In the world of woodworking, where precision and efficiency are paramount, the choice between tools can be the difference between a project’s success and its frustration.

Among the array of saws available, two fundamental players often find themselves in the spotlight: the cross-cut saw and the rip saw. Despite their shared association with woodworking, these two tools serve distinct purposes and possess unique characteristics that cater to different cutting requirements.

In this exploration of “Cross-cut saw vs Rip saw,” we will dive into the essential differences, applications, and considerations for each of these saws.

Whether you’re an experienced woodworker or a novice looking to expand your knowledge, understanding the distinctions between these saws is vital for achieving the precision and results you seek in your woodworking projects. Join us on this comparative journey as we unravel the nuances of cross-cut saws and rip saws.

Cross-cut and rip saws are two distinct hand saws designed for specific woodworking tasks. They differ in their tooth patterns, cutting actions, and purposes. Let’s introduce each of them:

Cross-cut Saw:

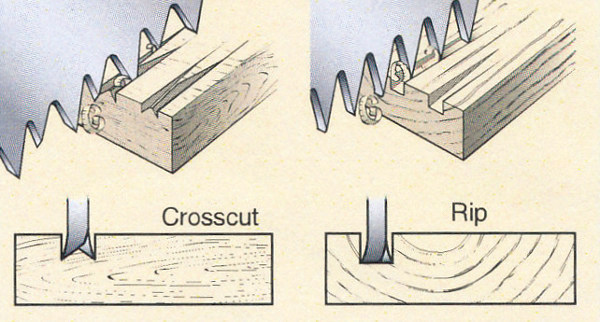

1. Purpose: Cross-cut saws are primarily used for cutting wood across the grain. This means they excel at making clean and precise cuts perpendicular to the wood’s natural fibers. Cross-cutting is often done to shorten boards or create pieces with specific dimensions.

2. Tooth Pattern: Cross-cut saws have teeth shaped like a series of minor, sharp points with beveled edges. These teeth are designed to serve wood fibers cleanly when cutting.

3. Cutting Action: When using a cross-cut saw, the teeth shear through the wood fibers at an angle, creating small chips and leaving a smoother surface on the cut edge. This action minimizes splintering.

4. Examples: Backsaws, panel saws, and tenon saws are examples of cross-cut saws. These saws are commonly used in fine woodworking and joinery.

Rip Saw:

1. Purpose: Rip saws are designed for cutting wood along the grain parallel to the natural fibers. They excel at quickly removing material in a straight line. Rip-cutting often transforms a rough board into narrower strips or planks.

2. Tooth Pattern: Rip saws have more chisel-like teeth with flat, unbeveled edges. These teeth are optimized for efficiently removing wood along the grain.

3. Cutting Action: When using a rip saw, the teeth act like miniature chisels, chipping away at the wood fibers in a straight line. This results in a rougher cut surface compared to cross-cut saws.

4. Examples: Handsaws like the carpenter’s rip saw or a dedicated rip panel saw are typical examples of rip saws. They are frequently used in carpentry and construction tasks involving breaking down large lumber pieces.

What are cross-cut teeth?

Cross-cut teeth are a specific type of tooth pattern found on saw blades, particularly on cross-cut saws. These teeth are designed for cutting wood across the grain, which means they are optimized for making clean and precise cuts perpendicular to the natural fibers of the wood.

Characteristics of cross-cut teeth include:

1. Beveled Edges: Cross-cut teeth typically have minor, sharp points with beveled edges. These slopes are angled to form cutting edges that are sharp and keen, allowing them to slice through wood fibers effectively.

2. Alternating Pattern: Cross-cut teeth are usually set in an alternating pattern, meaning that one tooth is angled slightly to the left, and the next is angled slightly to the right. This alternating configuration helps prevent the saw from binding in the wood during the cut.

3. Sharp Points: The pointed tips of cross-cut teeth are designed to initiate the cut by penetrating the wood fibers cleanly. As the saw is pushed or pulled through the wood, these points sever the fibers, resulting in a clean, smooth-cut surface.

4. Chip Ejection: Cross-cut teeth are also designed to create small chips or shavings as they cut through the wood. This chip ejection helps reduce the likelihood of the saw getting stuck in the cut and ensures a more efficient cutting action.

5. Clean Cuts: Due to their tooth geometry and cutting action, saws with cross-cut teeth are excellent for producing clean and precise cuts across the grain. They minimize splintering and tearing of the wood fibers, resulting in a smooth finish on the cut surface.

What are rip teeth?

Rip teeth, also known as rip-cut teeth, are a specific type of tooth pattern found on saw blades, particularly on rip saws. These teeth are designed for cutting wood along the grain, parallel to the natural fibers of the wood. Rip saws are optimized for making efficient and rapid cuts in a straight line through the wood.

Characteristics of rip teeth include:

1. Flat, Unbeveled Edges: Rip teeth have flat edges. Unlike cross-cut teeth, which have beveled edges for slicing across wood fibers, rip teeth have straight edges that act more like chisels.

2. No Set or Minimal Set: Rip teeth are often set straight across the saw blade or have a minimal set. This means the teeth are aligned straight and don’t alternate left and right like cross-cut teeth. The minimal or no set allows the teeth to cut wood fibers cleanly along the grain without creating significant waste.

3. Chisel-Like Cutting Action: When a rip saw with rip teeth is used, the teeth function like miniature chisels. They chip away at the wood fibers in a straight line, removing material efficiently and quickly.

4. Rougher Cut Surface: Because rip teeth are optimized for speed and material removal along the grain, the cut surface produced by a rip saw is typically rougher compared to the smooth, clean-cut surface produced by cross-cut teeth. This roughness is acceptable for many applications where the cut edge will be further processed or hidden.

5. Efficiency: Rip saws with rip teeth are excellent for quickly breaking down large pieces of lumber into narrower strips or planks. They are commonly used in carpentry, construction, and tasks where speed and material removal are the primary concerns.

What are cross-cut teeth with some rip teeth for?

Cross-cut teeth with some rip teeth refer to a hybrid tooth pattern on a saw blade that incorporates cross-cut and rip teeth elements. This combination of tooth patterns is designed to offer versatility in cutting various types of wood and performing various woodworking tasks.

The inclusion of rip teeth in a predominantly cross-cut pattern can provide the following benefits:

1. Versatility: The hybrid tooth pattern allows the saw to handle cross-cutting and rip-cutting tasks. This means you can use the same saw for tasks that require clean, precise cuts across the grain (cross-cutting) and tasks that involve cutting along the grain (ripping).

2. Efficiency: A hybrid tooth pattern may not be as efficient for rip-cutting as a dedicated rip saw with rip teeth, but it can still handle ripping tasks reasonably well. This versatility can be advantageous when you frequently switch between cutting directions.

3. Clean Cross-cuts: Cross-cut teeth ensure the saw can make clean and precise cross-cuts when needed. This is particularly useful for fine woodworking and joinery applications where a smooth finish is essential.

4. Rougher Rips: Although fewer rip teeth allow the saw to tackle rip-cutting tasks by effectively removing material along the grain. While the resulting cut may be smoother than that achieved with a dedicated rip saw, it can be sufficient for many applications.

5. Reduced Tearout: The cross-cut teeth on the saw blade can help minimize tear out (splintering or chipping) when making cross-cuts, even though some rip teeth are present. This combination can result in cleaner cross-cut surfaces.

Traditional Meets Modern

“Traditional Meets Modern: Cross-cut Saw vs. Rip Saw”

In the world of woodworking and carpentry, there’s a timeless synergy between traditional hand tools and modern innovations. Cross-cut and rip saws with distinct characteristics exemplify this balance of tradition and modernity.

Traditional Cross-cut Saw:

· Design: Traditional cross-cut saws are hand tools with wooden handles and steel blades. These saws often feature a classic, time-tested design that has been refined over centuries.

· Purpose: The primary purpose of a traditional cross-cut saw is to make clean, precise cuts across the grain of wood. It embodies the essence of fine craftsmanship, ideal for creating joints, cabinetry, and woodworking projects that demand accuracy.

· Technique: Using a traditional cross-cut saw requires skill and precision. Woodworkers rely on their experience and keen eyes to achieve the desired results.

· Connection to Tradition: Traditional cross-cut saws connect modern woodworkers to the rich history of craftsmanship. They evoke a sense of tradition and craftsmanship passed down through generations.

Modern Cross-cut Saw:

· Design: Modern cross-cut saws maintain the fundamental design of their traditional counterparts but often incorporate ergonomic handles and advanced materials for increased comfort and durability.

· Technology: Some modern cross-cut saws may feature tooth patterns optimized for specific applications, enhancing their cutting efficiency. Additionally, power tools like circular saws with cross-cut blades are available for those who prefer the speed and precision of modern technology.

· Versatility: Modern cross-cut saws can be adapted for various cutting tasks by changing blades or adjusting settings, making them versatile tools suitable for professionals and DIY enthusiasts.

Traditional Rip Saw:

· Design: Traditional rip saws share the classic wooden handle and steel blade design with their cross-cut counterparts. However, their rip teeth configuration sets them apart.

· Purpose: The primary purpose of a traditional rip saw is to cut along the grain of the wood efficiently. This makes it indispensable for tasks like dimensioning lumber and producing straight-edged boards.

· Technique: Like traditional cross-cut saws, using a traditional rip saw requires a skilled technique to ensure straight, efficient cuts.

· Heritage: Traditional rip saws carry the heritage of centuries-old woodworking practices, embodying the essence of craftsmanship in their design and function.

Modern Rip Saw:

· Design: Modern rip saws retain the core elements of their traditional counterparts but may incorporate ergonomic features, advanced materials, and blade innovations for enhanced performance.

· Technology: Some modern rip saws feature innovations such as anti-kickback mechanisms and laser guides for improved safety and precision. Power tools like table and band saws are popular for modern rip-cutting tasks.

· Efficiency: Modern rip saws, both hand and power tools, are designed for efficiency and accuracy, making them indispensable in modern woodworking shops.

Specialty Saws

Specialty saws are designed for specific tasks or materials, each tailored to provide optimal performance for particular cutting requirements. These specialized saws often have unique features, blade designs, or cutting mechanisms to excel in their intended applications. Here are some common types of specialty saws:

1. Japanese Pull Saw (Nokogiri): Japanese pull saws are known for their precision and fine cutting abilities. They have thin, replaceable blades with teeth set to cut on the pull stroke. They are excellent for woodworking tasks that demand accuracy, such as joinery and intricate cuts.

2. Dovetail Saw: Dovetail saws are designed specifically for cutting dovetail joints, a common type of joint in woodworking. They have a thin blade with fine teeth and a reinforced spine to ensure straight and precise cuts.

3. Coping Saw: Coping saws have a thin, narrow blade stretched in a U-shaped frame. They are primarily used for making curved and intricate cuts, such as coping joints for moldings or trim work.

4. Keyhole Saw (Jab Saw): Keyhole saws are designed for cutting small, precise holes or curves in various materials, including wood, drywall, and plastic. They have a pointed blade that can be inserted into a small opening, making them useful for cutting holes in locks or electrical boxes.

5. Flush-Cut Saw: Flush-cut saws are used for trimming dowels, plugs, or other protruding materials flush with the surface of a workpiece. They have a flexible blade that can cut without damaging the surrounding surface.

6. Cable Saw: Cable saws consist of a wire cable with cutting teeth, often used for cutting pipes, tubing, or branches in tight spaces where other saws cannot reach.

7. Veneer Saw: Veneer saws are designed for slicing thin sheets of wood veneer cleanly and accurately. They have a fine-toothed blade and a stiff, narrow design to prevent bending or tearing of the veneer.

8. Carbide-Tipped Saw Blade: While not a separate saw, carbide-tipped saw blades are used on circular saws or miter saws to cut through hard materials like metal or masonry. The carbide teeth provide extended durability and cutting efficiency.

9. Bone Saw: Bone saws are designed for butchering and cutting through bones, making them essential tools in meat processing and culinary arts.

10. Hacksaw: Hacksaws are versatile hand saws with a fine-toothed blade, primarily used for cutting metal pipes, rods, and bars. They are commonly used in plumbing and metalworking.

11. Backsaw: Backsaws are specialized hand saws with a reinforced back edge, making them suitable for precise joinery work. Types include tenon saws and dovetail saws.

12. Bow Saw: Bow saws have a bow-shaped frame and are designed for cutting green wood, such as branches and logs. They are popular choices for outdoor and woodworking tasks.

How do you sharpen a cross-cut saw?

Sharpening a cross-cut saw is a meticulous process that involves filing the teeth to ensure they are sharp and correctly set. This process requires the right tools and a steady hand. Here are the steps to sharpen a cross-cut saw:

Tools and Materials Needed:

- 1. Cross-cut saw vise or clamps to secure the saw.

- 2. Flat file (mill file) with an appropriate size and cut (usually a single-cut file).

- 3. Triangular saw file (tooth file).

- 4. Saw set tool (for adjusting the set of teeth).

- 5. A saw jointer (optional for jointing the teeth).

Step-by-Step Guide:

1. Secure the Saw:

· Place the cross-cut saw in a specialized saw vise or use clamps to secure it firmly. The saw should be stable and not wobble during sharpening.

2. Inspect the Teeth:

· Examine the teeth to identify any damaged or missing ones. Replace or repair any damaged teeth before proceeding with sharpening.

3. Joint the Teeth (Optional):

· If the saw teeth are uneven or dull over time, you can use a saw jointer to level them. A jointer is a specialized tool with flat and angled sides that allows you to maintain uniform tooth height. Run the jointer along the teeth to even them out.

4. Set the Saw Teeth:

· Use a saw set tool to adjust the set of the teeth. Cross-cut saws typically have alternating teeth, with one set to the right and the next to the left. The set creates a kerf wide enough to prevent binding during cutting.

· Follow the manufacturer’s instructions for the saw set tool, selecting the appropriate tooth set and adjusting the tool to match the saw’s tooth spacing.

· Place the tool on each tooth and squeeze the handles to bend the tooth in the desired direction. Ensure consistent set across all teeth.

5. Sharpen the Teeth:

- · Use a flat file to sharpen the teeth. Ensure you use the appropriate size and cut of file for your saw.

- · File each tooth individually, maintaining a consistent angle and pressure. File in one direction, away from you, and avoid back-and-forth motions.

- · Pay attention to the bevel angle of the teeth. The bevel angle should remain uniform across all teeth.

- · Count the number of strokes on each tooth to ensure even sharpening.

6. Check for Sharpness:

· After sharpening all teeth, carefully run your finger over the teeth to check for sharpness. Be cautious not to cut yourself. Sharp teeth should feel like fine, pointed needles.

7. Final Touches:

· Remove any burrs or filings left on the teeth using a saw file or a deburring tool.

8. Clean and Oil:

· Clean the saw blade to remove any filings or debris. Lubricate the blade with a thin layer of oil to prevent rust.

Cost Of Cross-cut saw vs. rip saw.

Here’s a general overview of the cost differences between these types of saws:

Cross-cut Saws:

1. Handheld Cross-cut Saws: Traditional handheld cross-cut saws, typically used for fine woodworking, can range in price from $20 to $200 or more. The cost varies based on factors such as the quality of materials, blade design, and brand reputation.

3. Power Tools: If you’re considering a power tool like a circular saw or miter saw with a cross-cut blade, the cost can range from $50 for entry-level models to several hundred dollars or more for professional-grade equipment.

Rip Saws:

1. Handheld Rip Saws: Similar to handheld cross-cut saws, traditional handheld rip saws are available at various price points. Prices typically start around $20 and can go up to $200 or more, depending on the quality and brand.

2. Specialty Rip Saws: Specialty rip saws designed for specific rip-cutting tasks, such as resawing or cutting along the grain, may have varying costs.

3. Power Tools: Power tools like table and band saws are often used for rip-cutting tasks. These tools vary significantly, with entry-level models starting at around $200 and professional-grade models costing several thousand dollars or more.

Conclusion

In conclusion, sharpening a cross-cut saw is a critical skill for woodworkers and artisans to maintain its effectiveness and prolong its lifespan. Properly sharpened saw teeth are essential for making clean and accurate cuts across the grain of wood.