Welcome to this beginner-friendly guide on how to sharpen a drill bit with a file. Whether you’re a seasoned DIY enthusiast or just starting to explore the world of tools, knowing how to maintain and sharpen your drill bits can save you time and money.

In this bit-by-bit instructional exercise, we will walk you through revitalizing your dull drill bits using a simple tool you likely already have in your toolbox – a file. So, if you’re ready to breathe new life into your worn-out drill bits, let’s dive into “the most effective method to hone a bore with a record.”

Tools and Materials

A. List of Tools and Materials Required for Sharpening Drill Bits:

Sharpening drill bits requires specific tools and materials to ensure safe and effective results. Here’s what you’ll need:

- Drill Bits in Need of Sharpening: Gather the drill bits that require sharpening. Ensure they are clean and free from debris before starting the sharpening process.

- File: You’ll need a file to sharpen the drill bits. Various types and sizes of files are available, including:

- Flat File: Versatile for general sharpening.

- Triangular File: Ideal for sharpening triangular-shaped flutes.

- Round File: Suited for rounded or curved edges.

- Diamond-Coated File: Efficient for complex materials like metal.

- Safety Equipment: Safety should be a priority while sharpening drill bits. Equip yourself with the following safety gear:

- Safety Glasses: Protect your eyes from sparks, debris, and metal shavings.

- Gloves: Shield your hands from sharp edges and potential injuries.

- Vice or Clamp: Essential for securely holding the drill bit during sharpening.

Preparing the Workspace

A. The Importance of a Clean and Well-Lit Workspace

Creating a clean and well-lit workspace is essential when sharpening drill bits. Here’s why it matters:

- A clutter-free environment ensures ample space to work and move around without obstacles, reducing the risk of mishaps and wounds.

- A well-lit workspace allows you to see the drill bit and sharpening process, crucial for maintaining precision and achieving uniform results.

- Good lighting helps you spot defects, nicks, or irregularities on the drill bit’s cutting edges, allowing you to address them effectively.

- A clean workspace makes identifying and locating your tools easier, ensuring efficiency and preventing frustration.

B. The Need for Securing the Drill Bit to Prevent Accidents

Securing the drill bit is a fundamental safety measure when sharpening. Here’s why it’s crucial:

- A loose or unsecured drill bit can slip or move unexpectedly during sharpening, leading to accidents, injuries, or damage to the bit.

- A vice or clamp provides stability and ensures that the drill bit remains firmly in place, minimizing the risk of it coming into contact with the sharpening tool or your hands.

- A securely held drill bit lets you focus on sharpening without worrying about potential mishaps, enhancing safety and precision.

Before sharpening, always ensure your workspace is clean, well-organized, and well-lit. Use a vice or clamp to secure the drill bit firmly, reducing the likelihood of accidents and promoting a successful and safe sharpening process.

Inspecting the Drill Bit

A. How to Inspect the Drill Bit for Damage and Wear?

Before embarking on the sharpening process, conducting a comprehensive inspection of the drill bit is essential to assess its condition. Start by ensuring the drill bit is clean and devoid of debris or contaminants that could obscure potential defects.

Next, visually examine the drill bit closely under well-lit conditions, particularly the cutting edges, flutes, and shank. Run your fingers gently along these areas to detect subtle imperfections, and consider using a magnifying glass or loupe for a more detailed inspection. This meticulous examination will help identify any damage or wear requiring attention before sharpening.

B. Common Issues to Look for During Inspection

Watch for prevalent issues that could impact the drill bit’s performance during your inspection. Check for chipping or breakage along the cutting edges, as even minor chips can significantly hinder drilling effectiveness.

Assess whether the cutting edges appear dull or rounded, as flat bits may benefit from sharpening. Examine the advantages and flutes for nicks, burrs, or irregularities, as these can affect drilling precision and should be smoothed out. Additionally, scrutinize the wear patterns on the flutes; uneven wear might suggest alignment issues during use.

Lastly, be vigilant for signs of rust or corrosion, particularly if the drill bit has been exposed to moisture. While surface rust can often be removed, deeper decay may necessitate replacement. Conducting this meticulous inspection allows you to make informed decisions regarding whether your drill bit requires sharpening, repair, or replacement, ensuring optimal performance and an extended tool lifespan.

Assessment

A. How to Determine if a Drill Bit Needs Sharpening?

Identifying when a drill bit requires sharpening is essential for ensuring efficient drilling performance. One telltale sign is a noticeable reduction in cutting performance.

If the drill bit struggles to make its way through materials, resulting in slower drilling speeds and increased resistance, it’s likely time for sharpening. Another critical indicator is excessive heat generation during drilling.

If the bit becomes unusually hot, it may signify dullness, which can affect drilling efficiency and risk damaging both the bit and the workpiece. Lastly, watch for any wandering or drifting of the drill bit, even when using proper alignment and technique. Such behavior can signal dull or damaged edges that need attention.

B. The Signs of a Dull or Damaged Drill Bit

Recognizing the signs of a dull or damaged drill bit is crucial for timely maintenance. A primary indication is blunt cutting edges, which can be assessed visually. If the edges appear rounded, worn, or lack the sharpness they once had, the bit likely needs sharpening.

Additionally, inspect the edges for any visible chips or breaks, as even small fragments can significantly impact performance. Run your fingers along the cutting edges and flutes to detect nicks, burrs, or irregularities, which can harm the bit’s effectiveness. Lastly, check for uneven flute wear patterns, which may suggest alignment issues during use.

C. Inspecting the Angle and Edges of the Drill Bit

Pay special attention to the drill bit’s angles and edges as part of your assessment. Ensure that the point angle matches the original specifications for the drill bit type; common point angles include 118 degrees for general-purpose bits and 135 degrees for specialized bits. Examine the cutting edges closely, verifying that they are sharp and free from damage.

In cases where a more detailed inspection is required, using a magnifying glass can be helpful. Regularly conducting these assessments will enable you to promptly address maintenance needs, prolonging your drill bits’ lifespan and maintaining their drilling efficiency.

Sharpening Process

A. Step-by-Step Instructions for Sharpening the Drill Bit with a File

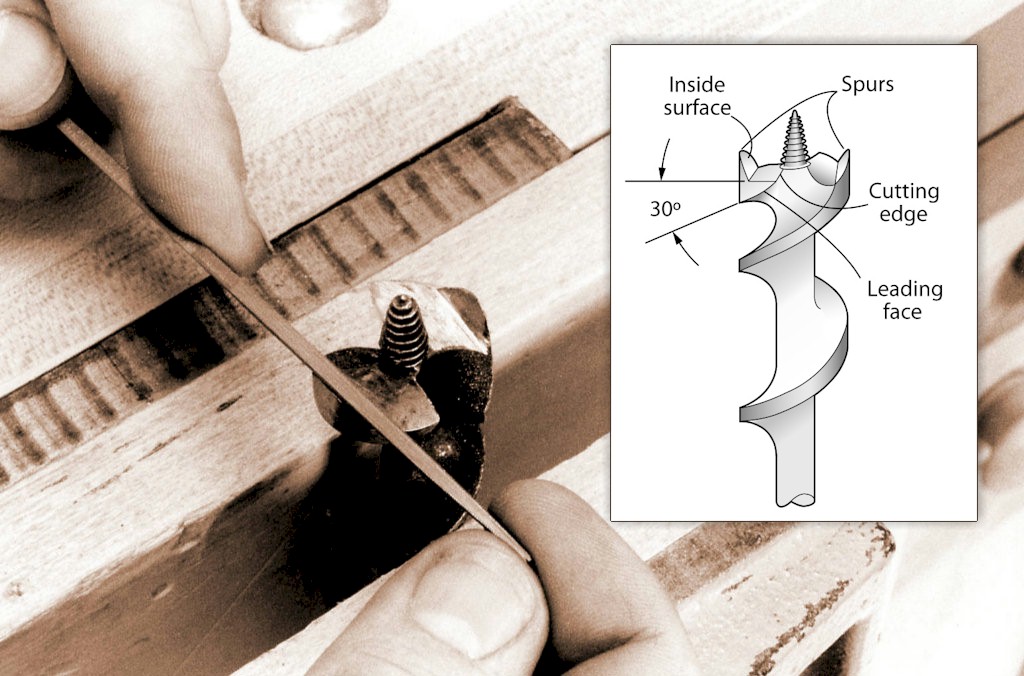

Sharpening a drill bit with a file requires a systematic way to accomplish the best outcomes. To begin, securely clamp the drill bit into a vice or clamp, ensuring that the section to be sharpened is exposed and held firmly in place.

Having the file correctly is crucial; grasp it with both hands and maintain a stable grip. Position the file at a slight angle that matches the existing point angle of the drill bit, typically around 118 degrees for general-purpose bits. Commence filing by gently placing the file against one of the cutting edges and following the contour of the edge.

During this process, it’s essential to maintain a consistent angle to replicate the bit’s original geometry. Use even pressure and execute long, steady strokes to remove uniform material. Continue filling until the cutting edge is sharp and free from nicks or dullness.

B. Tips on Maintaining the Original Angle of the Drill Bit

Preserving the drill bit’s original angle during sharpening is crucial for optimal performance. To achieve this, consistently reference the existing grade of the bit as a guide for filing.

If needed, employ a sharpening jig or guide to help maintain the correct angle throughout the process. Avoid aggressive or uneven filing, which can alter the pitch and affect the bit’s performance.

C. The Importance of Patience and Precision

Patience and precision are fundamental when sharpening drill bits. Hurrying through the cycle can prompt blunders and subpar results. Taking your time to maintain the correct angle, apply even strokes, and achieve a sharp cutting edge is essential.

Precision ensures the bit’s performance is optimized, reducing the need for frequent sharpening and extending longevity. Adhering to these principles will consistently produce sharp and effective drill bits, enhancing your drilling efficiency and accuracy.

Checking for Sharpness

A. How to Test the Sharpness of the Drill Bit?

After sharpening a drill bit, verifying its sharpness before using it for drilling tasks is essential. Here’s how to test the edge:

- Visual Inspection: Begin by visually examining the drill bit’s cutting edges. A sharp bit will have clean, well-defined edges with no visible nicks or dull spots.

- Fingernail Test: Delicately run your fingernail across the cutting edges. A sharp bit will lightly catch your nail, indicating that it has a keen edge.

- Paper Test: Hold a piece of thin cardboard and attempt to make a slight indentation with the drill bit’s cutting edge. A sharp bit should easily penetrate the material without excessive force.

- Start Drilling: Make a test hole if you have a scrap piece of the same material you intend to drill. A sharp bit will start preparing smoothly and cleanly without the need for excessive pressure or generating extreme heat.

B. Signs of a Properly Sharpened Bit

A properly sharpened drill bit exhibits several vital signs:

- Improved Cutting Performance: When using the sharpened bit, you’ll notice that it cuts more efficiently and smoothly through the material. There will be less resistance, reduced heat generation, and cleaner entry into the workpiece.

- Clean Entry Hole: The hole created by a sharpened bit will have a pure entry point with minimal burrs or jagged edges.

- Reduced Heat: Properly sharpened bits generate less heat during drilling, which can extend the lifespan of both the bit and the tool.

- Less Effort Required: Sharpened bits require less force to achieve the desired drilling depth, reducing operator fatigue.

Safety Precautions

A. Importance of Safety Gear and Precautions

Sharpening drill bits involves potential risks, so prioritizing safety is paramount. Here’s why safety gear and precautions are crucial:

- Eye Protection: Wear security glasses with side safeguards to shield your eyes from debris and sparks generated during sharpening.

- Hand Protection: Utilize gloves to safeguard your hands from sharp edges, metal shavings, and potential accidents.

- Ventilation: Work in a well-ventilated area or use a dust extraction system to minimize inhalation of fine metal particles.

- Secure Work Area: Ensure your workspace is clean, organized, and well-lit to reduce the risk of accidents or distractions.

- Tool Maintenance: Keep your files and sharpening equipment in good condition to prevent mishaps and maintain precision.

B. Mentioning Potential Risks and How to Avoid Them

Sharpening drill bits can pose several risks, and understanding how to mitigate them is essential:

- Risk of Eye Injuries: Sparks, debris, or metal shavings can harm your eyes. Wear security glasses with side safeguards to shield your eyes from these hazards.

- Hand Injuries: Sharp drill bit edges and files can cause hand injuries. Wearing gloves is a simple yet effective measure to prevent cuts and abrasions.

- Breathing Hazards: The sharpening process can create fine metal particles that are harmful to inhale. Work in a well-ventilated area or use appropriate dust extraction equipment to minimize exposure.

- Tool Slippage: Ensure that the drill bit is securely clamped or held in place to prevent slipping, which could lead to accidents or damage to the bit.

- Maintain Focus: Sharpening requires concentration. Avoid distractions and maintain focus to reduce the risk of accidents caused by lapses in attention.

By adhering to these safety precautions and understanding the potential risks, you can create a safer working environment when sharpening drill bits, protecting yourself from harm and ensuring a successful sharpening process.

Testing and Fine-Tuning

A. How to Test the Sharpness of the Drill Bit?

After sharpening the drill bit, verifying its sharpness before using it in your projects is essential. Here’s how to test the edge effectively:

- Visual Inspection: Begin by visually examining the drill bit’s cutting edges. A sharp bit will have clean, crisp edges without visible nicks or dull areas.

- Fingernail Test: Tenderly run your fingernail across the cutting edges. A sharp bit will catch your nail slightly, indicating a keen edge. If it slides smoothly without noticing, the bit may require further sharpening.

- Paper Test: Hold a piece of thin cardboard and attempt to make a slight indentation with the drill bit’s cutting edge. A sharp bit should penetrate the material easily with minimal effort.

- Practice Drilling: Make a test hole if you have a scrap piece of the same material you intend to drill. A sharp bit will initiate drilling smoothly and cleanly, requiring less force and generating less heat.

B. Additional Adjustments if Necessary

If the initial testing reveals that the drill bit isn’t as sharp as desired, you may need to make additional adjustments:

- Touch-Up Sharpening: If the bit isn’t as sharp as needed, repeat the sharpening process, paying careful attention to maintain the correct angle and applying steady, even strokes.

- Recheck Angles: Ensure you maintain the drill bit’s original point angle throughout the sharpening process. Any deviations can affect sharpness.

- Test Again: After making adjustments, retest the sharpness using the earlier methods. Continue the process until you achieve the desired level of sensitivity.

Testing the bit’s sharpness and making any necessary fine-tuning adjustments will ensure that your drill bit is in optimal condition for efficient and precise drilling tasks.

Maintaining Sharpness

A. Tips on How to Keep Drill Bits Sharp for Longer

To extend the lifespan and maintain the sharpness of your drill bits, follow these essential tips:

- Cleaning After Use: After each use, thoroughly clean the drill bit to remove debris, shavings, or material residues. This prevents the accumulation of dulling agents and corrosion, helping to preserve the cutting edges.

- Avoiding Excessive Heat: Avoid applying excessive pressure or speed while drilling, as this can generate extreme heat that may damage the cutting edges. Use the appropriate drill speed for the material being worked on and let the bit do the work with minimal force.

B. Occasional Need for Professional Sharpening

Despite your best efforts at maintenance, drill bits may eventually require professional sharpening. Professional sharpening services have specialized equipment and expertise to restore bits to their original sharpness.

Signs that it’s time for professional sharpening include significant dullness, severe damage, or an inability to achieve desired results even after DIY sharpening attempts. Regular maintenance can delay professional sharpening, but it’s a valuable option when extensive restoration is necessary.

Conclusion

Learning how to sharpen a drill bit with a file is valuable for anyone who regularly uses drills. It saves money by prolonging the life of your drill bits and ensures that your drilling projects are more efficient and effective.

Following the means framed in this aide, you can achieve a sharp and precise drill bit that will make your drilling tasks more accessible and more accurate.

The effort you invest in learning this skill will pay off in the long run, as you’ll have the confidence and ability to maintain your drill bits in top condition, resulting in cleaner holes and smoother operations.