Would you like to know if a 6 amp reciprocating saw powerful enough punch for your cutting needs? The power tool market can be a labyrinth of specifications and jargon, making it challenging to discern what makes a saw formidable.

Whether you’re a seasoned DIY enthusiast or a novice looking to dive into the world of cutting and demolition, understanding the capabilities of a 6 amp reciprocating saw is crucial to making informed decisions.

Let’s explore the realm of these versatile cutting machines and uncover whether a 6 amp reciprocating saw is, indeed, powerful enough to handle your projects with ease.

Understanding Power Requirements

Understanding the power requirements for a reciprocating saw is crucial to maximize its performance and efficiency. Power in reciprocating saws is typically measured in amperage (amps), with voltage also playing a significant role. Amperage represents the electrical current flowing through the saw’s motor, while voltage is the electrical force driving this current.

Combining these factors provides the wattage, a holistic measure of power. The relationship between power and performance in a reciprocating saw is multifaceted.

Adequate power increases cutting capacity, enabling the tool to easily tackle thicker and more complex materials. It also influences cutting speed and efficiency, ensuring consistent performance under various loads.

However, power levels can affect heat generation within the motor, impacting the saw’s durability over time. When choosing a reciprocating saw, it’s essential to match its power to the specific task, considering factors like the material’s type and thickness.

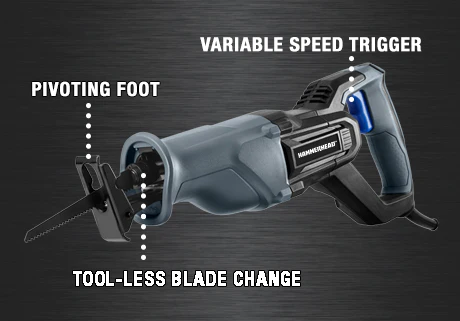

Blade selection is crucial in complementing the saw’s power for optimal results. Balancing power requirements with other features such as weight, portability, power source (corded or cordless), and cost is vital to making an informed choice.

Applications of a 6-Amp Reciprocating Saw

A 6-amp reciprocating saw, with its moderate power rating, finds a range of applications across light to medium-duty tasks. Understanding its capabilities helps users make the most of this tool. Here are some typical

Cutting Thin Materials: This type of reciprocating saw is well-suited for cutting thin materials such as plywood, plastic, and lightweight metals. It can make precise and controlled cuts, making it ideal for DIY projects and crafting.

Pruning Small Branches: When equipped with the appropriate pruning blade, a 6-amp reciprocating saw can be used for trimming small branches and shrubs in the garden. It offers better control than larger and more powerful chainsaws.

Cutting Wood Studs: For light carpentry work, such as framing or installing shelves, a 6-amp reciprocating saw can efficiently cut through wood studs and similar materials. It’s portable and handy for various home improvement tasks.

Demolition Work on Small Structures: When it comes to minor demolition tasks like removing drywall, small partitions, or cutting through nails and screws in renovation projects, this saw can be a valuable tool.

Plumbing and Electrical Work: Cutting through plastic pipes, copper tubing, or electrical conduits is another application where a 6-amp reciprocating saw can be advantageous. Its versatility can assist in making clean cuts.

Auto Body Repairs: This saw can be used for cutting and shaping sheet metal or fiberglass in automotive repair and restoration. It offers more control than larger tools, making it suitable for precision work.

Hobby and Craft Projects: DIY enthusiasts and hobbyists often use this type of saw for various projects, such as creating intricate wooden designs, model building, and crafting.

Factors Influencing Power Requirements

Several factors influence the power requirements of a reciprocating saw, dictating the level of power needed to complete a given task effectively. Understanding these factors is crucial for selecting the right tool for the job and ensuring optimal performance. Here are the key factors that influence power requirements:

Material Type: The type of material you intend to cut significantly affects the power requirements. For instance, cutting through softwood like pine requires less power than dense hardwoods, metal, or masonry. Different materials offer varying resistance levels to the saw blade, demanding more or less power.

Material Thickness: Thicker materials generally require more power to cut through efficiently. Thin materials like thin plywood or plastic may demand less power than cutting through thick lumber, metal pipes, or concrete.

Blade Type and Condition: The type and condition of the saw blade play a crucial role in power requirements. A sharp and appropriate blade can reduce the strain on the motor. In contrast, a dull or improper blade might demand more power to achieve the same cutting results.

Frequency of Use: How often you use the reciprocating saw can influence the power requirements. For occasional or light use, a lower-amp saw may suffice. However, frequent and prolonged use, especially in demanding applications, may necessitate a higher-amp saw to prevent overheating and premature motor wear.

User Skill and Technique: The skill and technique of the operator also impact power requirements. Through proper control and technique, skilled users can achieve more efficient cuts with less powerful saws. Conversely, less experienced users benefit from more power to compensate for their technique.

Cutting Speed: The desired cutting speed can determine power needs. Faster cutting often requires more power to maintain the speed and efficiency of the saw. Slower cutting speeds are acceptable for precision work and require less power.

Voltage Supply: If you use a corded reciprocating saw, the voltage supply also plays a role. Saws with higher voltage ratings generally offer more power. However, it’s essential to consider the available power source and ensure it matches the saw’s requirements.

Cutting capacity of 6amp reciprocating saw

The cutting capacity of a 6-amp reciprocating saw depends on various factors, including the type of material you are cutting, the thickness of the material, the quality of the blade, and the saw’s design and power. While a 6-amp reciprocating saw is generally considered a light to medium-duty tool, here are some guidelines for its cutting capacity:

Wood: A 6-amp reciprocating saw can typically handle wood-cutting tasks effectively. It can easily cut through standard dimensional lumber, plywood, and similar materials. However, it may need help with dense hardwoods or extremely thick lumber.

Metal: When cutting metal, a 6-amp reciprocating saw can work well with thin metals like sheet metal, aluminum, or thin steel pipes. For thicker or harder metals, such as thick steel beams or cast iron, you may experience reduced cutting efficiency.

Plastic: Cutting plastic materials, such as PVC pipes or plastic sheets, is well within the capacity of a 6-amp reciprocating saw. It offers precise control for such tasks.

Pruning: If you intend to use the saw for pruning tree branches, it can effectively handle small to medium-sized branches. However, it may struggle with very thick or hard branches.

Demolition: For light demolition work, like removing drywall, small partitions, or cutting through nails and screws, a 6-amp reciprocating saw is suitable. There may be better choices for extensive demolition tasks on larger structures.

Precision Work: This type of reciprocating saw can excel in precision work, such as crafting, model building, or making delicate cuts in woodworking. Its lower power allows for better control in these situations.

Advantages of a 6-Amp Reciprocating Saw

A 6-amp reciprocating saw, while not the most powerful option available, offers several advantages that make it a valuable tool for specific applications. Understanding these advantages can help users make informed choices when selecting a reciprocating saw for their needs. Here are the key advantages of a 6-amp reciprocating saw:

Lightweight and Maneuverable: 6-amp reciprocating saws are typically more compact and lightweight than higher-amp models. This makes them easy to handle and maneuver, reducing user fatigue during extended use or when working in tight spaces.

Affordability: These saws are often more budget-friendly than their higher-amp counterparts. This makes them attractive for DIY enthusiasts, occasional users, or those looking for a cost-effective tool for specific tasks.

Suitable for DIY and Occasional Use: A 6-amp reciprocating saw is well-suited for do-it-yourself projects and occasional home improvement tasks. It can handle various cutting jobs around the house without needing a high-powered, professional-grade tool.

Precise Control: The lower power level allows for more precise and controlled cuts, which can be essential for tasks that require accuracy, such as crafting or making delicate cuts in woodworking.

Less Vibration and Noise: Lower-amp reciprocating saws produce less vibration and noise than their higher-amp counterparts. This can contribute to a more comfortable and less disruptive working environment.

Reduced Risk of Overheating: Since 6-amp reciprocating saws are less powerful than larger models, they are less prone to overheating during extended use on light to medium-duty tasks. This can extend the tool’s lifespan and minimize maintenance needs.

Portability: The compact size and reduced weight of a 6-amp reciprocating saw make it easy to transport to job sites or move around within a workspace. This portability can be advantageous for contractors and DIYers alike.

Versatility: While unsuitable for heavy-duty tasks, these saws can still handle various materials, including wood, plastic, thin metal, and PVC piping. This versatility makes them valuable for various applications.

Easier for Beginners: Beginners and less-experienced users may find a 6-amp reciprocating saw more forgiving to work with due to its lower power, which can result in fewer mistakes and more controlled cuts.

Disadvantages of a 6-Amp Reciprocating Saw

While a 6-amp reciprocating saw has its advantages, it also comes with certain limitations and disadvantages that users should be aware of. Understanding these drawbacks is essential for making informed decisions when choosing the right tool for specific applications. Here are the key disadvantages of a 6-amp reciprocating saw:

Limited Power for Heavy-Duty Tasks: One of the most significant disadvantages of a 6-amp reciprocating saw is its limited power. It may need help to cut through thick or dense materials, such as hardwoods, thick metal, or masonry. Attempting heavy-duty tasks with this tool can lead to slow cutting speeds, overheating, and premature wear on the motor.

Slower Cutting Speeds: Due to its lower power output, a 6-amp saw often operates at slower cutting speeds than higher-amp models. This can make it less efficient for tasks that require rapid cutting or extensive material removal.

Less Durability Under Heavy Use: Continuous or frequent use of demanding materials can increase wear and tear on the saw’s components. A 6-amp reciprocating saw may not withstand heavy use as well as higher-amp, industrial-grade models, potentially resulting in a shorter tool lifespan.

Inadequate for Thick Materials: When dealing with thick materials, such as thick lumber or steel beams, a 6-amp saw may need help to make efficient cuts. This can lead to frustration and the need for multiple passes, affecting the quality of the cuts.

Limited Blade Choices: Some high-performance blades, designed for heavy-duty tasks, may not be compatible with 6-amp saws due to their lower power. Users may have to rely on standard or lighter-duty blades, which might limit their cutting options.

Potential for Motor Overheating: Prolonged use on demanding tasks or pushing the saw beyond its capabilities can lead to motor overheating. Overheating can reduce the tool’s lifespan and necessitate cooling breaks during work.

Less Versatility for Professional Use: While suitable for DIY and occasional use, a 6-amp reciprocating saw may need to meet the requirements of professional contractors who frequently tackle heavy-duty construction or demolition tasks.

Limited Depth of Cut: Thick materials may require deeper cuts, which a 6-amp saw may need help to achieve efficiently. This limitation can affect the versatility of the tool for specific applications.

Factors influencing power needs

Several factors influence the power needs of various tools, including power tools like reciprocating saws. Understanding these factors is crucial for choosing the right tool for a specific task and ensuring optimal performance. Here are the key factors that influence power needs:

Material Type: The type of material you’re working with is a significant factor. Harder materials like hardwoods or metals require more power to cut efficiently than softer materials like pine or plastic.

Material Thickness: Thicker materials demand more power. The depth of the cut directly affects the resistance encountered by the blade.

Blade Type and Condition: The type and condition of the cutting blade play a crucial role in power requirements. A sharp and appropriate blade reduces the strain on the motor. In contrast, a dull or incorrect blade may demand more power to achieve the same cutting results.

Cutting Speed: The desired cutting speed can affect power needs. Faster cutting often demands more power to maintain the speed and efficiency of the tool. Slower cutting speeds are acceptable for precision work and require less power.

Frequency of Use: How often you use the tool influences power needs. For occasional or light use, a lower-powered tool may suffice. Frequent and prolonged use, especially in demanding applications, may necessitate a higher-powered tool to prevent overheating and premature wear.

User Skill and Technique: The operator’s skill and technique can impact power requirements. Through proper control and technique, skilled users may achieve more efficient cuts with less powerful tools. In contrast, less experienced users might benefit from more power to compensate for their technique.

Voltage Supply: In the case of corded tools, the available voltage supply also plays a role. Tools with higher voltage ratings generally offer more power. However, it’s essential to consider the available power source and ensure it matches the tool’s requirements.

Tool Design and Efficiency: The efficiency and design of the tool’s motor and mechanics can affect power needs. Well-designed tools can maximize available power and deliver more efficient cutting performance.

Environmental Conditions: Extreme environmental conditions, such as high temperatures or high humidity, can affect the performance of power tools. In such conditions, tools may require additional power to maintain performance.

Safety Considerations: Ensuring the operator’s and the tool’s safety can impact power needs. For example, some tools may include safety features like blade brakes or stall protection, which can affect power usage.

Conclusion

A 6-amp reciprocating saw is a versatile tool that finds its place in light to medium-duty applications. Its advantages include affordability, portability, and suitability. However, its limitations include reduced cutting capacity for thick or dense materials and slower cutting speeds.

Understanding the tool’s capabilities and matching it to the specific task and material is essential to maximize its performance. Users should consider material type, thickness, blade selection, and skill level when using a 6-amp reciprocating saw. Higher-amp models may be more appropriate for heavy-duty tasks or frequent professional use.