Are you contemplating the ideal drill bit size for your #10 screws? Selecting the correct drill bit size is crucial for secure and efficient screw installation. In this guide, we’ll provide concise information on: what size drill bit for the #10 screw, ensuring that your projects proceed smoothly and securely. Let’s explore the details to answer the common question: What size drill bit for a #10 screw?

Screw Sizes and Labeling (#10):

Screw sizes are standardized for categorizing and identifying screws based on their dimensions and characteristics. Screws are typically labeled with a numerical size and sometimes additional information about their thread type or length. For instance, a standard screw size is #10.

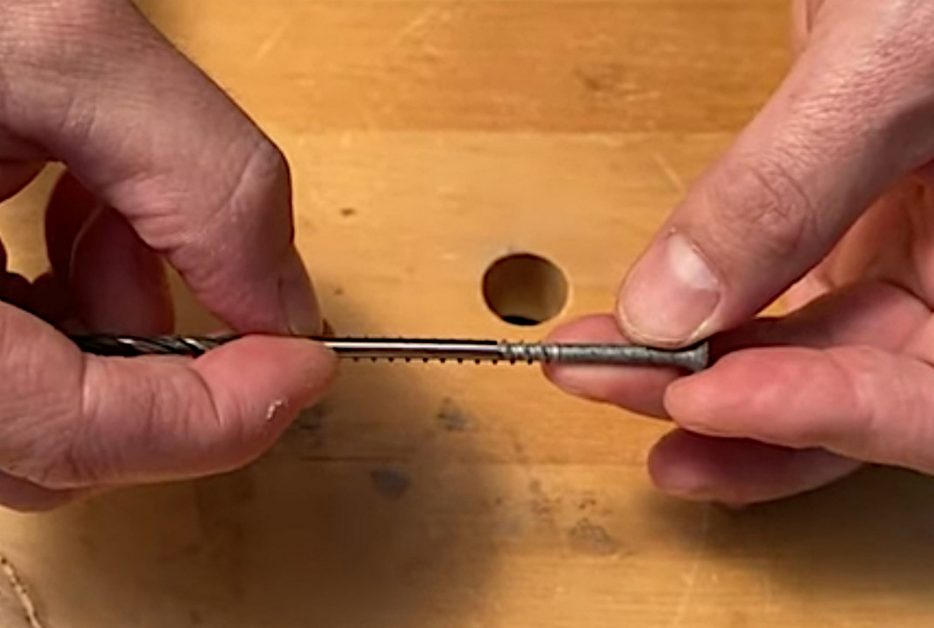

In this labeling, the number represents the screw’s size or significant diameter, which is the widest part of the screw’s threads, excluding the head. For a typical #10 screw, the primary diameter is approximately 0.190 inches or 4.83 millimeters.

The Relationship Between Screw Sizes and Drill Bit Sizes

The relationship between screw and drill bit sizes is crucial for secure and precise fastenings. When choosing a drill bit for a screw, it’s essential to select a bit size that matches or slightly exceeds the screw’s primary diameter. This ensures that the screw has enough material to grip and provides a secure fit.

For example, for a #10 screw with a primary diameter of approximately 0.190 inches, you would typically select a drill bit that matches this size or is slightly smaller, such as a 3/16-inch or 5mm drill bit, depending on your preferred measurement system (imperial or metric).

Various Sizing Systems Used for Screws (Imperial, Metric)

Screws are sized using different systems, primarily imperial (inch-based) and metric systems. Here’s a brief overview:

Imperial

In the United States and other countries using the imperial system, screw sizes are often labeled with numbers, fractions, or decimal inches. For example, #10-32 refers to a #10 screw with 32 threads per inch. Common imperial screw sizes include #6, #8, #10, 1/4-inch, and 3/8-inch.

Metric

In countries that follow the metric system, screws are labeled using millimeters for major diameters and thread pitches. For instance, an M6x1.0 screw has a primary diameter of 6 millimeters and a thread pitch of 1.0 millimeters. Standard metric screw sizes include M4, M5, M6, M8, and M10.

Importance of Choosing the Right Drill Bit Size

Selecting the correct drill bit size is paramount for ensuring the successful installation of screws. The drill bit size directly impacts the quality, strength, and reliability of the fastening process. Here’s why choosing the right drill bit size is crucial:

Optimal Thread Engagement

Using the correct drill bit size ensures that the screw threads bite securely into the material. This maximizes thread engagement, which is essential for a strong and durable connection. If the drill bit is too small, it may not allow for sufficient thread engagement, resulting in a weaker hold.

Preventing Splitting and Damage

Using the correct drill bit size in materials like wood or plastic helps prevent splitting or damage to the material. An oversized hole can weaken the material, while an undersized hole may cause it to crack or break during screw insertion.

Ease of Installation

An appropriately sized drill bit makes the installation process smoother and more efficient. It allows the screw to go in with less resistance and reduces the risk of damaging the screw or the workpiece. This is especially important when working with delicate materials.

Security and Stability

Correctly sized pilot holes and screws provide a secure and stable connection. This is vital for applications where safety and reliability are paramount, such as construction, woodworking, or automotive assembly.

Potential Problems and Risks Associated with Using the Wrong Size

Using the wrong drill bit size can lead to a range of problems and risks:

Insufficient Thread Engagement

When the hole is too large for the screw, there’s inadequate thread engagement. This results in a weak connection that can quickly come loose, jeopardizing the project’s structural integrity.

Difficulty Driving Screws

An oversized hole can make it challenging to drive the screw securely into the material. It may require excessive force, potentially damaging the screw head or stripping the threads.

Material Damage

Using an undersized drill bit can cause material damage, such as splitting wood, cracking plastic, or deforming metal. This not only weakens the material but also compromises the appearance of the finished project.

Screw Instability

A mismatched drill bit can lead to screw instability, causing the screw to wobble or sit unevenly. This instability can result in a weak connection.

Increased Risk of Stripping

Using the wrong drill bit size increases the risk of stripping the screws or the material’s threads. This makes future adjustments or disassembly difficult or impossible.

Basic Guidelines for Choosing the Right Drill Bit Size

A general rule of thumb for selecting the appropriate drill bit size for #10 screws and similar screw sizes is to choose a drill bit that matches the screw’s primary diameter or is slightly smaller.

The major diameter represents the widest part of the screw’s threads, excluding the head. This choice ensures a secure and snug fit, allowing the screw threads to grip the material properly.

Formula or Method for Calculating the Correct Drill Bit Size

To calculate the correct drill bit size for #10 screws or any screw with a known primary diameter, you can use the following formula:

Drill Bit Size = Major Diameter of Screw / Number of Threads Per Inch (TPI)

For #10 screws, which typically have a significant diameter of approximately 0.190 inches (4.83 millimeters) and commonly come with 24 or 32 threads per inch, you can calculate the drill bit size as follows:

- For 24 TPI: Drill Bit Size = 0.190 inches / 24 = 0.0079 inches per thread. This is approximately equivalent to 5/32 inches or 4 millimeters.

- For 32 TPI: Drill Bit Size = 0.190 inches / 32 = 0.0059 inches per thread. This is approximately equivalent to 3/16 inches or 4.8 millimeters.

These calculations provide suitable drill bit sizes for #10 screws based on the number of threads per inch. Choose the drill bit size that aligns with your specific needs and materials.

Resources or Charts to Find the Right Size

There are various resources and charts available to help users find the right drill bit size for #10 screws and other screw sizes:

- Drill Bit Size Charts: Numerous online resources and printed charts provide comprehensive lists of drill bit sizes for various screw sizes. These charts often include imperial and metric measurements and are organized by screw size and material type.

- Manufacturer Recommendations: Screw manufacturers often provide guidelines and recommendations for drill bit sizes to be used with their screws. Check the manufacturer’s product information or website for this guidance.

- Mobile Apps: Some mobile apps are designed to assist users in determining the correct drill bit size for specific screw sizes. These apps may include calculators and reference charts.

- DIY and Woodworking Guides: DIY and woodworking guides and books frequently offer sizing recommendations for various fastening tasks. These guides can be valuable references for selecting the right drill bit size.

Using these resources and the formula mentioned earlier, you can confidently determine the correct drill bit size for #10 screws and achieve secure and reliable fastenings in your projects.

Tips for Proper Drilling with the Chosen Drill Bit

When using the chosen drill bit effectively, begin by securing your workpiece firmly through clamping or proper support to prevent any unintended movement during drilling.

For materials like wood, consider creating pilot holes with a minor drill bit before using the final-sized one for the screw; this prevents splitting and ensures accurate screw placement.

Adjust the drill’s speed according to the material you’re working with—higher rates for softer materials like wood and plastic and slower speeds for more complex materials like metal or masonry.

Always maintain a perpendicular (90-degree) angle between the drill bit and the workpiece to drill straight holes, as deviation can result in skewed or uneven spots. Apply consistent and moderate pressure while preparing, avoiding excessive force that may cause binding or overheating.

Additionally, consider using cutting oil or a suitable lubricant when drilling metal to reduce friction and overheating while extending the drill bit’s lifespan. Lastly, remember to periodically retract the drill bit to clear away chips or debris, ensuring smooth and efficient drilling.

Drilling Techniques and Safety Precautions

Prioritize safety when drilling by wearing appropriate gear, including safety glasses or goggles to shield your eyes from debris and hearing protection if working in a noisy environment. When dealing with materials producing dust or fumes, utilize a dust mask or respirator to protect your respiratory system. Maintain a well-organized, well-lit work area to minimize tripping hazards and ensure clear visibility.

Follow the manufacturer’s instructions for your specific drill, following recommended speeds, maintenance procedures, and safety precautions. Abstain from wearing accessible attire or adornments that could be found in the training, and permanently remove any potential safety hazards.

Manage the power cord properly to prevent tripping and potential damage, particularly with corded drills. Unplug the exercise from the power source when changing drill bits or making adjustments to avoid accidental activation.

Secure the workpiece thoroughly through clamping or securing it to prevent spinning or shifting during drilling. Keep your hands and body clear of the drill bit’s path to avoid accidental contact and injury. Be familiar with the drill’s emergency stop mechanism, which is readily accessible in case of unforeseen issues. These drilling techniques and safety precautions ensure the effective use of your chosen drill bit and make a more secure and proficient workspace for your tasks.

Different Types of Drill Bits for Various Materials

Twist Drill Bits

Twist drill bits are the most common and versatile. They have spiral grooves that aid in chip removal and come in various materials and coatings for drilling wood, metal, and plastic.

Brad Point Bits

Brad-point bits are designed for drilling precise and clean holes in wood. They have a pointed tip that helps prevent wandering, making them ideal for woodworking tasks.

Spade Bits (Flat Wood Bits)

Spade bits have a level, paddle-like shape with a sharp tip. They excel at drilling large holes in wood and are often used in construction and carpentry.

Forstner Bits

Forstner bits are specialized for drilling flat-bottomed holes with clean edges in wood. They are commonly used for hinge and dowel hole drilling.

Masonry Bits

Masonry bits have carbide or tungsten tips for drilling into concrete, brick, or stone. They come in various styles, including hammer bits for rotary hammer drills.

HSS (High-Speed Steel) Bits

HSS bits are suitable for drilling metal, including steel, aluminum, and brass. They can withstand high-speed drilling and are often coated with materials like titanium nitride (TiN) for extended durability.

Cobalt Bits

Cobalt drill bits are excellent for drilling hard metals like stainless steel. They are known for their heat resistance and durability.

Step Bits

Step bits have multiple stepped diameters and are commonly used for drilling holes of varying sizes in metal and plastic. They are often used in electrical and plumbing applications.

Choosing the Best Drill Bit for #10 Screws

The choice of drill bit for #10 screws depends on the material you are drilling into:

- Wood: Brad Point bits or standard Twist bits work well for wood applications. Brad Point bits provide excellent precision and clean holes, making them a top choice for woodworking projects using #10 screws.

- Metal: High-speed steel (HSS) or Cobalt bits are recommended when drilling into metal. HSS bits are suitable for softer metals, while Cobalt bits are better for hard metals like stainless steel. Ensure you use cutting oil or lubricant to reduce heat and friction when drilling metal.

- Masonry: For masonry or concrete, specialized masonry bits are essential. These bits are designed to withstand the hardness of these materials and should be used with a hammer drill for the best results.

- Plastic: Standard Twist bits or Brad Point bits can work well for drilling into plastic. Use a slow drill speed to prevent plastic from melting or deforming.

Common Problems During Drilling with #10 Screws

Splitting Wood

When drilling into wood, especially near the edge or end grain, splitting can occur due to the force exerted by the screw. This can weaken the material and compromise the fastening.

Overheating and Dulling of Drill Bit

Drilling too fast or without proper lubrication, especially in metal, can cause the drill bit to overheat and dull quickly. A dull bit can lead to poor hole quality and increased effort.

Wandering or Off-Center Holes

Drilling off-center or having the drill bit wander from the intended location can result in misaligned holes, making it difficult to properly secure the #10 screw.

Difficulty in Hard Materials

Drilling into hard materials like metal or masonry can be challenging without the proper technique and tools. It may lead to slow progress or even damaged drill bits.

Solutions and Tips to Overcome Common Drilling Issues

Preventing Wood Splitting

- Use Pilot Holes: Create pilot holes slightly smaller than the screw’s primary diameter to reduce the risk of splitting in wood.

- Countersink Holes: For wood, consider using countersink bits to create recesses for screw heads, preventing surface splitting and ensuring a flush finish.

Overheating and Dulling of Drill Bit

- Lubrication: When drilling metal, use cutting oil or a lubricant to reduce heat and friction. Apply it periodically during drilling.

- Proper Speed: Adjust the drill to the appropriate speed for the material. Slower speeds work better for hard materials, while faster speeds suit softer ones.

- Quality Drill Bits: Invest in high-quality drill bits for the specific material you’re working with. Sharp bits last longer and drill more effectively.

Wandering or Off-Center Holes

- Center Punch: Before drilling, use a center punch to create a slight indentation where you want to drill. This helps guide the drill bit and prevents wandering.

- Clamping and Guide Blocks: Use clamps and blocks to secure the workpiece and guide the drill bit along a straight path.

Difficulty in Hard Materials

- Select the Right Bit: Ensure you use the appropriate drill bit type for the material. For hard metals or masonry, use specialized bits designed for those materials.

- Use a Hammer Drill: If drilling into concrete or masonry, use a hammer drill mode to provide additional impact force.

By implementing these solutions and tips, you can effectively address and overcome common issues when drilling with #10 screws. This will result in cleaner, more precise holes and a smoother overall drilling experience.

Common Challenges When Choosing the Correct Size

Choosing the correct size, whether it’s for drill bits, screws, or other fasteners, can indeed present several common challenges for individuals:

- Lack of Knowledge: Many people may need a deeper understanding of sizing standards or may be unfamiliar with how to interpret sizing labels, making it challenging to select the correct size.

- Variety of Standards: Different materials and applications often require adherence to specific sizing standards, such as imperial or metric. Navigating these standards can confuse those who need to become more familiar with them.

- Material Variations: The type of material being worked with can significantly impact the choice of size. For instance, wood, metal, and masonry may require different sizing considerations.

- Precision Requirements: Some projects demand high precision, where even a slight deviation in size can lead to problems. Determining the correct size becomes critical in such cases.

- Availability of Tools and Resources: Access to the right tools, such as drill bit size charts or measuring instruments, may be limited for some individuals, making it challenging to verify sizes accurately.

- Subjectivity: What one person considers the “correct” size may differ from another’s interpretation, leading to confusion and potential errors in selection.

- Project Complexity: Complex projects involving multiple components or materials may require a deep understanding of sizing standards and careful consideration of various factors, which can be overwhelming for some.

To address these challenges, individuals should seek educational resources, consult sizing charts and guides, and consider seeking advice from experts or professionals when selecting sizes for specific applications.

Conclusion

Determining the right size drill bit for a #10 screw is a crucial step in ensuring the success of your project. By matching the drill bit diameter to the screw size, you can create pilot holes that allow for easy and secure screw installation.

The suggested drill bit size for a #10 screw is typically 3/16 inch (4.76 millimeters), but it’s essential to double-check the manufacturer’s recommendations or test on a scrap piece of material to achieve the best results. Using the correct drill bit size ensures a tighter fit and reduces the risk of splitting or damaging the material you’re working with.