Hand saw teeth are the small, sharp, serrated projections or edges found along the cutting edge of a hand saw blade. When the saw is manually operated by pushing and pulling, these teeth are designed to efficiently cut through various materials, such as wood, plastic, or metal. The teeth’ arrangement, size, and shape can vary depending on the types of hand saw teeth and its intended purpose.

Here are some key aspects of hand saw teeth

1. Shape:

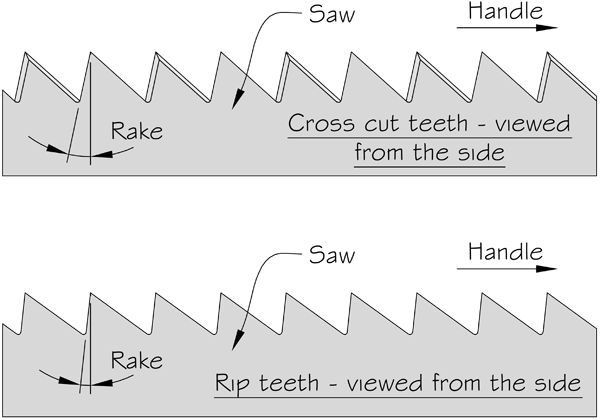

Hand saw teeth can come in various shapes, including crosscut and rip teeth. The teeth’ specific shape influences the saw’s efficiency in different cutting tasks.

2. Set:

The set of the teeth refers to their alternating angles to the saw blade. This alternating pattern creates a kerf, the width of the cut made by the saw. A proper tooth set is essential to prevent the saw from binding in the cut material.

3. TPI (Teeth Per Inch):

The TPI of a hand saw refers to the number of teeth found along one inch of the saw blade. Hand saws with higher TPI values typically have finer teeth and are suitable for making smoother, finer cuts in materials like wood. In contrast, lower TPI saws with more prominent teeth are better for faster, rougher cuts.

5. Rake Angle:

The rake angle is the angle at which the teeth are positioned in the cutting direction. It affects how the saw bites into the material. Positive rake angles are standard for crosscut saws, while rip saws typically have a zero or slightly negative rake angle.

Importance of selecting the correct type of hand saw teeth

Selecting the correct type of hand saw teeth is crucial for several reasons, as it directly impacts the efficiency, quality, and safety of your cutting tasks.

1. Efficiency: Different hand saw teeth are designed for specific cutting tasks. Selecting the correct teeth configuration ensures you can complete your cutting job more efficiently. For example, using a crosscut saw with fine teeth for precise cuts on the wood across the grain or selecting a rip saw with coarse teeth for ripping along the grain can significantly speed up your work.

2. Quality of Cut: The type of hand saw teeth you use affects the quality of the cut. Using the wrong teeth for a particular task can result in rough or jagged cuts, which may require additional finishing or sanding to achieve the desired smoothness. Selecting the appropriate teeth makes you more likely to achieve cleaner and more precise cuts.

3. Safety: Proper teeth selection contributes to safety. Using a saw with the wrong teeth for a specific material can lead to excessive binding, kickback, or damage to the saw or workpiece. For instance, trying to crosscut with a rip saw may cause the saw to jam or jump out of the cut, potentially causing injury. Selecting the correct teeth helps prevent such safety hazards.

4. Tool Longevity: Matching the type of hand saw teeth to the material you’re cutting also extends the lifespan of your saw. Using a saw with teeth designed for a specific task reduces wear and tear on the blade and teeth. Using the wrong saw for a job can lead to premature dulling and the need for more frequent replacements.

5. Material Preservation: When you choose the appropriate teeth for your hand saw, you minimize material wastage. For example, using a fine-toothed saw on expensive hardwood allows you to make precise cuts with minimal wood loss, ensuring that your materials go further and you make the most of your resources.

6. Productivity: The right type of hand saw teeth can significantly enhance your productivity. You’ll be able to complete tasks more quickly and accurately, saving time and improving overall efficiency.

7. Professional Results: Whether you’re a professional tradesperson or a DIY enthusiast, selecting the right-hand saw teeth ensures you achieve professional-quality results. This is particularly important for tasks like woodworking, where precision and aesthetics are crucial.

Rip-Cut Teeth

Rip-cut teeth are a specific type found on hand saws designed for cutting along the grain of wood or other materials. Here are some key characteristics and features of rip-cut teeth:

1. Shape: Rip-cut teeth typically have a chisel-like shape with a flat front face. This flat face allows them to engage with the wood fibers more effectively when cutting along the grain.

2. Tooth Orientation: Rip-cut teeth are usually oriented in a straight line along the saw blade. They don’t have an alternating pattern like crosscut teeth, designed for cutting across the grain.

3. Spacing: The spacing between rip-cut teeth is relatively wider than crosscut teeth. This design helps to quickly remove larger wood chips as the saw moves along the grain.

4. Rake Angle: Rip-cut teeth often have a zero or slightly negative rake angle, almost perpendicular to the saw blade. This orientation helps the teeth act as chisels that chisel out material along the grain.

5. Teeth Per Inch (TPI): Rip-cut saws generally have a lower TPI than crosscut saws. This lower TPI, with the more prominent teeth and wider spacing, makes rip-cut saws suitable for fast material removal along the grain.

6. Application: Rip-cut saws are primarily used for tasks like ripping boards, cutting lumber to width, and other jobs that involve following the natural grain direction of the wood. They excel at removing wood quickly and efficiently when you need to make long, straight cuts along the length of a board.

Rip-cut teeth are specifically designed to prevent the saw from binding and to efficiently remove wood fibers when cutting in the direction of the grain. Using a rip-cut saw for crosscutting or a crosscut saw for ripping can result in inefficient cutting, rough finishes, and potentially increased safety risks due to the saw’s tendency to bind.

Advantages and disadvantages of rip-cut teeth

Benefits of Rip-Cut Teeth:

1. Efficiency: Rip-cut teeth are highly efficient when cutting along the grain. Their design allows for fast material removal, making them ideal for tasks that involve making long, straight cuts in the direction of the wood’s natural grain.

2. Reduced Binding: Rip-cut teeth are less likely to bind or get stuck in the wood fibers when used for ripping tasks. The straight-line orientation and low or negative rake angle help prevent the saw from jamming during the cut.

3. Faster Cutting: Because of their wider spacing and larger teeth, rip-cut saws can cut through wood quickly. This speed is advantageous when making rough cuts or when efficiency is a priority.

4. Material Preservation: Rip-cut teeth are designed to remove material cleanly and efficiently along the grain, minimizing waste and preserving the quality of the remaining wood.

5. Straight Cuts: Rip-cut saws produce straight cuts along the grain, making them suitable for cutting boards to width or preparing lumber for joinery.

Disadvantages of Rip-Cut Teeth:

1. Limited Versatility: Rip-cut teeth are specialized for cutting along the grain. They must be better suited for crosscutting (cutting across the grain), which requires a different type of saw with crosscut teeth. This limitation means you may need multiple saws for different kinds of cuts.

2. Rough Finish: While rip-cut teeth excel at removing material quickly, they may leave a rougher surface finish compared to crosscut teeth, which are designed for smoother cuts across the grain. Additional sanding or finishing work may be required for specific projects.

3. Not for Precision: If you require precise, fine cuts or need to make cuts across the grain, there are better choices than rip-cut teeth. Their design may lead to less accuracy and a less refined result.

4. Potential Tearout: When using rip-cut teeth on certain woods with irregular grain patterns or prone to tear out, you may experience tear out or splintering along the cut line.

5. Skill Required: Using a rip-cut saw effectively requires skill and practice. Maintaining a straight line along the grain can be challenging, and deviations from the desired path may result in a less-than-straight cut.

Crosscut Teeth

Crosscut teeth are a specific type found on hand saws designed for cutting across the grain of wood or other materials. These teeth are optimized for making cuts perpendicular or diagonal to the natural grain direction of the material. Here are some key characteristics and features of crosscut teeth:

Shape: Crosscut teeth typically have a more pointed, chisel-like shape than rip-cut teeth. This shape allows them to slice through wood fibers more effectively when cutting across the grain.

Tooth Orientation: Crosscut teeth are arranged in an alternating pattern along the saw blade. This alternating pattern helps reduce the tendency of the saw to bind in the wood during the cut.

Spacing: The spacing between crosscut teeth is generally closer than rip-cut teeth. This design allows for finer cuts and smoother finishes on the cut material.

Rake Angle: Crosscut teeth often have a positive rake angle, meaning they are angled forward in the direction of the cut. This orientation helps the teeth act like knives that serve wood fibers cleanly when cutting across the grain.

Teeth Per Inch (TPI): Crosscut saws typically have a higher TPI than rip-cut saws. The higher TPI, finer teeth, and closer spacing make crosscut saws suitable for making precise, clean cuts across the grain.

Application: Crosscut saws are primarily used for tasks like crosscutting boards, trimming, making miter cuts, and other jobs that involve cutting across the grain of wood or other materials. They produce smooth, accurate amounts perpendicular to the wood’s natural grain direction.

Advantages of Crosscut Teeth

1. Precision: Crosscut teeth are excellent for making precise and clean cuts across the grain. They leave a smooth finish on the material and are ideal for woodworking tasks that require accuracy and fine craftsmanship.

2. Versatility: Crosscut saws are versatile and can handle various cutting tasks, including trimming, molding, and joinery, where clean and precise cuts are essential.

3. Reduced Tearout: Crosscut teeth are less likely to cause tear out or splintering when cutting across the grain than rip-cut teeth, essential for achieving a polished look in woodworking projects.

4. Smooth Finish: These teeth provide a smoother surface finish on the cut material, reducing the need for additional sanding or finishing work.

5. Clean Cuts: Crosscut saws are suitable for making cuts across knots or irregular grain patterns, producing clean and even results.

Disadvantages of Crosscut Teeth:

1. Slower Cutting: Crosscut saws may not be as efficient as rip-cut saws for removing material quickly, especially when making long cuts along the grain.

2. Binding Risk: Crosscut saws may be more prone to binding when cutting thick or dense materials than rip-cut saws, as they have finer teeth and a higher TPI.

Hybrid Teeth

Hybrid teeth are not a standard term or type found on hand saws. However, mixed teeth could refer to a combination of tooth configurations on a single saw blade or a saw designed to perform rip-cutting and crosscutting tasks effectively. Here’s a more detailed explanation:

1. Combination Blades:

Some saw blades are designed with a combination of rip-cut and crosscut teeth. These blades typically have alternating sections with different tooth configurations.

For example, a saw blade might have a team with rip-cut teeth followed by a section with crosscut teeth. This allows users to switch between the two styles by adjusting their cutting technique. Combination blades are versatile and can be helpful in general-purpose cutting.

2. Variable-Pitch Teeth:

Some modern hand saws have variable-pitch teeth, which means the pitch (spacing between teeth) changes along the length of the blade.

This design can make the saw more versatile, as it can handle both ripping and crosscutting tasks effectively. The varying pitch creates a hybrid tooth configuration that adapts to different cutting needs.

3. Multi-Purpose Saws:

Hand saws are also designed as multi-purpose or general-purpose saws. These saws may incorporate a tooth configuration that compromises rip-cut and crosscut teeth. While not specialized for either task, they aim to balance efficiency and precision, making them suitable for various cutting applications.

Hybrid teeth or hybrid saws can be advantageous for users who need a single saw that can handle a range of cutting tasks without switching between different saws. These hybrid configurations provide versatility while maintaining reasonable cutting efficiency and quality.

Japanese Pull Saw Teeth

Japanese pull saw teeth are a unique and distinctive feature of Japanese hand saws, designed for cutting with a pulling motion rather than a pushing motion like traditional Western saws.

These saws are highly regarded for their precision and ability to produce clean and accurate cuts in various woodworking and carpentry tasks. Here are the key characteristics of Japanese pull saw teeth:

1. Design: Japanese pull saw teeth are typically small, sharp, and closely spaced along the blade. The teeth are often ground into the blade rather than set like Western saw teeth. This design allows for a thinner, more flexible blade well-suited for detailed and intricate cuts.

2. Crosscut vs. Rip-Cut Teeth: Japanese pull saws come in two primary tooth configurations: crosscut teeth and rip-cut teeth.

- Crosscut Teeth: Crosscut teeth on Japanese pull saws have a series of small, alternating beveled teeth. These teeth are designed for cutting across the wood grain, providing a clean and smooth finish without tearout.

- Rip-Cut Teeth: Rip-cut teeth have more prominent, chisel-like teeth that are oriented in the direction of the cut. They are used for cutting along the grain and excel at quickly removing material in a straight line.

3. Pulling Motion: Japanese pull saws are designed to be pulled towards the user rather than pushed as in Western saws. This pulling motion allows for greater control and precision when making cuts. It also minimizes the risk of bending or breaking the thin blade.

4. Thin Kerf: Japanese pull saws typically have a thin blade, which results in a narrow kerf (the width of the cut). This thin kerf reduces material wastage and allows for fine, intricate cuts.

5. Clean Cuts: Due to their sharp teeth and pull-cutting action, Japanese pull saws are known for producing immaculate and splinter-free cuts, making them ideal for fine woodworking, joinery, and cabinetry.

6. Versatility: Japanese pull saws are versatile tools that can handle various cutting tasks, from delicate, precision work to rough cuts. They are used in woodworking, carpentry, and even for cutting plastic and soft metals.

7. Minimal Set: Unlike Western saws, which often have teeth set or bent to the sides, Japanese pull saw teeth have minimal or no set. This feature reduces the risk of the saw binding in the cut, which can be especially beneficial when making intricate cuts.

Fine Tooth vs. Coarse Tooth

Fine tooth and coarse tooth are terms used to describe the spacing and size of teeth on various cutting tools, including saws. Choosing between fine and coarse teeth depends on the specific cutting task and the desired outcome. Here’s a comparison of fine tooth vs. coarse tooth:

Fine Tooth:

1. Teeth Spacing: Fine-toothed tools have teeth closely spaced along the cutting edge. This means more teeth per inch (TPI), resulting in a higher tooth density.

2. Size of Teeth: The teeth on fine-toothed tools are generally smaller and shorter.

3. Cutting Precision: Fine-toothed tools are ideal for precision cutting tasks. They excel at producing clean, smooth cuts with minimal tear-out or splintering. Woodworkers often use fine-toothed saws for detailed woodworking projects and jobs requiring a high-quality finish.

4. Materials: Fine-toothed tools are suitable for cutting delicate materials such as hardwood, plywood, veneer, plastics, and metals, where precision is paramount.

5. Slower Material Removal: Fine-toothed tools tend to remove material more slowly than coarse-toothed tools because of their closely spaced teeth. They are not ideal for rapid material removal but are excellent for controlled and accurate cutting.

6. Examples: Fine-toothed tools include fine-tooth hand saws, coping saws, and fine-toothed jigsaw blades.

Coarse Tooth

1. Teeth Spacing: Coarse-toothed tools have teeth spaced farther apart along the cutting edge. This results in a lower TPI and lower tooth density.

2. Size of Teeth: Coarse-toothed tools typically have more extensive and prolonged teeth.

3. Cutting Speed: Coarse-toothed tools are designed for rapid material removal. They can quickly cut through thicker and tougher materials.

4. Rougher Finish: While coarse-toothed tools are efficient for fast cuts, they may leave a rougher finish compared to fine-toothed devices. Additional finishing work may be needed for a smoother surface.

5. Materials: Coarse-toothed tools are often used for cutting softwoods, construction lumber, rough timber, and materials where speed and efficiency are more important than a polished finish.

6. Examples: Coarse-toothed tools include crosscut hand saws, rip hand saws, pruning saws, and rough-cutting jigsaw blades.

Conclusion

The choice between fine and coarse tools, including saws, hinges on the specific cutting task and desired outcome. Fine-toothed tools offer precision and a smooth finish, making them ideal for delicate materials and detailed work.

Coarse-toothed agencies prioritize rapid material removal and are suited for more rigid materials but may result in a rougher finish. The proper tooth configuration is essential for achieving optimal results in various cutting applications.