When it comes to woodworking and construction, choosing the right tool can make all the difference in the precision and efficiency of your projects.

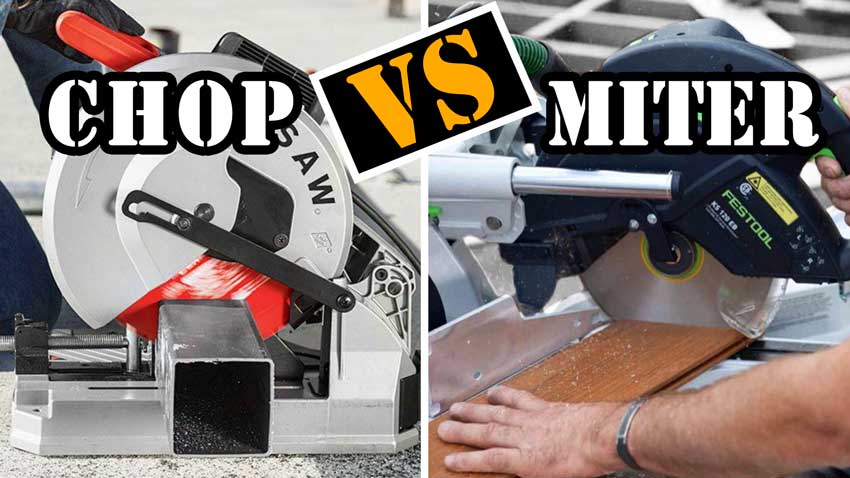

You’ve probably found yourself at the crossroads of deciding between (Chop saw vs miter saw). These two heavy hitters in the world of power tools have distinct features and applications that can significantly impact the outcome of your work.

Comparison of Chop Saw and Miter Saw

Key Differences

1. Cutting Angle Range

Chop Saw: A Chop Saw, also known as a cutoff saw, is primarily designed for making straight 90-degree cuts. It excels at quickly and accurately cutting through materials like metal, steel, or concrete. However, it needs more versatility to make angled cuts.

Miter Saw: A Miter Saw, on the other hand, is renowned for its versatility in making precise angled cuts. It can pivot its blade at various angles, typically ranging from -45 degrees to +45 degrees horizontally. This feature makes it ideal for tasks that require precise mitered and beveled cuts.

2. Bevel Cutting

Chop Saw: Typically, Chop Saws do not have a beveling function, limiting their ability to make beveled cuts for molding and framing work.

Miter Saw: Miter Saws have a bevel function, allowing the blade to tilt to one side. This feature enables users to create beveled edges, making it a preferred choice for intricate woodworking projects.

3. Portability

Chop Saw: Chop Saws are generally bulkier and heavier, making them less portable. They are often mounted on a stable base, making them suitable for stationary use in workshops or construction sites.

Miter Saw: Miter Saws are relatively more portable due to their lighter weight and compact design. Some models even come with handles for easy transportation, making them a versatile choice for on-site and off side work.

4. Dust Collection

Chop Saw: These tools often lack efficient dust collection systems, resulting in a messier work environment. Users frequently need to employ additional measures to control dust and debris.

Miter Saw: Miter Saws are typically equipped with better dust collection systems, minimizing the mess and keeping the workspace cleaner. This feature enhances overall efficiency and safety during operation.

Similarities

While Chop Saws and Miter Saws have distinct differences, they also share some common traits:

1. Blade Types

Both tools use circular blades that rotate at high speeds to make precise cuts. Users can choose from various blade types, depending on the material they intend to cut.

2. Motor Power

Both Chop Saws and Miter Saws have powerful motors designed to handle rigid materials effectively. The motor power can vary depending on the specific model, but both can handle demanding cutting tasks.

3. Safety Features

Safety is a top priority in the design of these saws. Both have safety features such as blade guards, trigger locks, and anti-kickback mechanisms to protect users during operation.

Pros and Cons of Chop saw vs miter saw

Now, let’s weigh the advantages and disadvantages of each type of saw to help you make an informed decision:

Chop Saw Pros:

- Efficiency: Chop Saws are exceptionally efficient at straight cuts in rigid materials, making them ideal for heavy-duty applications.

- Durability: They are built to withstand rugged use, ensuring longevity.

- Speed: These saws are known for their speed, allowing for quick and efficient cuts

Chop Saw Cons:

- Lack of Versatility: Their inability to make angled or beveled cuts limits their suitability for specific woodworking projects.

- Portability: Chop Saws are less portable and may require a stationary setup.

Miter Saw Pros:

- Versatility: Miter Saws excels at making precise angled and beveled cuts, making them indispensable for woodworking projects that demand accuracy.

- Portability: Their compact design and handles make them more portable and versatile.

- Dust Collection: Better dust collection systems contribute to a cleaner workspace.

Miter Saw Cons:

- Cost: Miter Saws are more expensive than Chop Saws due to their versatility and additional features.

- Maintenance: The moving parts and beveling mechanisms may require more maintenance over time.

Chop Saw Overview

In the world of power tools, the Chop Saw stands out as a versatile and indispensable tool, especially in construction and metalworking. This overview will delve into what a Chop Saw is, the various types available, and their typical uses, providing you with a comprehensive understanding of this essential tool.

What is a Chop Saw?

A Chop Saw, often called a cutoff saw, is a specialized power tool designed for making straight, precise cuts in various materials, primarily metal, steel, and sometimes wood or plastics. It is recognized for its robust build, high-powered motor, and circular blade that rotates at high speeds to deliver efficient and accurate cuts.

Types of Chop Saws

Chop Saws come in several types, each catering to specific needs and applications. Here are some common types of Chop Saws:

1. Abrasive Chop Saw

Abrasive Chop Saws are commonly used for cutting metal and steel. They employ an abrasive disc, similar to a grinding wheel, to cut through materials. These are suitable for tasks where speed is essential, such as construction and metal fabrication.

2. Cold Saw

A Cold Saw is designed to cut metal tubes, pipes, and solid bars. Unlike abrasive Chop Saws, Cold Saws use a toothed, high-speed, low-heat-producing blade. This results in cleaner, burr-free cuts, making it ideal for precision metalwork.

3. Dry Cut Chop Saw

Dry Cut Chop Saws are known for their ability to cut metal without the need for coolant or lubrication. They use carbide-tipped blades, which can last longer than abrasive discs. These saws are popular among professionals for their efficiency and clean cuts.

4. Wood Chop Saw

While Chop Saws are predominantly used for metalwork, some models come with the versatility to cut wood and plastic materials as well. These are equipped with specialized blades suitable for woodworking tasks.

Typical Uses

Chop Saws find applications in various industries and projects due to their ability to deliver precise and efficient cuts. Here are some typical uses:

Construction

In the construction industry, Chop Saws are employed to cut steel beams, pipes, and other structural components. Their speed and accuracy make them invaluable for creating precise cuts in construction materials.

Metal Fabrication

Metalworkers use Chop Saws extensively to cut metal rods, bars, and sheets. The clean cuts achieved by Cold Saws, mainly, are crucial for fabricating metal components used in machinery and equipment.

Woodworking

Some Chop Saws are equipped with the capability to cut wood and plastic. Woodworkers use these saws for making straight cuts in lumber and other wooden materials, aiding in tasks like framing and molding.

Whether you’re building furniture, crafting metal art, or working on home improvement projects, a Chop Saw can help you achieve precise cuts with ease.

A chop saw, also known as a cutoff or Miter saw, is a power tool designed for making straight, accurate cuts in various materials, primarily used for woodworking and metalworking applications.

Here’s an overview of chop saws, including types and typical uses:

Types of Chop Saws

a. Miter Saw: A miter saw is a type of chop saw that is versatile and can make angled cuts in addition to straight cuts. It’s commonly used for making miter joints and bevel cuts in woodworking.

b. Compound Miter Saw: This is an advanced version of the Miter Saw that allows you to make both miter and bevel cuts simultaneously. It’s beneficial for projects like crown molding and other complex angles.

c. Sliding Compound Miter Saw: This type of saw adds a sliding feature to the compound miter saw, allowing you to cut wider boards or materials by sliding the blade forward and backward along a rail system.

d. Metal Chop Saw: Designed specifically for cutting metal materials like steel, aluminum, and other non-ferrous metals, these chop saws typically use specialized abrasive or carbide-tipped blades.

e. Abrasive Chop Saw: These chop saws use abrasive wheels to cut through metal and are often used in industrial settings for heavy-duty metal-cutting tasks.

f. Cold Saw: A cold saw uses a circular blade with teeth designed for cutting metal while generating minimal heat. This results in a clean and burr-free cut, making it suitable for precision metalworking.

Typical Uses

a. Woodworking: Chop saws, especially miter saws, are widely used for making straight and angled cuts in wood. They are crucial for framing, molding installation, and furniture making.

b. Carpentry: Carpenters use chop saws to cut wooden boards to specific lengths and angles for constructing various structures, such as decks, fences, and cabinets.

c. Metalworking: Metal chop saws are essential tools in metal fabrication and welding shops, allowing for accurately cutting metal pipes, tubes, and structural components.

d. Construction: Chop saws are frequently used on construction sites for tasks like cutting lumber, molding, and other building materials to size and creating precise angles for framing and trim work.

e. DIY Projects: Hobbyists and DIY enthusiasts find chop saws useful for a wide range of home improvement and crafting projects that involve cutting materials like wood, metal, and plastic.

f. Industrial Applications: In industrial settings, chop saws are used for heavy-duty cutting tasks, such as cutting large steel beams, pipes, and other structural materials.

Miter Saws

Types of Miter Saws

a. Basic Miter Saw: This Miter saw allows you to make basic angle cuts, typically between 0 and 45 degrees. It pivots on a single axis, making it suitable for making straight crosscuts and simple miter cuts.

b. Compound Miter Saw: A compound miter saw not only tilts left and right for miter cuts but also tilts in one direction for bevel cuts. This added feature allows you to make compound angles, making it versatile for a broader range of woodworking and construction tasks.

c. Sliding Compound Miter Saw: The sliding arm allows you to pull the blade forward and backward, increasing the cutting capacity and enabling you to cut wider boards or materials.

d. Dual-Bevel Sliding Compound Miter Saw: This advanced sliding compound miter saw tilts in both left and right directions, making it easier to create complex bevel and miter cuts without flipping the workpiece.

Typical Uses

a. Crosscuts: Miter saws are commonly used for making precise 90-degree crosscuts in boards and lumber. This is a fundamental function for framing, furniture making, and general woodworking.

b. Miter Cuts: Miter saws excel at making angled cuts (miter cuts) at various degrees. This is useful for creating corners, joints, and decorative moldings.

c. Bevel Cuts: With compound and dual-bevel miter saws, you can make bevel cuts, which involve tilting the blade to create angled cuts along the thickness of the material. Bevel cuts are essential for crown molding installation and other decorative work.

D. Compound Cuts: Compound miter saws are perfect for tasks that require both miter and bevel cuts simultaneously, such as creating compound angles for roof rafters or complex trim work.

e. Trim Work: Miter saws are frequently used for cutting trim pieces, baseboards, casings, and crown moldings accurately, ensuring a seamless fit and finish in interior and exterior applications.

f. Cabinet Making: Woodworkers and cabinetmakers rely on miter saws to create precise cuts for assembling cabinets and furniture pieces.

g. Deck Building: Miter saws are valuable tools for angling cuts in decking materials, railing components, and stair treads during deck construction.

H. Flooring Installation: In flooring projects, miter saws help cut boards to the correct lengths and angles for a professional-looking installation.

Mastering Miter Saw Applications: Framing, Crown Molding, and Bevel Cuts”

Framing

Framing is a fundamental aspect of construction and woodworking. It involves creating the skeleton or structural framework of a building or project. A miter saw is an excellent tool for framing due to its precision and efficiency. Here’s how to make the most of your Miter saw for framing projects:

a. Cutting Studs: When framing walls, you’ll often need to cut studs to specific lengths. Set your Miter saw at a 90-degree angle and ensure accurate measurements before cutting to achieve perfectly straight cuts.

b. Angles and Corners: Miter saws can cut precise angles, making them ideal for framing corners. You can easily create clean and tight corner joints by setting your Miter saw to the required angle.

c. Compound Angles: In more complex framing projects, such as hip roofs or bay windows, you may encounter compound angles. A miter saw’s bevel and miter adjustments allow you to make these intricate cuts with ease.

Bevel Cuts

Bevel cuts are essential for creating edges and angles in woodworking projects. A miter saw’s bevel feature allows you to tilt the blade to cut the bevel at various angles. Here’s how to make precise bevel cuts:

a. Adjust the Bevel Angle: Determine the desired bevel angle for your project and adjust the Miter saw accordingly. Most miter saws have clear angle markings for easy setup.

c. Test Cuts: Before making your final bevel cut, it’s a good practice to make test cuts on scrap material to confirm that the angle is correct.

Conclusion

The choice between a chop saw and a miter saw ultimately depends on your needs and preferences. Both tools are valuable additions to a workshop, each with advantages and limitations.

If you require a tool primarily for making quick and accurate crosscuts at various angles, the Miter saw is an excellent choice. Its versatility and ability to make precise miter and bevel cuts make it indispensable for tasks like framing, trim work, and woodworking projects that demand precision and finesse.

On the other hand, if your work primarily involves making straight, 90-degree cuts in materials like metal or wood, a chop saw can be a cost-effective and efficient solution. Its simplicity and power make it a go-to option for cutting metal pipes or heavy-duty construction materials.