevel or angled cuts. A miter or table saw would be more appropriate if you need to make angled cuts.

6. Large Stock: Scroll saws are best suited for working with smaller pieces of material. Cutting large, heavy pieces can be challenging and lead to inaccurate cuts.

7. Thick Hardwoods: While scroll saws can cut through various types of wood, extremely hard or dense hardwoods can be difficult to work with on a scroll saw, especially if the wood is thick.

8. High-Production or Heavy-Duty Work: Scroll saws are typically used for intricate and detailed projects but are meant for something other than heavy-duty, high-production work. Larger and more robust saws like bandsaws or CNC routers are better choices for such tasks.

9. Straight Line Cutting: Scroll saws can make straight cuts but are less efficient than other saws. Other saws are more suitable if you primarily need to make straight cuts.

The following methods are commonly used to cut thick metal

1. Plasma Cutting: Plasma cutting is a versatile method for cutting thick metal. It uses a plasma torch that generates a high-temperature, ionized gas (plasma) to melt through the metal. It’s suitable for various metals, including steel, stainless steel, and aluminum.

2. Oxy-Fuel Cutting:Oxy-fuel cutting is effective for cutting thick steel.

3. Laser Cutting: Laser cutting is a precise and efficient method for cutting thick metal. Laser cutting is suitable for various metals but is commonly used for steel, stainless steel, and aluminum.

4. Waterjet Cutting: This versatile method can cut various materials, including metals, plastics, and composites.

5. Band Saw: A metal-cutting bandsaw with a suitable blade can cut through thick metal. It is a slower process than other methods, but it is effective for straight cuts and is often used in metalworking shops.

6. Abrasive Cutting Tools: Abrasive cutting tools like angle grinders with cutting wheels or abrasive chop saws can be used to cut thick metal. These tools are handheld and can make both straight and curved cuts.

7. Shearing: Shearing involves using mechanical or hydraulic shear to cut thick metal sheets. It’s commonly used for straight cuts in sheet metal and plate.

8. Plasma Arc Gouging: While primarily used for gouging or removing metal, plasma arc gouging can also be used for cutting thick metal when more traditional cutting methods are unavailable.

9. Torch Cutting: Torch cutting with an oxy-acetylene torch or similar equipment can be used for less precise cutting needs. It’s a slower method but can effectively cut thick metal in specific applications.

Metal Type

The type of metal you choose for a particular project depends on various factors, including the intended use, desired properties, and budget constraints. Here are some common types of metals used in various applications:

1. Steel: Steel is one of the most widely used metals due to its strength, durability, and versatility. Carbon steel is commonly used in construction and manufacturing, while stainless steel is known for its corrosion resistance and is used in kitchen appliances, medical equipment, and architectural applications.

2. Aluminum: Aluminum is lightweight, corrosion-resistant, and has good conductivity. It’s commonly used in aerospace, automotive parts, construction, and electrical wiring. Aluminum alloys, such as 6061 and 7075, offer different properties and are used for various applications.

3. Copper: Copper is an excellent conductor of electricity and heat. It’s used in electrical wiring, plumbing, roofing, and making coins and decorative items. Copper alloys like bronze and brass have unique properties and are used in art, musical instruments, and bearings.

It’s used in musical instruments, decorative hardware, plumbing fixtures, and fittings.

5. Bronze: Bronze is an alloy of copper and other elements, such as tin, aluminum, or silicon. It’s used in sculptures, bearings, gears, and historical artifacts due to its corrosion resistance and attractive patina.

6. Titanium: Titanium is lightweight, strong, and corrosion-resistant, making it suitable for aerospace, medical implants, and sports equipment.

7. Nickel: Nickel and nickel alloys offer excellent resistance to heat, corrosion, and wear. They are used in chemical processing, electrical components, and aerospace applications.

8. Lead: Lead is dense and has excellent shielding properties against radiation. It’s used to construct radiation shields, batteries, and some types of solder.

9. Zinc: Zinc is often used as a protective coating for steel (galvanized steel) to prevent corrosion. It’s also used in die-casting, batteries, and roofing materials.

10. Tin: Tin is known for its low toxicity and corrosion resistance. It coats other metals (tin plating) to prevent corrosion and produce solder.

11. Precious Metals: They are used in jewelry, coins, electronic components, and investment assets.

Safety

Safety is paramount when cutting metal with a scroll saw or other power tool. Here are some safety rules and guidelines to follow when working with a scroll saw to cut metal:

1. Wear Appropriate Personal Protective Equipment (PPE):

- · Safety glasses or a face shield: Protect your eyes from flying debris and metal particles.

- · Hearing protection: Scroll saws can be noisy, significantly when cutting metal.

- · Respirator or dust mask: Prevent inhaling metal dust or fumes, significantly when cutting materials that may produce harmful fumes.

- · Gloves: Wear appropriate gloves to protect your hands from sharp edges and heat.

2. Inspect the Scroll Saw:

- · Before starting work, ensure the scroll saw is in good condition. Check for loose parts, damaged blades, and proper blade tension.

3. Choose the Right Blade:

- · Select the appropriate type and size of blade for cutting metal. Consult the manufacturer’s recommendations for the scroll saw and blade compatibility.

4. Secure the Workpiece:

- · Ensure the metal workpiece is securely clamped or fastened to the saw table. This prevents the material from shifting or moving during cutting.

5. Set the Correct Speed:

- · Adjust the scroll saw’s speed to an appropriate level for cutting metal. Lower speeds are usually recommended for metal cutting to reduce heat and prevent blade wear.

6. Use Lubrication or Coolant:

- · Consider using a suitable cutting oil or coolant to reduce friction heat buildup and prolong blade life during metal cutting.

7. Start Slowly:

- · When you begin cutting, start at a slow and steady pace. This allows you to control the cut and prevents the blade from binding or breaking.

8. Keep Hands Clear:

- · Always keep your hands and fingers safe from the moving blade. Use a push stick or other appropriate tools to guide the workpiece.

9. Avoid Forceful Feeding:

- · Let the blade cut; do not force the workpiece into the blade. Excessive pressure can lead to blade breakage or poor cutting results.

10. Maintain Good Visibility:

- · Ensure proper lighting in your workspace to see the cutting line and workpiece clearly. Adequate visibility is essential for accurate cuts.

11. Stay Alert and Focused:

- · Being attentive can help prevent accidents.

12. Keep the Workspace Clean:

- · Remove metal chips, dust, and debris from the work area regularly. A clean workspace reduces the risk of accidents and fires.

13. Follow Manufacturer’s Instructions:

- · Always adhere to the manufacturer’s safety recommendations and guidelines in the scroll saw’s user manual.

14. Turn Off the Saw When Not in Use:

- · When taking breaks or making adjustments, turn off the scroll saw and wait for it to come to a complete stop before making any changes.

15. Properly Dispose of Waste:

- · Dispose of metal shavings and waste materials following local regulations. Some metal shavings can be sharp and hazardous.

Conclusion

Cutting metal with a scroll saw is possible but comes with considerations and limitations. Scroll saws, primarily designed for cutting wood and softer materials, can be used for cutting metal correctly and safely. Here are the key takeaways: