It’s hard to imagine a time when cutting down trees wasn’t as simple as firing a chainsaw. The chainsaw development revolutionized the logging industry and made cutting trees faster and more efficient.

But what did the first chainsaw look like? We’ll journey back in time to explore the origins of this powerful tool and discover what the first chainsaw looked like.

Invented to Help with Childbirth

The first chainsaw was not invented to cut wood. The first chainsaw was invented to help with childbirth. John Aitken and Jeffrey invented the first chainsaw in the 18th century.

Childbirth was a difficult and dangerous process then, and many women died due to complications during delivery. Aitken and Jeffrey believed a chainsaw could make the delivery process easier and safer.

The first chainsaws were not powered by gasoline or electricity but by hand. They consisted of a long, serrated chain with handles on either end.

The chain was wrapped around the pubic bone of the woman in labor, and the two handles were pulled back and forth to cut through the bone. The idea was that by cutting the pubic bone, the baby would have more room to pass through the birth canal.

While the idea behind the first chainsaw was noble, it was ineffective. The chainsaw was difficult to use and often caused more harm than good. It was also extremely painful for the woman in labor, and many refused to use it.

In 1926, Andreas Stihl invented the first gasoline-powered chainsaw, revolutionizing the logging industry. The chainsaw quickly became a popular tool for cutting down trees and harvesting wood, and its use continued to expand into other industries.

Today, chainsaws come in various shapes and sizes and are used for various tasks. They are powered by electricity, gasoline, or battery. While they are no longer used for childbirth, the chainsaw remains an important tool for many industries, including forestry, construction, and landscaping.

Advancements to the Symphysiotomy

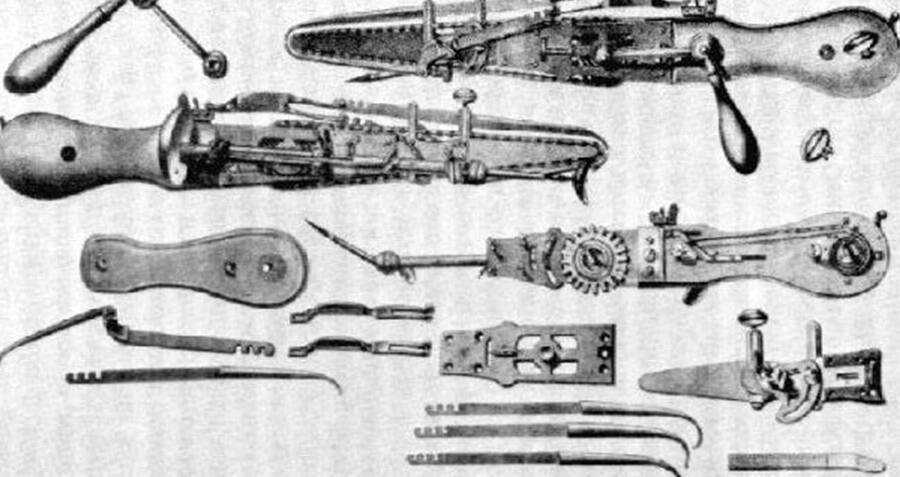

In 1785, Scottish obstetricians John Aitken and James Jeffrey made significant advancements to the symphysiotomy method of childbirth using a tool now known as the Aitkens flexible chainsaw. In contrast to the rigid saws and sharp knives commonly used for the procedure, the flexible chainsaw caused less trauma to the surrounding tissues.

The Aitkens flexible chainsaw had handles shaped like teardrops on both ends and a fine link chain with serrations because one of the handles could be taken off. Afterward, the surgeon would “see” through the pelvic bone more quickly and precisely by moving their hands back and forth.

While the symphysiotomy method fell out of favor at the turn of the century, flexible chainsaws like the Gigli wire are still used today in some medical procedures where precision and control are crucial.

Birthing Babies in the Olden Days

Childbirth has been a part of human life since the beginning of time. Still, before modern medical advancements like anesthesia, antibiotics, and hygiene practices, it was an especially challenging and risky experience.

In the late 1700s, French doctor Jean-René Sigault proposed a solution to this problem by surgically separating the pelvic joint to create a larger opening in the pelvis. His idea was inspired by the writings of French surgeon Severin Pineau, who described the “diastasis of the pubis” in a pregnant woman who was hanged.

In October 1777, Sigault performed the first symphysiotomy on a patient with a contracted pelvis due to rickets, successfully saving the lives of both the mother and child. This procedure soon became routine for women experiencing obstructed labor and offered a viable alternative to the high-risk cesarean section.

Bernhard Heine’s Version of the First Chainsaw

The invention of the chain osteotome by Bernhard Heine in 1830 revolutionized surgical techniques and allowed for more precise and less traumatic bone surgery.

The osteotome was designed similarly to modern chainsaws, with teeth on the exterior and grooves on the inside. It had a hand crank and could cut through bone quickly and efficiently, saving patients from using a hammer and chisel or a common amputation saw.

The osteotome was customizable and ideal for fragile medical procedures like craniotomies. Notwithstanding, it was costly and expected a lot of expertise to utilize.

Heine was one of the few who knew how to use an osteotome.Nonetheless, the osteotome remains a significant innovation in surgical technology and is highly valued among collectors of antique surgical instruments.

Andreas Stihl Invents the Electric Chainsaw

In 1897, designer and naturalist John Muir concocted a huge mechanical machine that gauged many pounds and required a crane. However, due to its impracticality, it failed to gain commercial success. In 1905, Samuel J.

Bens, a San Francisco-based logger, applied for a patent for his “endless-chain saw,” which was also rather large and required more than one user, making it impractical. Over a decade later, James Shand from Canada patented the first portable chainsaw, which was still bulky.

In the 1950s, the first one-person chainsaw was produced; this cleared the path for modern chainsaws, which have continued to evolve. Today, chainsaws are widely used in forestry, landscaping, construction, and many other industries.

The Original Uses of Chainsaws

Johann Heine invented the chain osteotome, which was used for surgeries that required cutting through bone, such as amputations. Heine’s invention was a significant improvement over the traditional hammer and chisel method as it simplified the procedure and improved the results.

The medical chainsaw became popular, and Heine won a prestigious award in France for his invention, and he was even invited to Russia to demonstrate the tool. Manufacturers in France and New York began making the surgical instrument en masse.

However, the chainsaw was not the best solution to an age-old problem in childbirth, and sterile surgical environments, anesthesia, and access to more advanced medical care saved more lives in childbirth.

In 1905, Samuel J. Bens realized that the medical chainsaw could be used for cutting down redwood trees even better than it could be used for cutting bone. He filed a patent for the first recognizably modern chainsaw, which began the evolution of chainsaws for industrial and commercial use.

The First Wood Cutting Chainsaw

While the first chainsaw was invented to help with childbirth, it wasn’t until the early 20th century that it was adapted for use in the logging industry. In 1926, Andreas Stihl invented the first gasoline-powered chainsaw, revolutionizing the logging industry.

The first wood-cutting chainsaws were heavy and unwieldy, weighing over 100 pounds. They were difficult to start and required much physical strength to operate. However, they were still much faster and more efficient than the traditional hand-sawing and axe-cutting methods.

Lightweight materials were introduced, making the chainsaw easier to handle and operate. Advances in engine technology made the chainsaw more powerful and efficient, allowing loggers to cut through trees more quickly and easily.

Today, chainsaws come in various shapes and sizes, from small handheld models to large industrial machines. They are used for various tasks, from cutting down trees to trimming branches and cutting firewood. While the basic design of the chainsaw has remained the same, advances in technology continue to make the chainsaw a more efficient and versatile tool for many industries.

Modern Chainsaws

Advancements in chainsaw technology

Advancements in chainsaw technology have revolutionized the logging industry, making the chainsaw a more efficient and safer tool for cutting wood. Anti-vibration technology has reduced the vibration the operator feels, making it easier to use and reducing the risk of injury. Automatic oiling systems continuously lubricate the chain while it is in use, reducing wear and tear and prolonging the life of the chain.

Electronic ignition has made starting the chainsaw easier and more reliable. Safety features like chain brakes, anti-kickback features, and throttle interlocks help prevent accidents and keep the operator safe. Lightweight materials have made modern chainsaws much lighter than their predecessors, making them more comfortable for extended periods.

Advances in environmental considerations have allowed modern chainsaws to be more environmentally friendly, producing less emissions, using less fuel, and being more efficient, reducing waste and energy consumption. As technology advances, chainsaws will evolve, becoming even safer, more efficient, and more environmentally friendly.

Anti-vibration technology

In the past, chainsaw operators had to endure the vibrations produced by the machine, leading to long-term health problems. However, with the introduction of anti-vibration technology, chainsaws have become much easier and safer to use.

Anti-vibration technology in chainsaws reduces the vibration transferred to the operator’s hands and arms. These features absorb and dissipate the vibration the chainsaw produces, making it much more comfortable and safe to use for extended periods. The benefits of anti-vibration technology are numerous.

It improves the operator’s comfort, making it easier to use the chainsaw for extended periods without experiencing discomfort or fatigue. Additionally, it improves the accuracy of the cuts, as the reduced vibration makes it easier to control the chainsaw.

Today, many chainsaws come equipped with anti-vibration technology as a standard feature.

Safety features

Modern chainsaws have various safety features designed to protect the operator and prevent accidents. Features found in modern chainsaws

Chain brake

The chain brake is one of a chainsaw’s most important safety features. It is made to stop the chain from moving in the event of kickback, which can occur when it hits a hard object or encounters resistance. The chain brake is typically activated either manually or automatically by a sensor.

Anti-kickback features

Anti-kickback features are designed to prevent the chainsaw from “bouncing back” or “jumping” when it encounters resistance. This feature typically involves a guard at the bar’s tip that helps reduce the likelihood of kickback.

Throttle interlock

A throttle interlock is a safety feature that prevents the throttle from being accidentally activated. This feature is typically located on the chainsaw handle and must be engaged before the throttle can be activated.

Chain catcher

A chain catcher is a safety feature designed to stop the chain if it breaks or derails. It typically consists of a metal plate at the bar’s base, which catches the chain and prevents it from flying off.

Bar tip guard

A bar tip guard is a safety feature that protects the bar’s tip from damage and prevents the chain from accidentally hitting objects.

Safety switch

Some chainsaws come equipped with a safety switch that stops the chainsaw from being started accidentally. This feature is typically located on the chainsaw handle and must be engaged before the chainsaw can be started.

Automatic oiling systems

In the past, operators had to manually lubricate the chain with oil, which could be time-consuming and potentially dangerous. However, chainsaws have become much easier to use and maintain with automatic oiling systems.

Automatic oiling systems in chainsaws automatically lubricate the chain while it is in use. The system typically consists of a small oil pump driven by the engine and a reservoir of oil stored in the chainsaw’s body. The oil pump delivers oil to the chain as it rotates, ensuring it is constantly lubricated and reducing wear and tear.

They ensure that the chain is always properly lubricated, which reduces wear and tear and prolongs the life of the chain. They also reduce the maintenance required, as operators no longer need to manually lubricate the chain.

Additionally, they make the chainsaw safer to use, as operators no longer need to remove the bar and chain to manually lubricate the chain, which can be a potentially dangerous process.

However, ensuring the oil reservoir is properly filled before using the chainsaw is important, as low oil levels can lead to poor lubrication and premature wear and tear.

Environmentally-friendly chainsaws

- Battery-powered chainsaws

- Ethanol-powered chainsaws

Battery-powered chainsaws

Recently, battery-powered chainsaws have emerged as a popular alternative to traditional gas-powered chainsaws. Battery-powered chainsaws offer several advantages over their gas-powered counterparts, including quieter operation, lower maintenance requirements, and zero emissions.

Battery-powered chainsaws are powered by rechargeable lithium-ion batteries, providing several hours of run time on a single charge.

One of the biggest advantages of battery-powered chainsaws is their quiet operation. Unlike gas-powered chainsaws, which can be loud and disruptive, battery-powered chainsaws produce very little noise, making them ideal for use in urban or suburban areas where noise restrictions may exist.

Another advantage of battery-powered chainsaws is their low maintenance requirements. Unlike gas-powered chainsaws, which require regular oil changes, spark plug replacements, and air filter cleanings, battery-powered chainsaws require very little maintenance beyond the occasional sharpening of the chain. Battery-powered chainsaws produce zero emissions, making them an eco-friendly alternative to gas-powered chainsaws.

While battery-powered chainsaws may not be suitable for all applications, they are a great option for those looking for a lightweight, quiet, and eco-friendly alternative to traditional gas-powered chainsaws.

Ethanol-powered chainsaws

Ethanol can power small engines, such as those found in chainsaws. However, ethanol-powered chainsaws have advantages and disadvantages that operators should know before choosing this type of chainsaw. One of the primary advantages of ethanol-powered chainsaws is that ethanol is a renewable and domestically produced fuel.

Another advantage of ethanol-powered chainsaws is that ethanol is less expensive than gasoline.

In addition, ethanol can be less energy-dense than gasoline, meaning it may not provide as much power or run time as a gasoline-powered chainsaw. Ethanol may also require more frequent fueling, as it burns faster than gasoline.

There are concerns about the compatibility of ethanol with certain types of fuel lines and other components in the chainsaw. Some manufacturers caution against using ethanol in their chainsaws, while others may recommend using a fuel stabilizer or other additives to reduce the risk of damage.

Ethanol-powered chainsaws offer advantages over gasoline-powered chainsaws, including lower costs and reduced emissions. However, they also have some disadvantages, including concerns about corrosion and compatibility with certain components.

Different Types of Chainsaws for Different Needs

Chainsaws come in many shapes and sizes, each designed for a specific purpose. Here are three different types of chainsaws, each with unique features and benefits.

Lightweight Chainsaws:

Lightweight chainsaws are designed for homeowners and others who need a chainsaw for occasional use. These chainsaws are typically compact and easy to handle, with engines that range from 25cc to 40cc.

They are ideal for trimming branches, cutting small trees, and other light-duty tasks. Lightweight chainsaws are often electric or battery-powered, making them even easier to handle and reducing the need for frequent maintenance.

High-Performance Chainsaws:

High-performance chainsaws are designed for professionals and others needing heavy-duty chainsaws. These chainsaws have more powerful engines, ranging from 50cc to over 100cc, and longer bars and chains.

They are ideal for felling large trees, cutting firewood, and other demanding tasks. High-performance chainsaws are often gas-powered and may include anti-vibration technology, automatic oiling systems, and quick-release air filters for easier maintenance.

Professional-Grade Chainsaws:

Professional-grade chainsaws are designed for loggers, arborists, and others who need a chainsaw for daily use in challenging environments. These chainsaws are built to withstand the rigors of heavy use and feature powerful engines, typically over 100cc, and long bars and chains.

They may also include advanced anti-vibration technology, automatic oiling systems, and professional-grade air filtration systems. Professional-grade chainsaws are often gas-powered, although some electric models are available for specialized applications.

FAQs (What did the first chainsaw look like?)

What was the first chainsaw invented for?

The first chainsaw was not invented for industrial use but for medical purposes. Johann Heine, a German orthopedist, invented the “chain osteotome” in the mid-19th century, which was used to cut through bone during surgeries.

When was the first chainsaw invented?

Johann Heine invented the first chainsaw in the mid-19th century, but it was not used for industrial or commercial purposes then.

What did the first chainsaw look like?

The first chainsaw did not resemble modern chainsaws. It was a large, handheld machine that weighed several hundred pounds and required a crane for operation. It had a chain with cutting teeth, similar to modern chainsaws, but it was attached to a large mechanical machine.

Who invented the first portable chainsaw?

Canadian James Shand invented the first portable chainsaw in the early 20th century. However, it was still bulky and required more than one user to operate.

When was the first electric chainsaw invented?

The first electric chainsaw was patented in 1926 by German mechanic Andreas Stihl. However, it still required more than one person to operate.

What was the first gas-powered chainsaw?

Andreas Stihl also patented the first gas-powered chainsaw in 1929, an improvement over the electric chainsaw, but it still required more than one person to operate.

Who invented the first one-person chainsaw?

The first one-person chainsaw was not invented until the 1950s. Various manufacturers, including Husqvarna and Stihl, created it and revolutionized the industry by making it easier and safer for one person to operate a chainsaw.

Did the first chainsaw have safety features?

The first chainsaw did not have the safety features that modern chainsaws have. The first chainsaw lacked safety guards to protect the user from the cutting chain, making it a dangerous operation tool.