For those venturing into woodworking or carpentry, the term “panel saw” might sound like a mysterious incantation from a secret craft.

But fear not, for we’re here to unravel the enigma and shed light on what is a panel saw. In the world of precision cutting and crafting, the panel saw stands as a true cornerstone, enabling artisans to transform raw materials into works of art.

In the pages that follow, we’ll delve into the inner workings of this versatile tool, exploring its anatomy, functions, and the magic it brings to the workshop.

Whether you’re a seasoned pro or a curious novice, join us on this journey to demystify the panel saw and discover the remarkable possibilities it holds. So, grab your safety goggles, roll up your sleeves, and embark on this woodworking adventure together.

Historical Evolution: Origins of Panel Saws

In this comprehensive exploration, we delve into the fascinating historical evolution and origins of panel saws. Panel saws have played a pivotal role in woodworking for centuries, and their development is a testament to human ingenuity and craftsmanship. Join us as we uncover the key milestones that have shaped these indispensable tools.

Early Origins of Woodworking Tools

The roots of panel saws can be traced back to ancient civilizations, where the art of woodworking began to take shape. In ancient Egypt, for instance, woodworking tools were essential for crafting intricate furniture, intricate carvings, and architectural marvels like the pyramids. While these early tools may not resemble the panel saws we know today, they laid the foundation for the evolution of woodworking instruments.

Emergence of the Hand Saw

The evolution of panel saws gained momentum during the Middle Ages when the hand saw debuted. These early hand saws were primarily used for cutting logs into lumber. Artisans honed their skills, perfecting the art of precision cutting, which was crucial for constructing structures, ships, and other wooden creations of the era.

The Renaissance Era: Advancements in Woodworking

As the Renaissance period dawned, woodworking experienced a renaissance of its own. Panel saws began to take on a more recognizable form, with wooden handles and thin, sharp blades. Artisans during this era started creating intricate designs and patterns in wood, paving the way for the decorative woodworking we admire today.

Industrial Revolution: Transformation of Panel Saws

Blades became sharper and more durable, and handles evolved into ergonomic designs for increased efficiency and comfort.

20th Century Innovations

In the 20th century, I witnessed remarkable innovations in panel saws. Advancements in metallurgy led to the development of high-quality steel blades, enhancing the precision and durability of these tools. Electric and automated panel saws also emerged, revolutionizing woodworking industries and streamlining production processes.

Modern Panel Saws: Precision and Versatility

In the contemporary era, panel saws have reached new heights of precision and versatility. Manufacturers employ cutting-edge technology to produce saws that cater to a wide range of woodworking needs. From handheld panel saws for intricate detailing to large, automated saws for mass production, there’s a panel saw for every application.

The Future of Panel Saws

Looking ahead, the future of panel saws appears promising. We can expect even greater precision, efficiency, and safety in panel saws, making woodworking more accessible and enjoyable for professionals and hobbyists.

Panel saws are essential tools used in woodworking and other industries to cut large sheets of material, such as plywood, MDF (Medium-Density Fiberboard), and particleboard. There are several types of panel saws designed for different purposes and applications. Here are some common types of panel saws:

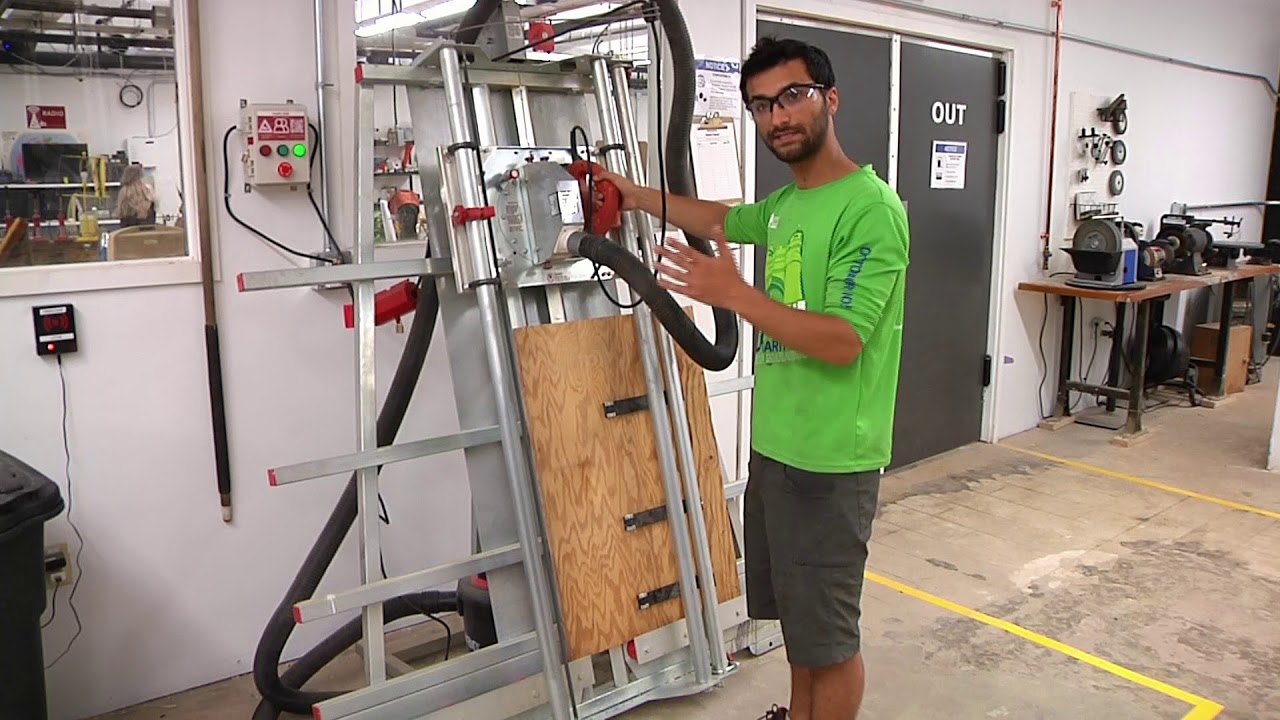

Vertical Panel Saw:

- A vertical panel saw is designed to make vertical cuts in large panels. It has a vertically oriented saw blade that moves up and down.

- These saws are ideal for cutting large panels into smaller, more manageable pieces and making precise vertical cuts.

- They are commonly used in woodworking shops, sign-making, and other industries that require vertical cutting.

Horizontal Panel Saw:

- Horizontal panel saws are designed to make horizontal cuts in large panels. They have a horizontally oriented saw blade that moves across the panel.

- These saws are often used for cutting panels to size, such as for cabinet doors or countertops.

- Horizontal panel saws are suitable for high-volume production environments.

Sliding Table Saw:

- Sliding table saws are versatile machines with a sliding tables allowing precise crosscuts and rip cuts.

- They can handle large panels and smaller workpieces, making them popular in woodworking shops.

- Sliding table saws come in various configurations, including single-blade and double-blade models.

Beam Saw:

- Beam saws are large, automated panel saws used for high-volume production.

- They have a bridge-like structure with multiple saw blades that can cut several panels simultaneously.

- Beam saws are commonly used in industries like furniture manufacturing and cabinet making.

CNC Panel Saw:

- CNC (Computer Numerical Control) panel saws are highly automated machines programmed to make precise cuts with minimal manual intervention.

- They are ideal for complex cuts, patterns, and custom woodworking projects.

- CNC panel saws are widely used in advanced woodworking and manufacturing facilities.

Track Saw:

- It features a saw blade attached to a track or guide rail, allowing for straight and accurate cuts.

- Track saws are popular among carpenters and contractors for on-site cutting tasks.

Table Saw with Panel Cutting Attachments:

- Some table saws can be equipped with panel-cutting attachments or extensions to handle larger panels.

- These attachments provide support and stability for cutting large sheets of material on a table saw.

Manual Panel Saw:

- Manual panel saws are basic, hand-operated saws designed for small-scale panel cutting.

- They are often used in DIY projects and small woodworking shops.

Anatomy of a Panel Saw: A Comprehensive Guide

Whether you’re a seasoned woodworker or just starting your woodworking journey, understanding the intricacies of a panel saw can significantly enhance your woodworking experience.

Introduction to Panel Saws

Panel saws are a fundamental tool in the woodworking industry, designed to make precise cuts in large sheets of wood, plywood, or other materials.

They come in various sizes and configurations, each tailored to specific woodworking needs. In this article, we’ll explore the key components that make up a panel saw and provide valuable insights into how these components work together seamlessly.

The Main Frame

At the core of every panel saw lies the main frame, which serves as the structural foundation of the entire machine. The main frame is typically constructed from heavy-duty steel or cast iron to stabilize and minimize vibrations during operation. This stability is essential for accurate cuts, especially with large panels.

Sliding Carriage

One of the standout features of a panel saw is its sliding carriage. This component allows the user to move the cutting tool (usually a circular saw blade) horizontally along the length of the panel. The sliding carriage has precision guides and bearings to ensure smooth and controlled movement, resulting in clean and straight cuts.

Saw Blade

The heart of any panel saw is undoubtedly its saw blade. These blades come in various sizes and tooth configurations, depending on the type of cuts you wish to make. A sharp and well-maintained blade is crucial for achieving precise cuts with minimal tear-out. Regular maintenance, such as sharpening and cleaning, is essential to keep the blade in optimal condition.

Dust Collection System

Woodworking generates a significant amount of dust and debris, which can harm both the operator and the machine itself. Panel saws often have dust collection systems that remove sawdust from the cutting area.

Cutting Fence

The cutting fence is a vital component that helps guide the panel during the cutting process. It ensures that the material stays aligned and allows for precise rip cuts. Some advanced panel saws even feature electronic positioning systems for the cutting fence, enabling automated and highly accurate adjustments.

Safety Features

Safety should always be a top priority in any woodworking environment. Panel saws have various safety features, including blade guards, emergency stop buttons, and overload protection mechanisms. These features are designed to minimize the risk of accidents and ensure the operator can confidently work.

Types of Panel Saws

Panel saws come in several configurations, each tailored to specific woodworking needs. Understanding the various types can help you choose the best workshop.

Vertical Panel Saws

Vertical panel saws are designed to make vertical cuts on large sheets of material. They are ideal for cutting plywood, melamine, and other panel materials. These saws save space and are highly efficient for high-volume cutting tasks.

Horizontal Panel Saws

Horizontal panel saws are better suited for cutting larger panels and heavy materials. They are often used in industrial settings where precision and speed are paramount. Horizontal panel saws can handle sheets of various sizes and thicknesses with ease.

Sliding Table Panel Saws

Sliding table panel saws combine the advantages of both vertical and horizontal saws. They feature a sliding table that allows for precise crosscuts and rip cuts. These versatile machines are favored by many woodworkers for their flexibility and Accuracy.

Maintenance and Care

To ensure that your panel saw continues to perform at its best, regular maintenance is essential. Here are some tips to keep your panel saw in optimal condition:

- Blade Maintenance: Regularly inspect and sharpen the saw blade to ensure clean and precise cuts.

- Clean the Dust Collection System: Keep the dust collection system clean and debris-free to maintain efficient dust removal.

- Lubrication: Lubricate moving parts, such as bearings and guides, to prevent excessive wear and ensure smooth operation.

- Safety Checks: Regularly inspect safety features to ensure they are functioning correctly.

Panel saws are woodworking tools designed to make precise cuts in large sheets of wood or other materials. They work on using a circular saw blade or a vertical cutting blade to slice through the material. These saws are commonly used in carpentry, cabinetry, and furniture making.

Crosscutting vs. Ripping:

- Crosscutting: Crosscutting is cutting a material across its width, perpendicular to its length. Panel saws can make clean and accurate crosscuts, essential for creating precise, square, and dimensionally accurate pieces for woodworking projects.

- Ripping: Ripping involves cutting a material along its length, parallel to the grain. Panel saws can also be used for ripping. Still, the blade and setup may need to be adjusted to ensure straight and uniform cuts when working with longer pieces of material.

Understanding the Difference:

The primary difference between crosscutting and ripping lies in the orientation of the cut relative to the material’s grain. Crosscuts are typically used for cutting boards to length or making shorter, square cuts. Ripping, however, is used for creating strips or planks of consistent width from a larger piece of material.

Cutting Techniques:

- Crosscutting Technique: When crosscutting with a panel saw, it’s essential to measure and mark the desired length accurately. Use a square to ensure a perpendicular cut. Position the material on the saw’s table, align the cut line with the blade, and push the material through the saw using a smooth, steady motion.

- Ripping Technique: To rip with a panel saw, set the saw’s fence at the desired width, aligning it with the cut line. Feed the material through the saw while pressing it against the fence to maintain a consistent width throughout the cut.

Tips for Precise Cuts:

- Use a Sharp Blade: A sharp blade reduces tear-out and ensures cleaner cuts.

- Measure and Mark Carefully: Accurate measurements and markings are crucial for precision.

- Use a Straight Edge or Fence: A straight edge or fence helps guide the material for straight cuts.

- Maintain a Steady Feed Rate: Consistent pressure and speed while feeding the material through the saw result in cleaner cuts.

Common Applications:

Panel saws are commonly used for various woodworking tasks, including:

- Cabinet Making: Cutting plywood sheets for cabinet components.

- Furniture Making: Creating parts like tabletops, panels, and legs.

- Trim and Molding: Cutting trim pieces and moldings.

- Architectural Millwork: Producing custom millwork components.

- Sign Making: Cutting materials for signage and displays.

Where Panel Saws Shine:

Panel saws are handy in workshops and industries where precision and efficiency are essential. They shine in scenarios where large sheets of material, such as plywood or MDF, must be accurately cut into smaller pieces or where repetitive crosscutting and ripping tasks are expected. Their ability to make clean, square cuts makes them indispensable tools in many woodworking and construction applications.

Choosing the Right Panel Saw: Factors to Consider

When it comes to woodworking, one of the most essential tools in your arsenal is a panel saw.

Budget, Workspace, and Project Needs

1. Budget Matters

Your budget is often the first and most significant factor when purchasing a panel saw. These tools come in a wide range of prices, and while it may be tempting to go for the most expensive option, it’s essential to balance your budget with your woodworking requirements.

For beginners, a more affordable entry-level panel saw can be an excellent starting point. These models offer a good balance between cost and functionality. However, for professionals with specific needs and heavy usage, investing in a higher-end panel saw with advanced features may be justified.

2. Workspace Constraints

The available space in your workshop is another critical factor. Panel saws come in various sizes, and it’s crucial to ensure that your chosen saw fits comfortably within your workspace. Measure your available space carefully, accounting for the saw’s footprint and the clearance required for safe operation.

If your workshop has limited space, consider a compact panel saw that can be easily maneuvered and stored when not in use. On the other hand, if space is abundant, you may opt for a larger, more versatile model.

3. Project Specifics

The type of projects you undertake plays a significant role in determining the right panel saw for your needs. Consider the following project-related factors:

a. Material Thickness

Different panel saws are designed to handle varying thicknesses of materials. If you frequently work with thick hardwoods, you’ll need a panel saw with a robust motor that can cut through thick stock effortlessly. Conversely, if you primarily deal with thinner materials, a lighter-duty saw may suffice.

b. Cutting Accuracy

For precision cuts and intricate designs, a panel saw with advanced features like laser guides and digital displays can be invaluable. These features help ensure that your cuts are accurate and minimize the margin for error.

c. Portability

If your projects require on-site work or frequent transportation, a portable panel saw with wheels can save you time and effort. These models are designed for easy mobility, allowing you to take your woodworking skills wherever needed.

Conclusion

a panel saw is a versatile and essential tool in woodworking and carpentry. It is designed to make precise and efficient cuts in large sheets of material, such as plywood and MDF. Panel saws come in various types, including vertical and horizontal models. Its ability to make straight, clean cuts with minimal effort makes it a valuable asset in any workshop.

So, whether you’re crafting furniture, cabinets, or any other woodworking project that requires precise cutting of large panels, a panel saw is a tool that can help you achieve professional results.