When it comes to woodworking tools, the choice between a bandsaw vs. circular saw can be a game-changer. These two powerhouses stand as cornerstones in cutting and shaping materials. The bandsaw, known for its finesse in curved cuts, and the circular saw, celebrated for its straightforward precision, both hold their ground.

Navigating the bandsaw vs. circular saw dilemma requires a grasp of their unique strengths and applications. So, if you’re pondering over which tool to wield for your next project, buckle up as we explore into the nuances of these cutting champions. Get ready to explore the key distinctions and uncover which tool emerges victorious for your woodworking aspirations.

CIRCULAR SAW MACHINE ADVANTAGES

Circular saw machines have revolutionized the world of woodworking and cutting, providing efficient and precise solutions for a wide range of applications.

These versatile tools have become indispensable in various industries, from construction to carpentry. This article explores into the numerous advantages circular saw machines bring, showcasing why they are a must-have for professionals and enthusiasts alike.

1. Precision and Accuracy

One of the standout features of circular saw machines is their exceptional precision and accuracy. Equipped with sharp and high-quality blades, these machines can make clean and precise cuts through various materials, ensuring the result is of the highest quality. Whether you’re working on intricate designs or large-scale projects, the accuracy offered by circular saw machines is unparalleled.

2. Versatility in Materials

Circular saw machines are designed to handle a diverse range of materials with ease. From hardwoods to softwoods, plastics to metals, these machines are adaptable and capable of delivering consistent results across different materials. This versatility makes them an essential tool for professionals who work with various materials in their projects.

3. Efficiency and Time-Saving

In the fast-paced world of modern industry, time is of the essence. Circular saw machines are efficient, allowing operators to complete tasks quickly and effectively. The powerful motor and advanced blade design ensure swift cutting, reducing downtime and increasing productivity. This efficiency translates to cost savings and the ability to take on more projects within a given timeframe.

4. Ease of Use and Portability

Circular saw machines are designed with user-friendliness in mind. With ergonomic handles, intuitive controls, and precise cutting guides, beginners can achieve professional-grade results. Additionally, many circular saw models’ compact and lightweight design makes them easily portable, enabling users to take their work to different locations without hassle.

5. Variety of Cutting Applications

Whether straight cuts, bevel cuts, or angled cuts, circular saw machines excel in various cutting applications. Their ability to adapt to different cutting angles and depths makes them indispensable for tasks that demand precision and flexibility. From constructing furniture to framing structures, circular saw machines are a go-to choice for professionals seeking versatility.

6. Cost-Effective Solution

Circular saw machines offer a cost-effective solution for individuals and businesses alike. Compared to larger cutting equipment, these machines are relatively affordable, making them accessible to a broader range of users. Their durability and long lifespan ensure the initial investment pays off, making them a valuable addition to any workshop.

7. Enhanced Safety Features

Modern circular saw machines have advanced safety features that prioritize user protection. These safety features, from blade guards to anti-kickback mechanisms, minimize the risk of accidents and injuries during operation. This focus on safety ensures a secure working environment, allowing users to focus on their tasks without unnecessary concerns.

DOWNSIDES OF CIRCULAR SAW MACHINES

Circular saw machines have undoubtedly revolutionized the cutting and woodworking industries, providing efficiency and precision. However, like any tool, they come with drawbacks that users should be aware of. This article will discuss the challenges and considerations associated with using circular saw machines.

Safety Concerns

While circular saw machines come equipped with safety features, there’s always a risk associated with any power tool. The sharp and powerful blades can cause severe injuries if not handled carefully. Accidents can happen, especially if users must be adequately trained in proper operating techniques or follow safety guidelines.

Noise and Vibration

Circular saw machines can generate significant noise and vibration during operation. Proper protective gear, such as ear protection and anti-vibration gloves, is essential to mitigate these issues.

Dust and Debris

The cutting process generates a substantial amount of dust and debris, posing health hazards to the operator and the surrounding environment. Inhaling fine particles can lead to respiratory issues, and the accumulation of debris can create a messy workspace. Using proper dust extraction systems and wearing respiratory protection are crucial steps in minimizing these concerns.

Limited Portability

While some circular saw machines are designed to be portable, others may be bulkier and less convenient to transport. This limitation can be a drawback for professionals who need to move their equipment to different job sites. Additionally, the need for a power source limits the machine’s usability in remote or off-grid locations.

Depth and Angle Limitations

Circular saw machines excel in many cutting applications. Still, they do have limitations when it comes to cutting depth and angle adjustments. Projects requiring deep cuts or intricate bevel angles may require additional tools or techniques. Users should be prepared to work within the limitations of the machine’s capabilities.

Skill and Experience

Achieving precise cuts with a circular saw machine requires a certain level of skill and experience. Novice users might need help to maintain consistent cuts or achieve the desired level of precision. This learning curve can lead to wasted materials and frustration once the operator becomes proficient with the tool.

Maintenance and Blade Changes

Regular maintenance is essential to keep circular saw machines in optimal condition. Blades can become dull over time, affecting the quality of cuts and potentially increasing the risk of accidents. Changing blades and performing routine maintenance tasks can be time-consuming and require technical know-how.

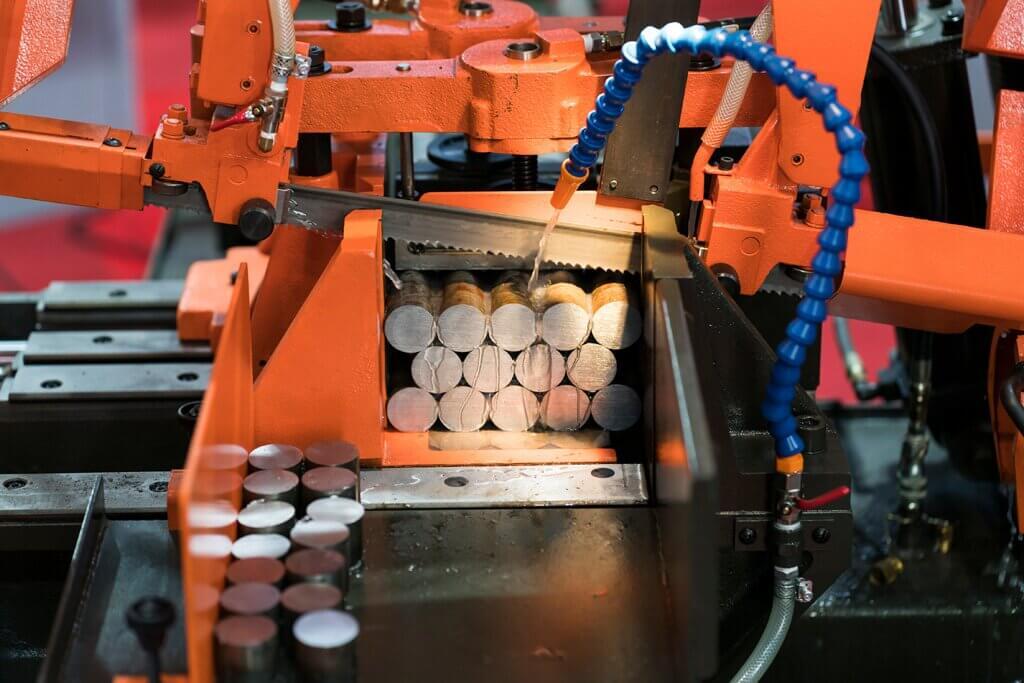

BAND SAW MACHINE ADVANTAGES

The band saw machines stand as versatile and essential tools in the realm of cutting and woodworking. These powerful devices have gained prominence for their ability to make precise cuts across a range of materials.

1. Precision in Every Cut

Its remarkable precision lies at the heart of a band saw machine’s allure. Equipped with a continuous looped blade, these machines excel in producing smooth, accurate cuts that meet the highest standards of craftsmanship. Whether it’s intricate curves, straight lines, or detailed patterns, the precision offered by band saw machines is unmatched.

2. Versatility across Materials

The band saw machines demonstrate exceptional versatility when it comes to materials. From wood and metal to plastics and even composites, these machines are easily able to handle a diverse range of materials. This adaptability makes band saws a go-to choice for furniture manufacturing and metalworking industries.

3. Enhanced Control and Flexibility

The adjustable nature of band saw machines provides users with enhanced control and flexibility during the cutting process. Adjusting the blade speed, tension, and angle allows customization based on the material and desired outcome. This adaptability empowers craftsmen and professionals to achieve their creative visions with precision and finesse.

4. Minimal Material Wastage

The band saw machines are designed to minimize material wastage, making them an economical choice for individuals and businesses. The thin blade design reduces the kerf width, ensuring less material is lost during cutting. This translates to cost savings and a more sustainable approach to crafting.

5. Curved and Intricate Cuts

Unlike some other cutting tools, the band saw machines excel in producing curved and intricate cuts. The continuously looped blade allows easy maneuverability around tight corners and complex contours. This capability opens the door to design possibilities, enabling artisans to create intricate and visually stunning pieces.

6. Reduced Vibration and Noise

Band saw machines are designed with features that minimize vibration and noise levels during operation. This improves the operator’s comfort and contributes to a quieter and more pleasant working environment. The reduced vibration also enhances the accuracy of cuts, ensuring consistent results.

7. Safety and Operator-Friendly Features

Modern band saw machines have safety features that prioritize the operator’s well-being. Blade guards, anti-kickback mechanisms, and emergency stop buttons provide a secure working experience. Additionally, the ergonomic design of many band saw models reduces operator fatigue during extended use.

DOWNSIDES OF BAND SAW MACHINES

Band saw machines have earned their place as versatile tools in cutting and woodworking. However, like any tool, they come with drawbacks that users should be aware of. In this article, we’ll explore into the downsides of band saw machines, shedding light on the challenges and considerations associated with their usage.

1. Learning Curve and Skill

While band saw machines offer precision and versatility, mastering their operation requires skill and experience. Achieving accurate cuts, particularly for intricate designs, may prove challenging for beginners. Adjusting blade tension, tracking, and other settings demands patience and practice to achieve optimal results.

2. Limited Throat Capacity

Band saw machines are designed with a specific throat capacity, determining the maximum width of material that can be cut. This limitation can hinder working with more extensive pieces of wood or other materials. Users must carefully select their machine based on the size of projects they anticipate undertaking.

3. Blade Maintenance and Breakage

The blades of band saw machines require regular maintenance to ensure optimal performance. Dull or damaged blades can result in uneven cuts and decreased efficiency. Additionally, blades are susceptible to breakage if not used correctly or if the machine encounters unexpected hard materials during operation.

4. Slower Cutting Speed

Band saw machines tend to have a slower cutting speed than some other cutting tools. This can be a drawback for professionals or projects that require rapid cuts. While the slower speed contributes to precision, users must factor in the additional time needed to complete tasks.

5. Complexity of Adjustments

While band saw machines offer adjustable features, fine-tuning these settings can be intricate and time-consuming. Achieving the ideal blade tension, tracking, and angle adjustments may involve trial and error. Users must familiarize themselves with the machine’s mechanics to optimize its performance.

6. Noise and Vibration

Like other power tools, the band saw machines generate noise and vibration during operation.

7. Space and Footprint

A band saw machines, significantly larger models, require significant space in a workshop. The machine’s footprint can limit the workspace for other tasks or equipment. Users with limited space must carefully consider the machine’s dimensions before purchasing.

Bandsaw vs. Circular Saw: What Are the Differences?

In the world of cutting and woodworking, two prominent contenders stand out: the bandsaw and the circular saw. These two tools have garnered recognition for their ability to make precise cuts across various materials.

1. Design and Blade Configuration

- Bandsaw

The bandsaw features a continuous looped blade that runs over two or more wheels. This design allows for intricate curved cuts and exceptional precision. The blade’s vertical orientation enables smooth vertical cuts. It makes it well-suited for resawing tasks to create thinner boards from larger pieces of material.

As the name suggests, the circular saw employs a circular blade mounted on an arbor. This design facilitates straight cuts through various materials. While circular saws can accommodate various blade sizes, they are primarily known for their efficiency in making crosscuts and ripping through lumber.

2. Cutting Versatility

- Bandsaw

Bandsaw machines excel in cutting versatility, particularly regarding curves and irregular shapes. Their ability to navigate intricate contours makes them a preferred choice for intricate woodworking projects. Bandsaws are often used for projects that demand artistic designs, intricate joinery, and curved components.

Circular saw machines offer efficiency and speed in straight cuts. Their straightforward design makes them suitable for applications that require long, continuous cuts, such as cutting plywood sheets or framing lumber. While they lack the bandsaw’s curved cutting capabilities, circular saws are indispensable for projects prioritizing straight-line accuracy.

3. Cutting Depth and Thickness

- Bandsaw

Bandsaw machines are renowned for their capacity to cut through thicker materials due to their larger throat capacity. This makes them ideal for resawing thicker boards and creating veneers from hardwoods.

- Circular Saw

Circular saws are limited in cutting depth compared to bandsaw machines. While they are efficient for crosscuts and rips in thinner materials, they might need help with thicker workpieces.

4. Precision and Accuracy

- Bandsaw

Bandsaw machines excel in precision, particularly for intricate and detailed cuts. Their continuous blade design allows for fine adjustments, resulting in smoother edges and minimal waste.

- Circular Saw

Circular saws offer reliable accuracy for straight cuts. However, achieving the same level of precision for intricate or curved cuts can be challenging.

5. Space and Portability

- Bandsaw

Bandsaw machines, significantly larger models, require more workshop space due to their size and design. Their stationary nature makes them less portable.

- Circular Saw

Circular saws are relatively compact and portable, making them suitable for various job sites. Their mobility makes them a preferred choice for tasks that demand flexibility.

Comparing Bandsaws and Circular Saws with Other Tools

In cutting and woodworking, bandsaws and circular saws are prominent contenders, each offering unique features and advantages. However, they are not the only tools in the toolbox. Let’s look at how bandsaws and circular saws compare with other tools commonly used for cutting tasks, shedding light on their strengths and limitations.

1. Jigsaw vs. Bandsaw and Circular Saw

- Jigsaw

Jigsaws are versatile handheld tools that excel in making intricate curved cuts. They are ideal for projects that require artistic designs, irregular shapes, and detailed cutouts. Jigsaws are portable and offer excellent maneuverability.

- Bandsaw

Bandsaws offer enhanced precision and stability for curved cuts compared to a jigsaw. Their continuous looped blade allows for smoother motion and more accurate results, making them suitable for more complex woodworking projects.

- Circular Saw

While circular saws lack the jigsaw’s ability to navigate intricate curves, they excel in straight cuts. They are efficient for projects, prioritizing speed and precision when cutting through various materials.

2. Table Saw vs. Bandsaw and Circular Saw

- Table Saw

Table saws are stationary tools with a circular blade protruding from a flat surface. They excel in straight cuts and are used for ripping, crosscutting, and making dado cuts. Table saws are versatile and offer a wide range of cutting options.

- Bandsaw

Bandsaws complement table saws by excelling in curved cuts and intricate designs. Their vertical blade orientation allows for detailed contouring that table saws cannot achieve.

- Circular Saw

Circular saws are portable counterparts to table saws, providing mobility and flexibility. While they lack the table saw’s stability and precision, they are suitable for various job-site cutting tasks.

3. Scroll Saw vs. Bandsaw and Circular Saw

- Scroll Saw

Scroll saws are specialized tools designed for intricate scrollwork and delicate cuts. They feature a thin blade that moves up and down, allowing for precise and detailed cutting in thin materials.

- Bandsaw

Bandsaws can handle a broader range of materials and are more versatile than scroll saws. While both excel in curved cuts, bandsaws offer greater capacity for thicker materials and larger projects.

- Circular Saw

Circular saws offer straight-line cutting capabilities and are not ideal for the intricate work that scroll saws excel in. However, they are more versatile in materials and can handle thicker stock.

4. Reciprocating Saw vs. Bandsaw and Circular Saw

- Reciprocating Saw

Reciprocating saws are versatile handheld tools designed for demolition and rough cuts. They feature a push-pull motion and are ideal for cutting through wood, metal, and plastics.

- Bandsaw

Bandsaws are precision tools that excel in curved cuts and intricate designs. They are not designed for the same rough cutting tasks as reciprocating saws but offer exceptional accuracy and stability.

- Circular Saw

They offer cleaner and more controlled cuts, making them suitable for rough and precise cutting tasks.

Conclusion

The debate between bandsaws and circular saws hinges on woodworkers’ and DIY enthusiasts’ specific needs and preferences. Bandsaws excel in intricate curved cuts and resawing tasks, offering greater precision and versatility for specialized woodworking.

On the other hand, circular saws boast portability and the ability to handle various materials, making them a go-to option for general construction and framing tasks.

When deciding between these two saw types, it’s crucial to consider factors such as the complexity of the cuts required, the workspace available, and the materials used. Bandsaws provide finesse and accuracy for detailed work. At the same time, circular saws offer convenience and adaptability for a broader range of applications.