When tackling DIY projects involving plastic materials, one crucial question often arises: “What jigsaw blade to cut plastic?” Selecting the right blade for your jigsaw can make all the difference in achieving clean, precise cuts while ensuring your safety.

This guide will dig into the different sorts of jigsaw blades available and provide valuable insights on choosing the most suitable one for your plastic-cutting needs. Whether you’re a seasoned DIY enthusiast or just starting, understanding the nuances of jigsaw blades for plastic is essential for a successful and efficient project. Let’s explore the world of jigsaw blades and unravel the secrets to achieving smooth and accurate plastic cuts.

Types of Jigsaw Blades

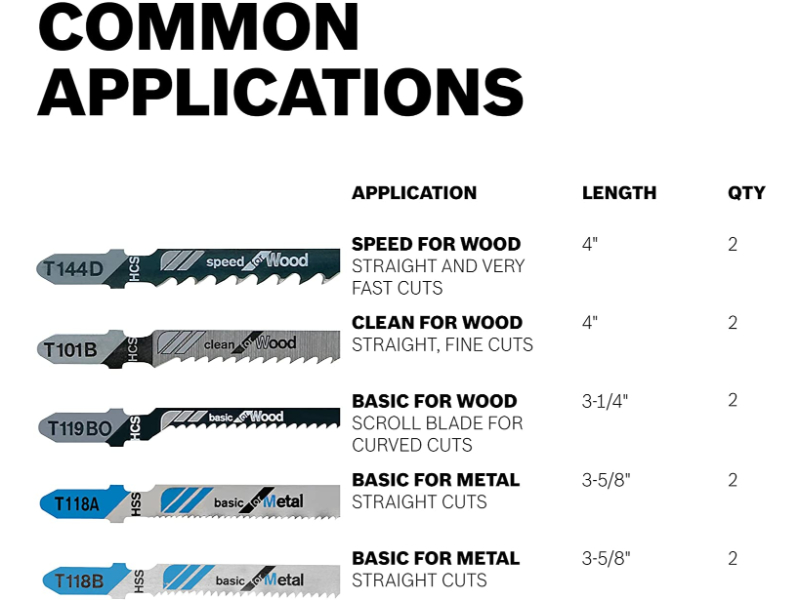

Jigsaw blades come in various types and designs, each suited for specific materials and cutting tasks. Here are some common types of jigsaw blades:

Wood-Cutting Blades

- Clean-Cut Blades: Designed for smooth and clean cuts in softwoods, hardwoods, plywood, and other wooden materials.

- Fast-Cut Blades: Ideal for rapid cutting in softwoods and construction lumber, featuring more prominent, aggressive teeth.

Metal-Cutting Blades

- High-Speed Steel (HSS) Blades: Suitable for cutting thin metal sheets, aluminum, and non-ferrous metals with fine teeth for precision.

- Bi-Metal Blades: Designed to cut thicker metals like steel and iron, with teeth combining high-speed steel and a flexible backing for durability.

- Carbide-Tipped Blades: Featuring carbide teeth for cutting through hard metals like stainless and hardened steel, offering long-lasting performance.

Plastic-Cutting Blades

- Plastic-Cutting Blades: These blades have fine teeth and are designed to minimize melting and chipping when cutting plastic materials like PVC, acrylic, and polycarbonate.

Tile-Cutting Blades

- Diamond-Coated Blades: Tile-cutting blades have a diamond-coated edge for cutting ceramic, porcelain, and glass tiles, providing precise and chip-free cuts.

Fiber-Cement Blades

- Fiber-Cement Blades: Designed for cutting fiber cement boards and siding, with durable teeth that resist wear and extend blade life.

Scrolling Blades

- Scrolling Blades: These blades have a narrow, fine-toothed design for making intricate curved cuts in wood, plastics, and thin metals, commonly used for detailed woodworking and crafts.

Reverse-Tooth Blades

- Reverse-Tooth Blades: Ideal for clean cuts in veneered plywood and laminates, with teeth pointing downward on the bottom edge to reduce splintering on the top surface of the material.

Downcut Blades

- Downcut Blades: Suitable for cutting laminates and melamine, featuring teeth that cut in a downward direction to prevent splintering on the bottom surface of the material.

Progressive-Tooth Blades

- Progressive-Tooth Blades: These blades have varying tooth sizes along the length of the blade, reducing vibration and providing smoother cuts in wood and metal.

T-Shank and U-Shank Blades

- Blades are available in two shank types: T-Shank and U-Shank. Using the correct shank type for your jigsaw is essential, as they are not interchangeable.

Specialty Blades

- Special jigsaw blades are designed for specific applications, such as curved cuts, plunge cuts, and laminate trimming.

When selecting a jigsaw blade, consider the material you’ll be cutting and the type of cut you need to make. Using the right blade for the job ensures cleaner cuts, faster progress, and extends the life of your jigsaw blade. Always follow the manufacturer’s recommendations and guidelines for blade selection and use.

Characteristics of a Suitable Jigsaw Blade for Plastic

A suitable jigsaw blade for cutting plastic should possess specific characteristics to ensure clean and precise cuts while minimizing the risk of melting or chipping. Here are the key characteristics of a suitable jigsaw blade for plastic:

Tooth Design: A blade designed for plastic cutting should have fine teeth with minimal spacing between them. This design reduces the chances of chipping and melting by minimizing friction and heat buildup during the cut.

Material Composition: Plastic-cutting Blades are often made of high-carbon steel (HCS) or high-speed steel (HSS). Some blades, such as Teflon, may have a special coating to reduce heat generation and friction.

Tooth Geometry: The teeth of the blade may have a progressive or wavy tooth pattern. This design helps prevent the blade from binding and provides a smoother, controlled cut.

Tooth Count: Blades designed for plastic cutting typically have a higher tooth count (TPI), often 12 to 24 teeth per inch—a higher TPI results in finer cuts and less heat generation.

Gullet Shape: Look for blades with deep gullets or spaces between the teeth. These gullets help remove plastic chips and debris during the cut, preventing clogging and overheating.

Tang Shape: Ensure the blade has the correct shank shape (T-Shank or U-Shank) that matches your jigsaw’s blade holder.

Blade Length: The length of the sharp edge ought to be sufficient for your specific cutting task. Using a blade long enough to extend through the material and provide stability during the cut is essential.

Blade Width: The edge width should match the desired cut width. Wider blades provide stability and may reduce the risk of wandering during the cut.

Cooling Slots: Some high-quality plastic-cutting blades feature slots or holes along the blade’s body to dissipate heat and prevent overheating.

Compatibility: Ensure that the blade is compatible with your jigsaw model. Jigsaw blades come in T-Shank or U-Shank designs, and not all blades fit every jigsaw.

When cutting plastic, choosing the right blade and using proper techniques is essential to minimize the risk of chipping, melting, or rough edges. Always follow safety precautions and wear appropriate personal protective equipment, including safety glasses, when working with power tools.

Tips for Choosing the Right Jigsaw Blade

Choosing the right jigsaw blade is crucial for achieving clean and efficient cuts in various materials. Here are some tips to help you select the appropriate jigsaw blade for your specific cutting needs:

- Consider the Material: Identify the type of material you’ll be cutting. Different materials require different blade types. Common materials include wood, metal, plastic, ceramic tile, and laminate.

- Check the Blade Compatibility: Ensure that the jigsaw blade you choose is compatible with your jigsaw model. Jigsaw blades come in T-Shank and U-Shank varieties; not all blades fit every jigsaw.

- Select the Right Blade Type: Choose a blade specifically designed for the material you’re working with. For example:

- Wood: Use blades with fine teeth for smooth cuts in wood.

- Metal: Opt for metal-cutting blades with the appropriate tooth design (fine teeth for thin metal, coarser teeth for thicker metal).

- Plastic: Select blades with fine teeth and minimal spacing to minimize melting and chipping.

- Tile: Use diamond-coated blades for cutting ceramic or glass tiles.

- Laminate: Choose blades with fine teeth and an anti-splinter insert for clean laminate cuts.

- Tooth Count (TPI): Consider the blade’s tooth count or teeth per inch (TPI). Higher TPI blades provide smoother cuts in materials like wood, while lower TPI blades are better for faster cuts in softer woods and construction lumber.

- Tooth Design: Different blade designs cater to various cutting tasks. Some examples include:

- Clean-Cut Blades: Fine teeth for smooth, splinter-free cuts in wood.

- Progressive-Tooth Blades: Varying tooth sizes to reduce vibration and improve control.

- Reverse-Tooth Blades: Teeth pointing downward to prevent splintering on the top surface of materials.

- Downcut Blades: Teeth that cut downward, reducing splintering on the bottom surface.

- Blade Length: Ensure the blade length is appropriate for your cutting task. It should extend beyond the material you’re cutting by a sufficient margin to provide stability and control.

- Cooling Slots or Holes: Some blades feature cooling slots or holes along their length. These help dissipate heat and prevent overheating during prolonged cuts.

- Coatings or Materials: Consider blades with special coatings or materials, such as Teflon-coated or carbide-tipped blades. These coatings can reduce friction and heat, enhancing blade longevity and performance.

- Budget and Quality: While cost can be a factor, investing in high-quality blades can lead to cleaner cuts and longer blade life. Quality blades are less likely to bend, flex, or become dull quickly.

- Test on Scrap Material: If you need help deciding which blade to use, conduct a test cut on a scrap piece of the same material to evaluate the blade’s performance and adjust your settings if necessary.

How to Cut Plastic with a Jigsaw?

Cutting plastic with a jigsaw can be straightforward if you follow the proper steps and use the appropriate blade. Here’s how to cut plastic with a jigsaw:

Materials and Tools:

- Plastic sheet or material

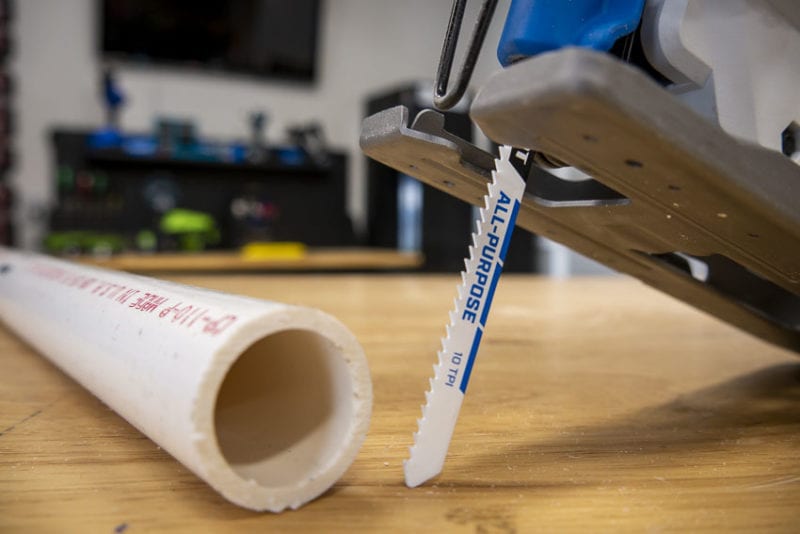

- Jigsaw with a fine-toothed blade designed for plastic

- Safety glasses or goggles

- Hearing protection

- Clamps (optional)

- Pencil or marker

- Straightedge or guide

- Workbench or sawhorses

Procedure:

- Mark Your Cutting Line:

- Using a pencil or marker, measure and mark the cutting line on the plastic sheet. Ensure your measurements are accurate, and use a straightedge or guide to create a straight cutting line.

- Secure the Workpiece (Optional):

- If the plastic sheet is small or prone to moving during the cut, you can use clips to tie it to a workbench or sawhorse. This helps ensure stability and accuracy.

- Select the Right Blade:

- Choose a jigsaw blade specifically designed for cutting plastic. These blades typically have fine teeth and minimal spacing to reduce friction, melting, and chipping. Ensure the blade is securely installed in your jigsaw.

- Set the Jigsaw Speed:

- Adjust the jigsaw’s speed settings to a moderate level. Plastic does not require high-speed cutting, and a moderate speed helps prevent overheating and melting.

- Position the Jigsaw:

- Position the jigsaw blade just outside the cutting line on the plastic sheet. Ensure the jigsaw’s base plate is flat against the plastic’s surface.

- Start the Jigsaw:

- Hold the jigsaw securely with both hands, keeping your fingers away from the blade. Start the jigsaw and allow it to reach full speed before cutting.

- Make the Cut:

- Begin cutting along the marked line, following your guide. Maintain a steady and controlled pace, and let the jigsaw blade do the work without applying excessive pressure. Keep the jigsaw’s base plate flat on the plastic to prevent tilting.

- Complete the Cut:

- Keep cutting until you arrive at the finish of the noticeable line. Ensure that the jigsaw blade exits the plastic cleanly to avoid splintering.

- Power Off and Clear Debris:

- After completing the cut, could you turn off the jigsaw and set it aside? Clear any plastic chips and debris from the work area to maintain visibility.

- Inspect and Sand (if necessary):

- Inspect the cut edge to ensure it meets your requirements. If there are any rough or uneven areas, you can use sandpaper to smooth them out.

Maintenance and Blade Care

Proper maintenance and blade care are essential to ensure your jigsaw blades’ longevity and optimal performance. After each use, cleaning your blades meticulously is crucial, removing sawdust, debris, and resin buildup from the teeth and body. Store them in a dry, clean environment to prevent corrosion, and consider using a dedicated blade storage case for organization and protection.

Before storing, apply a light machine oil or blade lubricant coating to prevent rust and corrosion. Regularly inspect your blades for signs of damage, wear, or dullness, and promptly replace damaged or worn blades. Sharpening is an option for some blades, like those designed for wood, but follow safety precautions and manufacturer guidelines. Proper blade installation, selection, and cooling techniques are vital for blade maintenance.

Also, maintain your jigsaw’s components, and always prioritize safety by wearing appropriate gear during blade care and maintenance. By following these steps, you can maximize the lifespan of your jigsaw blades and ensure safer and more efficient cutting operations for your woodworking and construction projects.

Safety Measures When Using a Jigsaw

Like any power tool, using a jigsaw requires severe adherence to safe and secure measures to forestall mishaps and injuries. Here are essential safety precautions to follow when using a jigsaw:

- Read the User Manual: Before operating your jigsaw, thoroughly read the user manual provided by the manufacturer. Familiarize yourself with the tool’s features, controls, and safety guidelines.

- Wear Appropriate Safety Gear:

- Safety Glasses or Goggles: Safeguard your eyes from debris, sawdust, and flying particles.

- Hearing Protection: Jigsaws can be noisy, so wear earplugs or earmuffs to prevent hearing damage.

- Dust Mask or Respirator: Use respiratory protection when using materials that generate dust or fumes.

- Work Gloves: Wear gloves to protect your hands and improve grip.

- Secure the Workpiece:

- If possible, clamp or secure the workpiece to a stable surface, such as a workbench or sawhorse. This prevents the material from moving during the cut.

- Choose the Right Blade:

- Select a jigsaw blade appropriate for the material and cut you intend to make. Using the wrong blade can lead to safety issues and poor results.

- Inspect the Blade:

- Before starting, ensure the blade is sharp and in good condition. Replace damaged or dull blades immediately.

- Disconnect Power:

- Always unplug the jigsaw from the power source when changing blades, adjusting settings, or performing maintenance.

- Secure Work Area:

- Maintain a clean, well-organized workspace. Remove clutter and keep the area well-lit to prevent tripping hazards and improve visibility.

- Follow Correct Body Position:

- Stand to the side of the jigsaw, not directly in line with the blade’s path. This reduces the risk of injury if the blade kicks back or breaks.

- Use Both Hands:

- Grip the jigsaw firmly with both hands, maintaining control of the tool throughout the cut.

- Start Slowly:

- When you start cutting, ease into the material slowly. Do not force the jigsaw through the material, which can lead to blade deflection and accidents.

- Keep Hands Clear:

- Ensure your hands and fingers are always clear of the blade’s path. Do not reach over or behind the cutting line while the jigsaw runs.

- Be Mindful of Cords:

- Keep the power cord and extension cords out of the cutting path to prevent accidental cuts and cord damage.

- Allow the Blade to Stop:

- After completing a cut, wait for the blade to come to a complete stop before setting the jigsaw down or attempting to remove the workpiece.

- Disconnect Power When Not in Use:

- When not actively using the jigsaw, unplug it or remove the battery if it’s cordless. This prevents accidental starts.

- Store Safely:

- Store your jigsaw in a secure location, out of the reach of children and away from moisture or extreme temperatures.

- Stay Focused:

- Maintain your concentration on the task at hand. Avoid distractions to ensure precise and safe cutting.

By following these safety measures, you can significantly lessen the gamble of mishaps while utilizing a jigsaw and enjoy safe and efficient woodworking or construction projects. Always prioritize safety and take the time to familiarize yourself with your jigsaw’s features and proper usage.

What Jigsaw Blade to Cut Plastic

Conclusion

Selecting the right jigsaw blade for cutting plastic is essential to achieve clean, precise, and efficient cuts. Plastic materials come in various forms and thicknesses, and choosing the appropriate blade type, tooth count, and design is crucial for a successful cutting experience.

By considering factors such as the type of plastic, the thickness of the material, and the desired cut quality, you can make an informed decision on the jigsaw blade that best suits your needs.

Continuously focus on well-being by wearing proper defensive stuff and following maker guidelines when using your jigsaw to ensure a smooth and accurate plastic-cutting process. With the right sharp edge and appropriate strategy, you can tackle plastic-cutting projects confidently and achieve the desired results.