When working with miter saws, one common question that often arises is, Are miter saw blades reverse threaded? Understanding the threading direction of your miter saw blade is essential for safe and efficient operation.

In this discussion, we will delve into the world of miter saws and explore whether their blades follow a reverse-threaded pattern. So, let’s unravel this mystery and shed light on an essential aspect of woodworking and DIY projects.

Understanding Miter Saw Blades

Understanding miter saw blades is essential for achieving accurate and clean cuts in woodworking and construction projects. Miter saw blades are circular cutting tools specifically designed for use with miter saws, which are power tools used to make angled and precise crosscuts in various materials. Here are vital aspects to understand about miter saw blades:

Blade Diameter: Miter saw blades come in different diameters, typically 7 to 12 inches. The blade diameter affects the maximum depth of cut the saw can achieve. Larger blades can cut through thicker materials.

Arbor Size: The arbor size refers to the diameter of the hole in the blade’s center that fits onto the arbor (spindle) of the miter saw. Standard arbor sizes for miter saws are 5/8 inches and 1 inch. It’s essential to match the arbor size of the blade with that of your miter saw.

Tooth Configuration: Miter saw blades have different tooth configurations to suit various cutting tasks:

- Alternate Top Bevel (ATB): Ideal for general crosscutting and produces clean cuts.

- Triple-Chip Grind (TCG): Designed for rigid materials like hardwoods and metals.

- Flat-Top Grind (FTG): Primarily for ripping along the wood grain.

- High Alternate Top Bevel (Hi-ATB): Provides immaculate and polished cuts for fine woodworking.

Tooth Count: The quantity of teeth on the sharp edge impacts the quality and speed of cuts. Blades with more teeth (80 or more) produce finer cuts, while those with fewer teeth (24 to 40) cut faster but may leave a rougher surface.

Hook Angle: The teeth’ hook angle determines the cut’s aggressiveness. Positive hook angles (e.g., 5 to 15 degrees) are suitable for fast cuts, while negative hook angles (e.g., -5 to -10 degrees) provide smoother, controlled cuts.

Blade Material: Miter saw blades are typically made from high-speed steel (HSS), carbide-tipped, or solid carbide. Carbide-tipped blades are known for their durability and are great for cutting hard or grating materials.

Blade Coatings: Some blades have specialized coatings, such as Teflon, to reduce friction, heat buildup, and resin buildup. Coated blades stay cleaner and last longer.

Specialty Blades: There are specialty miter saw blades designed for specific applications, such as cutting laminate, plastics, or non-ferrous metals. These blades have unique tooth patterns and are optimized for particular materials.

Threaded vs. Reverse Threaded Blades

Threaded and reverse threaded blades refer to the direction in which the blade’s arbor nut is tightened or loosened when mounting or changing the blade on a miter saw. Understanding the difference between threaded and reverse-threaded blades is essential to ensure safe and proper blade installation. Here’s what you need to know:

Threaded Blades

Tightening Direction: With threaded blades, the arbor nut is tightened in the clockwise direction (righty tighty).

Loosening Direction: To loosen the arbor nut, turn it counterclockwise (lefty loosey), the standard direction for most threaded fasteners.

Commonality: Threaded blades with a clockwise tightening direction are the standard and most commonly found on miter saws and other power tools.

Reverse Threaded Blades

Tightening Direction: Reverse threaded blades have a counterclockwise tightening direction, meaning you tighten the arbor nut by turning it counterclockwise (lefty-righty).

Loosening Direction: To loosen the arbor nut on a reverse threaded blade, turn it clockwise (righty loosey).

Less Common: Reverse-threaded blades are less common and may be found on some specific models or brands of miter saws. They are different for most miter saws.

Important Considerations

When changing or installing a miter saw blade, refer to your miter saw’s user manual or manufacturer’s instructions. The manual will specify whether your saw uses a threaded or reverse-threaded arbor nut.

Using the incorrect direction for tightening or loosening the arbor nut can lead to problems, such as difficulty removing the blade or damaging the saw’s spindle. Therefore, it’s crucial to follow the correct direction specified by the manufacturer.

Some miter saws have a spindle lock feature, immobilizing the blade while you tighten or loosen the arbor nut. This feature enhances safety and ease of blade replacement. If your miter saw has this feature, use it when changing the blade.

Threaded and reverse-threaded blades differ in how the arbor nut is tightened or loosened. The manufacturer determines the direction, and following the specified direction is crucial to ensure safe and proper blade installation on your miter saw. Always consult your miter saw’s user manual or manufacturer guidelines for the correct procedure.

Applications of Reverse Threaded Miter Saw Blades

Reverse threaded miter saw blades, also known as reverse tooth miter saw blades or negative rake miter saw blades, have teeth that point in the opposite direction compared to traditional miter saw blades. While they are less commonly used than standard miter saw blades, they do have specific applications where they can be advantageous:

Clean Crosscuts: Reverse threaded miter saw blades are excellent for making clean crosscuts on various materials, including wood, plywood, and laminates. The reverse tooth design helps prevent tear-out and splintering on the top surface of the workpiece.

Delicate Materials: When working with delicate or brittle materials, such as veneer, melamine, or thin plastic laminates, reverse-threaded blades can minimize chipping and cracking by cutting from the bottom side up.

Reducing Tear-Out: For materials like particleboard, oriented strand board (OSB), or plywood, where tear-out can be a significant issue, a reverse threaded blade can result in smoother cuts with less splintering.

Melamine and Laminate Flooring: Reverse threaded blades are often used for cutting melamine-coated particleboard and laminate flooring. They can help achieve precise, chip-free cuts on the top surface.

Mitering and Beveling: These blades can be beneficial when making miter and bevel cuts in hardwoods or engineered wood products, especially if you want to avoid any tear-out or splintering on the finished edges.

Reduced Kickback: Reverse threaded blades can reduce the risk of kickback, as they tend to pull the workpiece downward and against the fence, enhancing stability during cutting.

Plastics and Composites: When working with plastics, composites, or materials prone to melting or fusing from the heat generated by the blade, a reverse-threaded blade can help minimize these issues by cutting from the bottom side.

Improved Safety: The design of reverse threaded blades can upgrade security by lessening the probability of the blade grabbing or pulling the workpiece away from the operator, particularly when cutting thin or brittle materials.

Common Myths and Misconceptions about a miter saw blade threading

There are several common myths and misconceptions about miter saw blade threading that can lead to confusion or misinformation. Addressing these misconceptions is essential to ensure that individuals make informed decisions when choosing and using miter saw blades. Here are some of the most prevalent myths and misconceptions:

Myth: Reverse Threaded Blades Are Always Better

Fact: Reverse-threaded miter saw blades have their advantages in specific applications, as mentioned earlier. However, they are only sometimes superior to standard threaded blades. The two choices depend on the material and the desired cut quality.

Myth: Reverse Threaded Blades Are for Left-Handed Users

Fact: The orientation of the blade’s teeth has nothing to do with whether the user is left-handed or right-handed. Reverse-threaded blades are used based on the material and the desired cutting results, not the operator’s handedness.

Myth: Reverse Threaded Blades Are More Dangerous

Fact: Both reverse-threaded and standard-threaded blades can be used safely when proper safety precautions are followed. The design of reverse threaded blades can reduce the risk of kickback in some situations, but all miter saw blades can be dangerous if not used correctly.

Myth: Reverse Threaded Blades Are Only for Specialized Applications

Fact: While reverse-threaded blades excel in specific applications, they are not exclusively for specialized tasks. They can be used for woodworking and cutting tasks where a clean top surface or reduced tear-out is desired.

Myth: Reverse Threaded Blades Are Harder to Find

Fact: Reverse-threaded miter saw blades may not be as commonly available as standard threaded blades, but they are still accessible through many hardware stores and online retailers. They are common.

Myth: Reverse Threaded Blades Are More Expensive

Fact: The price of a miter saw blade relies upon different variables, including size, quality, and brand, but whether it’s reverse threaded or standard threaded does not necessarily dictate the cost. There can be reverse threaded blades that are cheaper and more expensive than standard threaded ones.

Myth: Reverse Threaded Blades Always Prevent Tear-Out

Fact: While reverse threaded blades can help reduce tear-out on the top surface of the material, they do not eliminate it, especially when dealing with delicate or brittle materials. Achieving tear-out-free cuts may still require additional techniques or tools.

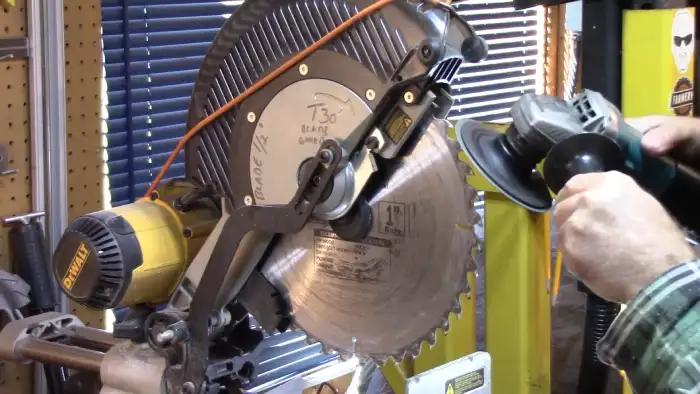

How to Identify Reverse Threaded Blades?

Identifying reverse-threaded miter saw blades is crucial in selecting the right tool for specific cutting tasks. The easiest way to confirm a reverse threaded blade is by checking the packaging, as manufacturers often label the blade type clearly.

Additionally, examining the blade’s teeth can be helpful; reverse threaded blades have teeth that point downward when mounted on the saw, which aids in preventing tear-out on the material’s top surface. Some blades may also have markings etched onto them, indicating “reverse” or “negative rake.”

User Manual

Consult the user manual for your miter saw or the blade, as it may provide information about compatible blade types. If in doubt, seeking advice from knowledgeable sources, such as store employees or experienced woodworkers, can help ensure you choose the right blade for your project. Remember that reverse threaded blades are just one option, and their suitability depends on factors like the desired cut quality and the material being worked on.

Maintenance and Care of miter saw blades

Proper maintenance and Care of your miter saw blades are vital to ensure their longevity, performance, and, most importantly, safety. It begins with routine cleaning to remove the buildup of sawdust, resin, and debris. Inspecting the blade for visible damage before and after each use is essential to detect any issues, such as missing or chipped teeth, warping, or cracks, that may compromise the blade’s functionality.

Lubrication

Lubrication can help reduce friction and heat, especially if your blade has lubrication slots or channels. Sharpening the blade using the appropriate tools or services can restore its cutting efficiency if needed.

Storing the blades in a dry, relaxed environment, proper balancing, and ensuring you’re using the correct blade for the material and task contribute to blade longevity and performance.

Remember to follow the manufacturer’s guidelines and prioritize safety when maintaining and caring for your miter saw blades, including wearing the necessary protective gear and observing proper cooling and downtime practices to prevent overheating.

Safety Considerations for Miter Saw Blades

Safety is paramount when working with miter saw blades, as these tools can be powerful and potentially dangerous. Here are essential safety considerations to keep in mind when using miter saw blades:

Read the Manual: Always start by reading the user manual provided by the manufacturer. It contains crucial information on safe operation, maintenance, and specific recommendations for your miter saw model.

Wear Appropriate Safety Gear: Before operating the saw, wear the necessary safety equipment, including safety glasses or a face shield to protect your eyes from debris, hearing protection to guard against noise, and dust masks or respirators to avoid inhaling sawdust.

Check the Blade: Before each use, inspect the miter saw blade for any visible damage, including missing or chipped teeth, warping, or cracks. Damaged blades should be replaced immediately.

Secure the Workpiece: Always secure the workpiece firmly to the miter saw’s fence and table using clamps or other appropriate methods. This prevents the workpiece from moving during the cut and reduces the risk of kickback.

Use a Blade Guard: Ensure that the saw’s blade guard is in good working condition and functional. Never disable or remove the blade guard while the saw is in operation.

Mind the Cut Line: Always align the blade with the cut line on your workpiece and make sure the blade is at full speed before entering the material. Do not start the cut with the blade in contact with the workpiece.

Use Appropriate Blades: Select the correct blade type for the material you’re cutting and the cut you’re making. Using the correct blade can lead to efficient cutting and increased safety risks.

Keep Hands Away: Always protect your hands and fingers from the blade. Never attempt to remove cut-offs or debris from the table or blade while the saw is running.

Conclusion

Miter saw blades are not inherently reverse threaded; their threading can vary depending on the specific blade design and intended application.

Reverse threaded miter saw blades, also known as negative rake or reverse tooth blades, have teeth that point in the opposite direction compared to standard blades.

These reverse-threaded blades are designed to reduce tear-out and splintering on the top surface of the cut material, making them suitable for particular woodworking tasks.