When it comes to the world of woodworking, two essential tools stand out – the dovetail saw and the tenon saw. These names may sound like jargon to the uninitiated. Still, for seasoned artisans and DIY enthusiasts they represent precision and craftsmanship in its purest form.

In this article, we delve into the intricate details of the dovetail saw vs. tenon saw, comparing their features, functions, and applications. So, if you want to enhance your woodworking skills or are curious about these specialized saws, stay with us as we unravel the differences between the dovetail and tenon saw.

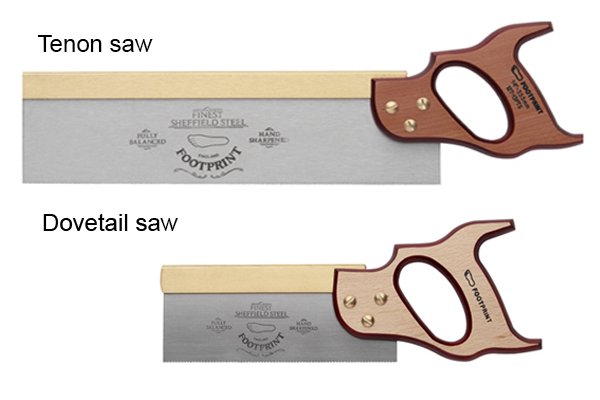

Tenon Saw

When it comes to woodworking, having the right tools can make all the difference in the world. Among the essential tools in a woodworker’s toolkit is the tenon saw, a true workhorse renowned for its power and precision.

The tenon saw is designed for cutting tenon joints, hence its name. Tenon joints are a fundamental component in traditional woodworking, known for their strength and durability. This saw is crafted to handle these joints with efficiency and accuracy.

Key Features of the Tenon Saw

One of the standout features of the tenon saw is its heavy-duty teeth. Unlike finer-toothed saws like the dovetail saw, the tenon saw boasts coarser teeth, typically 10 to 12 per inch (TPI). This tooth configuration allows for efficient cutting of larger pieces of wood, making it ideal for tenon joints.

Another critical aspect of the tenon saw is its wide blade. The tenon saw features a broad blade that provides stability during cutting. This stability is essential when working with thicker stock, ensuring straight and precise cuts. It’s a tool designed for robust, sturdy joinery.

The Back Saw Design

The tenon saw belongs to a category of saws known as back saws. These saws are characterized by a stiffening rib or “back” along the blade’s top edge. This design minimizes flex, resulting in accurate cuts, especially when precision is paramount.

The Dovetail Saw

In the world of woodworking, the dovetail saw stands out as a testament to precision and fine craftsmanship. With its distinctive fine teeth and narrow blade, this tool is a staple for woodworkers who demand accuracy and clean cuts in their projects.

In this article, we’ll delve into the intricacies of the dovetail saw and discover why it’s a must-have for woodworking enthusiasts.

The Anatomy of a Dovetail Saw

One of the standout features of the dovetail saw is its fine teeth. Unlike saws with coarser teeth, the dovetail saw boasts a high tooth count, typically ranging from 14 to 17 teeth per inch (TPI). This high TPI count allows for incredibly accurate and clean cuts, making it ideal for intricate joinery work, especially dovetail joints.

The narrow blade of the dovetail saw is another critical element. This design feature provides excellent control over the cut, enabling woodworkers to create precise, delicate joints easily. It’s the perfect tool for crafting drawers, boxes, and other exemplary woodworking projects where precision is paramount.

Versatility in Joinery

While the dovetail saw is renowned for its prowess in crafting dovetail joints, its applications extend beyond this speciality. Woodworkers often use it for other joinery tasks, including half-blind dovetails, through dovetails, and even cutting small tenons when needed. This versatility makes the dovetail saw a valuable addition to any woodworking toolkit.

The Choice for Precision

When choosing a saw for precision work, the dovetail saw is the undisputed champion. Its fine teeth and narrow blade allow woodworkers to achieve intricate cuts that fit together perfectly, leaving no gaps in the joints.

Standard Features Between Dovetail Saw and Tenon Saw

In the world of woodworking, two saws often find themselves in the hands of craftsmen and enthusiasts: the dovetail saw, and the tenon saw. While these saws serve distinct purposes, they also share several standard features that make them invaluable tools for any woodworker. In this article, we’ll explore these standard features, highlighting how they contribute to the versatility and utility of both saws.

1. Backsaw Design

The dovetail and tenon saw belong to a category of saws known as backsaws. This designation refers to the stiffening rib or “back” along the top edge of the saw blade. The backsaw design serves a crucial purpose – minimizing blade flex during cutting, ensuring the saw blade remains rigid and straight. This feature is particularly essential when paramount precision results in clean, accurate cuts.

The backsaw design is evident in both saws’ thin, narrow blades. This design enhances stability and allows fine control over the saw’s path, which is especially important when crafting intricate joinery.

2. Fine Toothed Blades

Another shared characteristic between the dovetail and tenon saw is their fine-toothed blades. While the tooth count may vary slightly between the two saws, they both feature relatively high tooth counts compared to other saws. The dovetail saw typically has 14 to 17 teeth per inch (TPI), while the tenon saw usually ranges from 10 to 12 TPI.

These fine teeth contribute to the precision of both saws. They result in cleaner, smoother cuts that require less sanding and finishing work. Whether crafting a delicate dovetail joint with the dovetail saw or making a precise tenon cut with the tenon saw, the fine teeth on both blades ensure the final result is nothing short of perfect.

3. Blade Length

While there can be some variation in blade length among different models and brands, both the dovetail saw, and the tenon saw typically feature relatively short blades compared to other saw types. This shorter blade length is intentional and aids in achieving greater control over the saw during use.

The shorter blade allows precise, controlled cuts when working in confined spaces or crafting intricate joinery. It also reduces the chances of the blade wandering off course, which is particularly advantageous when cutting joints that demand tight tolerances.

4. Precision Joinery Focus

Both saws are primarily designed for precision joinery work. While their applications may differ slightly, they excel in creating solid and well-fitting joints. With its narrow blade and fine teeth, the dovetail saw is ideal for crafting dovetail joints and other delicate joinery like half-blind dovetails and through dovetails. On the other hand, with its wider blade and still fine teeth, the tenon saw shines in the creation of tenon joints and mitre joints.

5. Versatility

Although the dovetail and tenon saw have their specialities, they are not limited to just one type of joint. Woodworkers often find creative ways to use these saws in various applications. For example, the dovetail saw can create small tenons when needed. In contrast, the tenon saw can be used for mitre joints in addition to its primary role in tenon joinery.

6. High-Quality Construction

The manufacturers of these saws understand the demands of precipitate from high-quality steel, ensuring durability and sharpness. Some saws even feature reinforced backs to enhance blade stability further.

Task Comparison Between Dovetail Saw and Tenon Saw

Selecting the right tool in woodworking is crucial to achieving precision and efficiency. Two indispensable saws often come into play are the dovetail and tenon saw. While these tools share some standard features, they specialize in different tasks. In this article, we will go through a task comparison between the dovetail saw and the tenon saw, highlighting their unique roles in woodworking.

Dovetail Saw: The Precision Specialist

The dovetail saw is synonymous with precision joinery work. Its unique features suit tasks that demand the utmost accuracy and finesse. Let’s explore the specific tasks where the dovetail saw shines:

Creating Dovetail Joints: As its name suggests, the dovetail saw is the go-to tool for crafting dovetail joints. These joints are renowned for their strength and aesthetic appeal. Dovetail joints are commonly found in drawers, cabinets, and high-end furniture. The dovetail saw’s fine teeth and narrow blade are perfectly tailored for achieving the tight-fitting, interlocking cuts that define dovetail joints.

Crafting Delicate Joinery: Beyond dovetail joints, the dovetail saw is adept at creating other intricate joinery, such as through and half-blind dovetails. Its fine teeth allow woodworkers to make precise, delicate cuts that result in visually pleasing and structurally sound joints.

Cutting Small Tenons: While not its primary function, the dovetail saw can cut small tenons when needed. This versatility makes it a valuable addition to the woodworking toolkit.

Tenon Saw: The Powerhouse for Larger Joints

In contrast, a tenon saw is a robust tool for efficiently cutting larger joints. Its characteristics make it indispensable for tasks requiring power and precision in equal measure. Let’s explore the tasks where the tenon saw excels:

Crafting Tenon Joints: The tenon saw is named for its prowess in cutting tenon joints, essential components in furniture and woodworking. Tenon joints are known for their strength, making them an ideal choice when constructing tables, chairs, and other pieces of furniture where structural integrity is paramount.

Creating Miter Joints: Tenon saws are also well-suited for crafting mitre joints, commonly used in frames, mouldings, and decorative woodworking projects. The saw’s wide blade and cutting power ensure clean, precise cuts for these angular joints.

Efficient Cuts in Large Stock: One of the primary advantages of the tenon saw is its ability to cut larger pieces of wood efficiently. With its coarse teeth and wide blade, it efficiently handles thick stock, ensuring straight, accurate cuts every time.

Task Comparison

Now that we’ve explored the individual strengths of the dovetail saw and the tenon saw, let’s conduct a detailed task comparison to highlight their differences:

Joinery Precision

- Dovetail Saw: Unmatched in precision joinery work, excelling in dovetail joints and delicate joinery.

- Tenon Saw: Proficient in creating tenon joints and mitre joints but may achieve a different level of delicacy than the dovetail saw.

Stock Size

- Dovetail Saw: Primarily suited for smaller stock and detailed work.

- Tenon Saw: Designed for more extensive stock, making it efficient for larger projects and substantial joinery.

Tooth Configuration

- Dovetail Saw: Features fine teeth with a higher TPI (teeth per inch) count, ideal for fine, intricate cuts.

- Tenon Saw: Boasts coarser teeth with a lower TPI count, optimized for cutting larger wood pieces efficiently.

- Dovetail and tenon saws are both hand saws commonly used in woodworking. Still, they have distinct differences in design and primary purposes. Here are the significant differences between the two:

Purpose

- Dovetail Saw: Dovetail saws are explicitly designed for making delicate and precise cuts, often used for cutting dovetail joints. These joints are commonly found in woodworking for joining pieces of wood at right angles, such as in drawers or boxes.

- Tenon Saw: Tenon saws, on the other hand, are primarily designed for cutting solid tenons, interlocking joints typically used in furniture and carpentry. Tenon joints are usually used in structural applications where strength and stability are essential.

Tooth Configuration

- Dovetail Saw: Dovetail saws typically have finer teeth with a higher tooth count per inch (TPI). The fine teeth allow for more precise and clean hardwood cuts, making them ideal for intricate joinery work.

- Tenon Saw: Tenon saws have coarser teeth with a lower TPI than dovetail saws. The coarser teeth are better suited for cutting through thicker pieces of wood quickly and efficiently when forming tenon joints.

Blade Length

- Dovetail Saw: Dovetail saws usually have shorter blades, typically 6 to 10 inches long. The shorter blade allows for better control and accuracy when cutting small joints.

- Tenon Saw: Tenon saws typically have longer blades, often 10 to 16 inches. The longer blade helps make longer and straighter cuts when cutting tenons or other similar joinery.

Back Design

- Dovetail Saw: Dovetail saws often have a thinner and less rigid back, which allows for greater flexibility and precision in making intricate cuts.

- Tenon Saw: Tenon saws typically have a thicker, more rigid back. This design provides stability and helps keep the saw blade straight when cutting through thicker pieces of wood.

Conclusion

The dovetail and tenon saw are indispensable assets to woodworkers, enabling them to achieve precision and strength in their creations.

Their differences in tooth configuration, blade length, and back design cater to specific woodworking needs, making them essential tools for anyone dedicated to the craft.

These saws exemplify how the right tool, designed with a specific purpose in mind, can significantly enhance the quality and craftsmanship of a woodworking project.