When it comes to woodworking and the art of drilling precision holes, having the right tools at your disposal can make all the difference in the world. One such tool that often sparks curiosity is the Brad Point drill bit.

This specialized instrument plays a pivotal role in woodworking and various other applications, offering a unique set of features that sets it apart from the run-of-the-mill drill bits. In this exploration, we’ll explore (What is a Brad Point Drill Bit Used For), and unraveling its purpose and shedding light on how it can elevate your woodworking and hole-drilling projects.

Understanding Brad Point Drill Bits

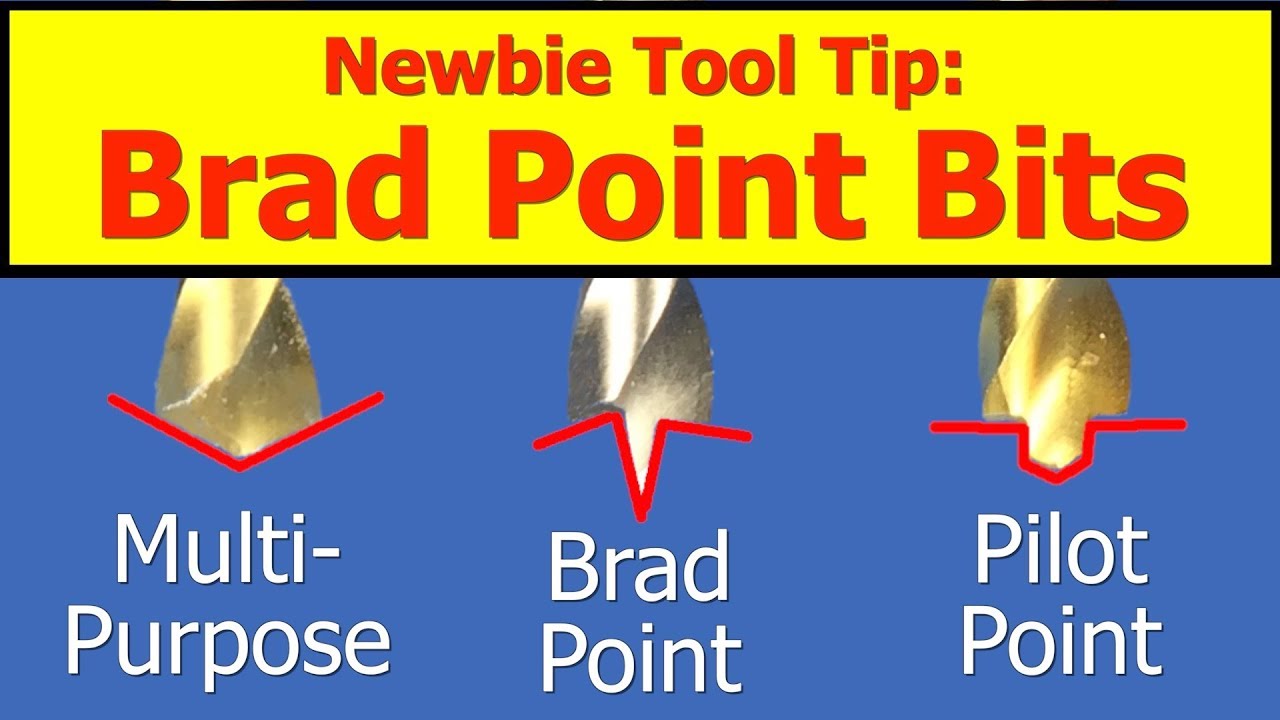

Brad Point drill bits, also known as brad-point bits or doweling bits, belong to a distinguished category of woodworking drill bits designed to craft pristine and precise holes in wood. They are easily distinguishable by their unmistakable pointed tip, adorned with spurs on either side.

Pointed Tip: The hallmark feature of a Brad Point drill bit is its sharp and pinpointed tip. This tip serves the critical function of accurately locating the center of the hole you intend to drill, making it the go-to choose for tasks where hole placement needs to be nothing short of exact.

Spurs: On both sides of the pointed tip, Brad Point drill bits proudly flaunt spurs or cutting edges. These spurs function as miniature blades, meticulously scoring the wood fibers and fashioning a crisp and clean entry point for the drill bit. Furthermore, they play a pivotal role in minimizing “walking” or any undesired drifting of the bit when you commence drilling.

Lip and Cutting Edges: Nestled behind the spurs, you’ll find a lip or cutting edge on Brad-point bits. This component shears the wood fibers as the bit penetrates the material, thereby minimizing tear-out and gifting you with a neat exit hole on the opposite side of your workpiece.

Flutes: Brad Point drill bits usually flaunt two flutes that traverse the bit’s length. As you engage in drilling, these flutes tirelessly remove wood chips and debris from the hole, ensuring the drilling process remains efficient and preventing any unwanted overheating.

Diameter Variety: Brad Point drill bits come in a multitude of diameters, tailored to cater to various drilling needs. They are frequently enlisted for drilling dowel holes, creating impeccable holes for screws, and various other precision-driven woodworking tasks.

Woodworking Applications

Brad-point bits ascend to the zenith of their prowess in woodworking applications that place a premium on precision and pristine hole edges.

They’re the trusted ally for tasks such as:

- Dowel Joints: When the goal is to create holes for dowel joints that demand a snug fit and a bond that’s as strong as it gets, Brad-point bits take center stage.

- Joinery Techniques: The realm of joinery, replete with mortise and tenon joints, finds its perfect match in these bits. They’re the architects behind the precise holes that tenons call home, ensuring a connection between wooden pieces that’s unyielding.

- Cabinetmaking: In the world of cabinetmaking, where every detail matters, Brad-point bits are often summoned to drill holes for concealed hinges, shelf pins, and other hardware components. The clean entry and exit holes add a dash of professionalism to the final product.

- Furniture Making: Craftsmen and women rely on these bits for drilling holes for wooden plugs or buttons that artfully conceal screws, the very essence of assembling furniture with flair.

- Decorative Touches: Whether it’s inlays, decorative pegs, or intricate accents, Brad Point drill bits possess the finesse required to bring out the artistry in woodworking.

- Woodturning: Woodturners employ these bits to bore holes for the installation of centers or inlay work in turned wooden marvels like bowls, vases, and spindles.

- Flute-making: The world of music isn’t left untouched. Musicians and flute makers turn to Brad-point bits to craft precise and pristine boreholes inside wooden flutes, recorders, and various other musical instruments.

- Staircase Construction: In the realm of staircase construction, Brad Point drill bits are entrusted with the creation of precise holes for spindles and balusters, a task that ensures both security and aesthetics in the staircase assembly.

- Shelving Systems: When the quest is for the perfect custom shelving system, these bits step up to drill holes for shelf support pins, guaranteeing that the shelves stand tall and level.

- Wooden Toys: Crafters and toy makers tap into their prowess to create holes for axles, wheels, and other components in wooden toys, ensuring a sturdy and safe construction.

- Architectural Woodwork: In the domain of architectural woodwork, where precision and aesthetics reign supreme, Brad Point drill bits take on the role of drilling holes for stair railings, newel posts, and intricate wood trim.

- Luthiery: The realm of musical instrument crafting, known as luthiery, witnesses the use of Brad-point bits to craft precise holes for tuning pegs, bridge pins, and other components that wield influence over the instrument’s tone and playability.

Features and Components of a Brad Point Drill Bit

Brad Point drill bits, crafted with woodworking applications in mind, boast a set of features and components that differentiate them from standard twist drill bits.

Here’s a closer look at these distinguishing elements:

Pointed Tip: The most conspicuous feature of a Brad Point drill bit is its sharp, pinpointed tip. This tip is fashioned to precisely locate the center of the hole to be drilled, obviating the need for a center punch or additional markings on your workpiece.

Spurs or Cutting Spurs: Flanking the pointed tip, Brad-point bits are adorned with spurs or cutting spurs. These spurs serve dual roles:

- They meticulously score the wood fibers at the hole’s periphery, giving birth to a pristine and crisp entry point for the drill bit.

- They stand as steadfast guardians against the bit’s tendency to wander or “walk,” ensuring that the hole starts precisely where you intended it to.

Cutting Lips: Dwelling just behind the spurs, Brad Point bits feature cutting lips. These lips bear the responsibility of performing the actual drilling duties. They shear the wood fibers as the bit makes its journey through the material, bequeathing a smooth and pristine hole devoid of splintering or tear-out.

Flutes: Typically, Brad Point bits are bedecked with two flutes that trace their path along the bit’s length. As you engage in the act of drilling, these flutes take on the role of ridding the hole of wood chips and debris, ensuring that the drilling process remains smooth, efficient, and immune to overheating.

Shank: The shank, often overlooked but undeniably vital, is the portion of the drill bit that nestles within the drill’s chuck. It plays the role of securing the bit in its rightful place during drilling. Brad Point bits usually feature a cylindrical shank that’s compatible with most standard drill chucks.

Body: The body of the Brad Point drill bit encompasses the spurs, cutting lips, and flutes. It stretches from the tip to the shank and houses the components that carry out the drilling operation and ensure chip removal.

Diameter and Length Variation: Brad Point drill bits present themselves in an array of diameters and lengths, each designed to cater to different woodworking requirements. The choice of bit diameter hinges on the desired hole size, while the bit’s length determines how deep you can delve into your woodworking masterpiece.

Material Construction: Brad Point bits typically emerge from the crucible of high-speed steel (HSS) or other top-tier steel alloys. Some premium variants may even flaunt carbide or other specialized materials to enhance their durability and longevity.

Overall Design: The overarching design of a Brad Point drill bit is calibrated to meet the demands of precision woodworking tasks. It excels in creating holes with precise placement and minimal splintering, making it the preferred choice for doweling, joinery, and various other scenarios where precision reigns supreme.

Limited Versatility: It’s important to underscore that while Brad Point bits reign supreme in the world of wood, they aren’t cut from the same cloth as their brethren designed for metals and masonry. Their unique design may render them unsuitable for those domains, but within wood, they thrive, leaving behind holes that are a testament to precision and aesthetics.

Applications of Brad Point Drill Bits

Brad Point drill bits are the trusted companions of woodworkers and craftsmen when the goal is to drill precise and clean holes in wood and wood-related materials. They excel in applications where spot-on hole placement and minimal splintering are non-negotiable.

Here’s a glimpse into the valuable applications where Brad Point drill bits shine:

Doweling: Brad-point bits are the artisans behind drilling holes in wood to accommodate dowels. The precision they bring to the table ensures that the dowels fit snugly, culminating in joints that are as sturdy as they are dependable, whether in the realm of furniture, cabinets, or other woodworking projects.

Joinery: Brad-point bits are the architects of choice for various joinery techniques, including the venerable mortise and tenon joints. They fashion precise holes for the tenons to find their homes, resulting in connections between wooden pieces that are strong and unyielding.

Cabinetmaking: Cabinetmakers rely on Brad Point drill bits when it’s time to drill holes for concealed hinges, shelf pins, and other hardware components. The clean entry and exit holes bestowed by these bits play a pivotal role in elevating the overall professional appearance of the cabinets.

Furniture Making: When crafting furniture, woodworkers lean on Brad-point bits to create holes for wooden plugs or buttons. These holes artfully conceal screws, becoming a hallmark of furniture assembly with flair.

Decorative Work: Brad Point bits, with their penchant for precision, come into their own when intricate and decorative designs need to be etched into wood. They are the artists behind the holes that house inlays, decorative pegs, or accents in woodworking projects.

Woodturning: Woodturners harness the power of Brad Point bits to create holes for the installation of centers or inlay work in turned wooden treasures like bowls, vases, and spindles.

Flute-making: In the realm of music, musicians and flute makers turn to Brad Point bits to craft precise and clean boreholes inside wooden flutes, recorders, and other musical instruments.

Staircase Construction: When constructing staircases, Brad Point drill bits are the trusted tools for creating precise holes for spindles and balusters. This ensures not just security but also a staircase that stands as a testament to aesthetics.

Shelving Systems: During the creation of custom shelving systems, Brad Point bits are enlisted to drill holes for shelf support pins, ensuring that the shelves stand level and sturdy.

Wooden Toys: Crafters and toy makers turn to Brad Point bits to create holes for axles, wheels, and other components in wooden toys, guaranteeing a construction that’s robust and safe.

Architectural Woodwork: In the world of architectural woodwork, precision and aesthetics share the spotlight. Brad Point drill bits are the artisans responsible for drilling holes for stair railings, newel posts, and intricate wood trim, ensuring that the final product is a masterpiece in both form and function.

Luthiery: In the realm of crafting stringed instruments, known as luthiery, Brad Point bits step up to craft precise holes for tuning pegs, bridge pins, and other components that have a profound impact on the instrument’s tone and playability.

Advantages of Using Brad Point Drill Bits

The deployment of Brad Point drill bits carries with it a slew of advantages, rendering them the preferred choice for woodworking and other applications that demand precision and the creation of pristine holes in wood and wood-related materials.

Here’s a glimpse into the key advantages offered by Brad Point drill bits:

Accurate Hole Placement: Brad-point bits sport a sharp and centered tip adorned with spurs, a combination that meticulously homes in on the center of the hole. This obviates the need for a center punch or additional markings on your workpiece, ensuring that the hole is born in precisely the right place.

Clean Entry and Exit Holes: The spurs that grace Brad Point bits are artisans when it comes to creating an immaculate entry point on the material’s surface. Additionally, the cutting lips skillfully shear the wood fibers, bestowing upon you an exit hole that’s a picture of perfection, with minimal splintering or tear-out on the backside of your workpiece.

Reduced “Walking”: The spurs on Brad Point bits serve as guardians against one of the drill bit’s vices – wandering or “walking” when you commence drilling. This feature is your trusted ally in maintaining hole accuracy and steering clear of unintended hole placement.

Precise Sizing: Brad Point drill bits, available in an array of diameters, give woodworkers the freedom to choose the size that’s the perfect fit for their projects. This precision in sizing is essential, particularly when doweling and other joinery techniques are in play.

Strong Dowel Joints: The holes created by Brad-point bits align seamlessly with the dowels’ diameter. This meticulous precision results in dowel joints that snugly fit together, augmenting the strength and stability of furniture and other wooden assemblies.

Smooth Drilling Action: The cutting lips on Brad Point bits excel at shearing wood fibers cleanly as the bit penetrates, delivering a smooth drilling experience devoid of excessive heat buildup or chatter.

Versatile in Woodworking: Brad Point drill bits are versatile players, well-suited for a wide range of woodworking tasks. Whether it’s joinery, cabinetmaking, furniture assembly, or the creation of decorative elements, they have your back. They are the go-to choose for drilling holes for concealed hinges, wooden plugs, and decorative accents.

Reduced Need for Cleanup: Brad Point bits are often a one-stop solution, eliminating the need for additional finishing or cleanup work, courtesy of the clean entry and exit holes they craft. This not only saves precious time but also preserves your effort in woodworking projects.

Less Tear-Out: The design of Brad Point bits keeps tear-out and splintering at bay, even when you’re drilling through hardwoods and veneered plywood. The result is a set of holes that’s smoother and more professional-looking.

Consistent Performance: Brad Point bits are known for maintaining their sharpness and drilling performance over time. When cared for and sharpened correctly, they offer a level of consistency and reliability that’s hard to match.

Ideal for Delicate Woods: Brad Point bits are a woodworker’s best friend when it comes to drilling into delicate and precious woods. They reduce the risk of damage and waste that can be associated with tear-out or misalignment.

Wide Availability: Brad Point drill bits are readily available at hardware stores, making them accessible to professional woodworkers and hobbyists alike.

In summary, Brad Point drill bits are celebrated for their precision, accuracy, and the ability to create holes in wood that are nothing short of works of art. These advantages catapult them to the forefront of woodworking tasks where whole quality and the fit of dowels or joinery components are non-negotiable.

Tips for Using Brad Point Drill Bits

Harnessing the power of Brad Point drill bits effectively in your woodworking projects demands a keen eye and attention to a slew of essential tips.

Here’s a guide to ensuring that your Brad Point bits deliver top-notch results:

- Secure Workpiece: Ensure that your workpiece is securely held in place, either with clamps or a vice. This prevents any unintended movement during drilling, preserving the accuracy of your holes.

- Correct Bit Diameter: Select the correct bit diameter for your project. It’s essential to choose a size that matches your desired hole size accurately.

- Mark Hole Location: Mark the hole location accurately on your workpiece, using a square or other measuring tools as needed.

- Drill Press: If possible, utilize a drill press for superior control and accuracy, especially in precision work.

- Drilling Speed: Adjust the drill’s speed according to the type of wood you’re drilling. Generally, slower speeds are suitable for hardwoods, while faster speeds work well for softwoods.

- Start Slowly: Initiate drilling slowly to create a centered indentation. Gradually increase the speed as the bit engages with the wood.

- Depth Marking: Use masking tape or a depth stop to mark the desired drilling depth, preventing over-drilling.

- Chip Clearance: Periodically clear wood chips and debris from the hole to maintain optimal drilling performance. This prevents overheating and ensures a clean drilling process.

- Avoid Leaning: Avoid leaning the drill to the side during drilling, as this can result in off-center holes.

- Even Pressure: Apply steady and even pressure to the drill bit without forcing it. This prevents binding and overheating.

- Inspect the Bit: Regularly inspect the drill bit for wear, dullness, or damage. Promptly replace worn or damaged bits for optimal performance.

- Lubrication: In cases of resistance, especially with hardwoods, consider using a woodworking lubricant or a wax stick to reduce friction and heat.

- Clear Chips: For deep holes, withdraw the bit partially occasionally to allow wood chips to clear. This maintains drilling efficiency and prevents overheating.

- Backing Board: Place a backing board or sacrificial wood beneath the workpiece when concerned about tear-out on the exit side.

Brad Point Drill Bit Variations

Brad Point drill bits don’t just come in one standard flavor; they offer a spectrum of variations, each meticulously designed to cater to specific woodworking needs and preferences. These variations come adorned with different features and advantages, enabling woodworkers to select the perfect match for their projects.

Here’s a look at some common variations of Brad Point drill bits:

Standard Brad Point Bits: These are the most common and widely used Brad Point drill bits. They feature a sharp point with spurs for precise hole placement and cutting lips for clean drilling. Standard Brad Point bits come in various diameters and are suitable for a wide range of woodworking tasks.

Long Brad Point Bits: Long Brad Point bits boast an extended length, allowing woodworkers to drill deeper holes. They are ideal for applications where longer-than-standard bits are required, such as creating deep mortises or drilling holes in thick workpieces.

Auger-Style Brad Point Bits: Auger-style Brad Point bits take a page from traditional auger bits with their spiral design. They offer efficient chip removal and excel at deep-hole drilling. These bits are excellent choices for drilling holes for wooden pegs and deep dowel joinery.

Tapered Brad-Point Bits: Tapered Brad Point bits feature a gradual taper, allowing woodworkers to create holes with varying diameters within the same hole. They prove valuable in scenarios like creating countersunk holes for screws with varying head sizes or for decorative purposes.

Multi-Spur Brad Point Bits: Multi-spur Brad Point bits take the spurs to the next level by adding extra spurs or cutting edges on the sides of the bit. This design enhances cutting efficiency and reduces splintering, making them ideal for hardwoods and other dense woods.

Brad Point Forstner Bits: Combining the features of Brad Point and Forstner bits, these drill bits are specifically designed for drilling flat-bottomed holes with precise edges. They excel at creating clean, flat-bottomed holes for applications like hinge installation or doweling.

Adjustable Brad Point Bits: Adjustable Brad Point bits allow woodworkers to customize the hole diameter within a specified range. This versatility is handy when you need to drill holes of varying sizes without changing bits frequently.

Self-Centering Brad Point Bits: Self-centering Brad Point bits are designed with a spring-loaded guide that automatically centers the bit on the workpiece. This feature is particularly useful for drilling holes for hinges and other hardware with exact alignment requirements.

Carbide-Tipped Brad Point Bits: Carbide-tipped Brad Point bits enhance durability and longevity. The carbide tips are exceptionally hard and resistant to wear, making these bits suitable for heavy-duty and long-lasting use.

Left-Handed Brad Point Bits: Left-handed Brad Point bits rotate counterclockwise, making them suitable for use in reverse. They are helpful when you need to remove screws or bolts with damaged heads or threads.

Brad Point Plug Cutters: These specialized bits are designed to create wooden plugs of specific diameters. They work by drilling a hole and simultaneously cutting a wooden plug from the same material. This is a handy technique for concealing screw heads or filling holes in woodworking projects.

Conclusion

In the world of woodworking, precision is paramount, and the tools you choose can make all the difference in the quality of your finished projects. Brad Point drill bits stand as a testament to precision and finesse in hole drilling.

With their pinpointed tips, cutting spurs, and clean-cutting lips, they excel at creating accurate and clean holes in wood, leaving little room for splintering, tear-out, or misalignment.

Whether you’re crafting furniture, cabinets, musical instruments, or engaged in any woodworking endeavor that demands impeccable hole quality, Brad Point drill bits are your trusted companions.

Their ability to locate the center of the hole precisely, coupled with their efficient chip removal, makes them the preferred choice for tasks ranging from doweling and joinery to decorative work and beyond.