Precision and versatility are paramount in the woodworking and DIY projects. Whether crafting a custom piece of furniture, renovating your home, or embarking on an artistic endeavor.

Among the arsenal of tools available to artisans and enthusiasts, the jigsaw stands out as a versatile and indispensable cutting tool. Its ability to maneuver through curves, intricate patterns, and tight spaces makes it a valuable asset in any workshop.

The jigsaw, also known as a saber saw or scroll saw, has been a staple in the toolbox of professionals and hobbyists alike for decades.

This versatile power tool is designed to make intricate and precise cuts in various materials, including wood, metal, and plastic. However, one intriguing question often arises when working with a jigsaw: How thick can a jigsaw cut?

‘Importance of knowing jigsaw cutting capabilities

A thorough understanding of your tools is paramount in woodworking, construction, and DIY projects. One such tool that often takes center stage in various projects is the jigsaw.

It’s a versatile cutting tool that can tackle many materials and shapes, making it a go-to choice for artisans and enthusiasts. However, knowing a jigsaw’s cutting capabilities cannot be overstated. Here are some compelling reasons why:

Safety First: One of the foremost reasons for understanding a jigsaw’s cutting capabilities is safety. Attempting to cut materials that exceed the tool’s capacity can lead to accidents and injuries. Knowing the limits of your jigsaw helps you make informed decisions about the materials and thicknesses you can safely work with, minimizing the risk of mishaps.

Optimal Performance: Each jigsaw model and blade type has its own set of limitations. Understanding these limitations ensures that you use your jigsaw to its full potential.

Project Planning: Knowing the cutting capabilities of your jigsaw is essential for effective project planning. It allows you to choose the right tool for the job, ensuring that your project progresses smoothly.

Whether you’re cutting through thin plywood, thick hardwood, or other materials, having this knowledge helps you select the appropriate jigsaw model, blade type, and cutting technique.

Material Selection: Different jigsaw models are designed for different tasks and materials. Knowing your jigsaw’s capabilities empowers you to select the materials for your project.

This is particularly crucial when working on intricate or specialized projects where the choice of material can significantly impact the outcome.

Efficiency and Precision: When you know your jigsaw’s limits, you can work more efficiently and precisely. You can plan your cuts, adjust your cutting technique, and choose the right Blade for the job, contributing to better results and reduced frustration.

Cost-Efficiency: Using a jigsaw within its cutting capabilities can save you money in the long run. Avoiding costly mistakes, such as blade breakage or tool damage, ensures that your investment in the tool remains sound and that you won’t need to replace or repair it prematurely.

Skill Development: Understanding a jigsaw’s cutting capabilities is integral to skill development for artisans and DIY enthusiasts. It enables you to expand your knowledge and abilities, pushing the boundaries of what you can achieve with the tool and taking on more complex and challenging projects over time.

Factors Affecting Jigsaw Cutting Thickness

When using a jigsaw for cutting various materials, understanding the factors influencing cutting thickness is crucial for achieving precise and successful results.

Jigsaw cutting capabilities depend on a combination of factors, and being aware of these variables can help you make informed decisions in your woodworking or DIY projects. Below, we explore the key factors that affect jigsaw cutting thickness:

Jigsaw Type and Model

Different jigsaw models are designed for various applications. Some are built for light-duty tasks, while others are more robust and can handle thicker materials. Understanding your jigsaw’s specifications and capabilities is essential.

Blade Type and Quality

The type and quality of the Blade you use play a significant role in determining cutting thickness. Blades are designed for specific materials and thicknesses.

Motor Power

The power of the jigsaw’s motor affects its ability to cut through thick materials. High-powered jigsaws can handle thicker materials more efficiently than lower-powered ones. Consider the motor’s wattage and amperage when selecting a jigsaw.

Material Type and Hardness

The type of material you intend to cut significantly impacts the jigsaw’s cutting thickness. Softer materials like plywood and plastic are easier to cut through. At the same time, hardwoods and metals may require more power and a specific blade type.

Feed Rate and Cutting Speed

The speed at which you move the jigsaw through the material, known as the feed rate, affects the thickness you can cut. Slower feed rates may allow for thicker cuts, while faster speeds are suitable for thinner materials.

Blade Sharpness

A sharp blade is essential for efficient cutting. Dull blades can need help to cut through even thin materials, and they may wander off the intended path, leading to imprecise cuts.

Cutting Technique

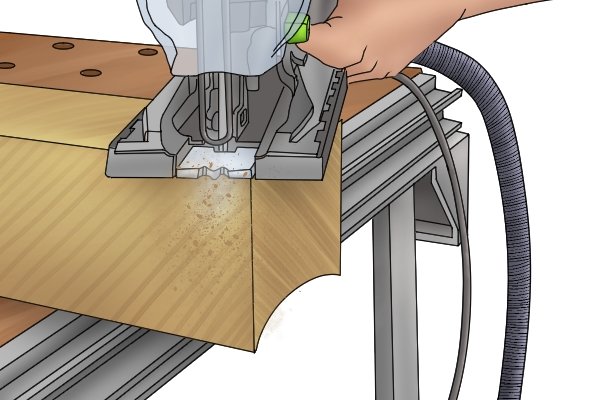

Your cutting technique plays a vital role in achieving the desired thicknesses. Maintaining a steady hand, following marked lines, and properly supporting the material can significantly affect your cuts’ quality and thickness.

Workpiece Stability

The stability of the workpiece can affect cutting thickness. Ensure the material is firmly secured to prevent vibrations or movement leading to uneven or thicker cuts.

Depth Adjustment and Beveling

Many jigsaws come with depth adjustment and beveling features. Adjusting the cutting depth and bevel angle can help you achieve precise and consistent cut thickness.

Material Thickness vs. Blade Length

It’s essential to consider the relationship between the material’s thickness and the jigsaw blade’s length. If the Blade takes longer to reach through the material, you won’t be able to cut it completely.

Jigsaw Power and Speed Settings

A jigsaw’s power and speed settings are crucial when cutting thick materials. These settings are instrumental in determining the cut’s quality and impact the operator’s safety and the cutting process’s overall efficiency. Let’s delve into the role of power and speed settings in cutting thick materials:

Cutting Efficiency

When cutting thick materials, the power of the jigsaw’s motor becomes essential. Higher-powered jigsaws can maintain cutting speed and accuracy even with dense materials like hardwoods or metals. A powerful motor ensures the Blade can penetrate and move through the material without slowing or bogging down.

Reduced Strain on the Tool

Thick materials can significantly strain the jigsaw’s motor and Blade. An appropriate power setting allows the tool to handle the resistance more effectively, reducing wear and tear on the jigsaw and prolonging its lifespan.

Precision and Control

Speed settings on a jigsaw can be adjusted to match the thickness and hardness of the material. Lower speeds are typically suitable for thicker and denser materials, as they provide better control and precision. Slower speeds prevent the Blade from wandering or overheating, leading to cleaner and more accurate cuts.

Minimized Blade Heat Buildup

Cutting through thick materials can generate heat due to friction between the Blade and the material. Running the jigsaw at a lower speed reduces the heat buildup, which is especially important when cutting plastics or laminates that can melt or deform when overheated.

Safety and Control

Thick materials can be more challenging to cut, potentially causing the jigsaw to kick back or become difficult to control.

Blade Longevity

Using the correct power and speed settings can significantly extend the life of your jigsaw blades. Operating at high speeds on thick materials can cause blades to wear out quickly, leading to frequent replacements. Adjusting the settings to match the material’s thickness and hardness helps preserve blade sharpness and durability.

Reduced Tear-Out and Splintering

Lower speeds are particularly beneficial when cutting materials like plywood, laminates, or veneers. They help reduce tear-out and splintering on the cut surface, resulting in cleaner and more aesthetically pleasing edges.

Maximum Cutting Thickness for Common Jigsaw Blades

The maximum cutting thickness for standard jigsaw blades can vary depending on the blade type, the cut material, and the specific jigsaw model used. Here are some general guidelines for the maximum cutting thickness for common jigsaw blade types:

Wood Cutting Blades

- T-shank wood-cutting blades are commonly used for cutting wood with a jigsaw. These blades are available in various lengths and tooth configurations.

- For softwoods like pine or cedar, jigsaw blades can typically cut up to 2 inches (50 mm) in thickness.

- The maximum cutting thickness may be around 1 inch (25 mm) for hardwoods such as oak or maple.

- When using specialized wood-cutting blades with more prominent teeth or aggressive designs, you may be able to cut thicker wood. Still, it’s essential to consider the Blade’s specifications and the jigsaw’s power.

Metal Cutting Blades

Jigsaw blades designed for cutting metal, such as mild steel or aluminum, are typically thinner and have delicate teeth. These blades can generally cut metal up to 3/16 inch (4.75 mm) in thickness. Some heavy-duty metal-cutting blades may handle slightly thicker metal. Still, it depends on the Blade’s design and the jigsaw’s power.

Plastic and Laminate Blades

- Blades designed for cutting plastics, acrylics, and laminates are available and have particular tooth patterns to prevent melting and chipping.

- These blades typically cut materials up to 1/2 inch (12.7 mm) thick. However, thicker plastics may require slower cutting speeds and specialized blades.

- The maximum cutting thickness depends on the specific material being cut. For wood and metal, the guidelines mentioned above generally apply. For plastic, it’s similar to plastic-specific blades, around 1/2 inch (12.7 mm).

Specialty Blades

Some specialty jigsaw blades are designed for cutting curves, fine detail work, or ceramic tiles. These blades have varying maximum cutting thicknesses based on their intended use.

Tips for Achieving Maximum Cutting Thickness

Achieving maximum cutting thickness through a jigsaw requires careful planning, equipment, and proper technique. Here are some tips to help you cut thicker materials effectively:

Choose the Right Blade

Select a jigsaw blade designed for the material you intend to cut. Blades come in various types: wood, metal, plastic, and other materials. Choose one with the appropriate tooth pattern and TPI (teeth per inch) for the task.

Use a High-Quality Blade

Invest in high-quality blades with sharp teeth. Dull blades can lead to uneven cuts, increased resistance, and wear.

Slow Down the Cutting Speed

When cutting thicker materials, lower the jigsaw’s speed setting. Slower cutting speeds reduce friction and heat buildup, leading to cleaner cuts and preventing Blade overheating.

Secure the Material

Ensure the material you’re cutting is firmly clamped or held in place. Stability is crucial to prevent vibrations and maintain control over the jigsaw.

Make Multiple Passes

Consider making multiple passes when dealing with materials that exceed the jigsaw’s maximum cutting thickness. Cut through the material, retract the jigsaw, and repeat until you’ve cut through.

Plan Your Cut

Mark your cutting line clearly and precisely. Take your time to plan the cut, especially when working with thicker materials, to ensure accuracy.

Use Lubrication (For Metal)

If you’re cutting metal, using cutting fluid or a lubricant can help reduce heat and friction, prolonging the Blade’s life and improving the cut’s quality.

Support the Cut

Provide additional support to the material, significantly when cutting thicker or denser materials. Placing a piece of sacrificial material underneath can help prevent tear-out on the underside of the cut.

Practice Patience

Cutting thick materials with a jigsaw may take longer compared to thinner materials. Be patient and maintain a steady hand to ensure accuracy and safety.

Test on Scrap Material

Before cutting your workpiece, make test cuts on the same type and thickness of scrap material. This allows you to fine-tune your technique and settings for the best results.

Maintain Your Jigsaw

Regularly check and maintain your jigsaw. Ensure the Blade is securely installed, the motor is in good condition, and all adjustments function correctly.

Consider Alternative Tools

For highly thick materials that exceed the capabilities of a jigsaw, consider using alternative tools such as a circular saw, reciprocating saw, or bandsaw.

Upgrading Jigsaw for Increased Thickness

Upgrading a jigsaw for increased cutting thickness involves enhancing its performance and capabilities to handle thicker materials more effectively. Here’s a brief note on how to upgrade a jigsaw for this purpose:

Choose a More Powerful Jigsaw

Consider upgrading to a jigsaw with a higher-powered motor. A more powerful motor can handle thicker materials with less strain and greater efficiency.

Variable Speed Control

Opt for a jigsaw model that offers variable speed control. This feature allows you to adjust the cutting speed to match the thickness and type of material you’re working with.

Use Specialized Blades

Invest in specialized jigsaw blades designed for cutting thick materials. These blades typically have more prominent teeth and can withstand the demands of thicker wood, metal, or plastic.

Blade Compatibility

Ensure that the upgraded jigsaw is compatible with various blade types and sizes. This versatility lets you choose the most suitable Blade for the specific task.

Orbital Action

Some advanced jigsaw models offer orbital action, which speeds up cutting and provides more aggressive cutting in thicker materials.

Depth Adjustment

Choose a jigsaw with precise depth adjustment settings. This feature enables you to accurately set the desired cutting depth, which is crucial for cutting thicker materials.

Stability and Ergonomics

Upgrade to a jigsaw with enhanced stability features, like a robust baseplate and ergonomic design. A stable jigsaw allows for better control and accuracy when cutting thicker materials.

Laser Guide or LED Light

Some jigsaw models have built-in laser guides or LED lights that help you follow your cutting line more accurately, even in thicker materials.

Dust Extraction System

Consider a jigsaw with a built-in dust extraction system to clean your workspace and reduce debris buildup when working with thicker materials.

Additional Accessories

Explore accessories and attachments that can improve your jigsaw’s performance, such as Blade and parallel guides, which can be particularly useful when cutting thicker stock.

Conclusion

In exploring the cutting capacities of jigsaw tools, it has become evident that the thickness of material a jigsaw can cut through is largely dependent on various factors including the blade type, the power of the motor, and the material being cut.

Generally, jigsaws are capable of cutting through materials ranging from about 1.5 to 3 inches in thickness. However, with the right blade and sufficient power, some jigsaws can tackle materials up to 5.5 inches thick.

The blade is a critical component in determining the cutting capacity of a jigsaw. Blades come in different types, lengths, and teeth configurations, each designed for specific materials and thicknesses.

For instance, longer blades with fewer teeth per inch (TPI) are more suited for making rough cuts through thicker materials, while shorter blades with higher TPI are ideal for making cleaner cuts through thinner materials.