Are you curious about the price range of table saws? This article will delve into “How much does a Table Saw Cost?” and provide the necessary information to make an informed decision. Additionally, we will address another important aspect of table saws: “How thick is a Table Saw Blade?”

Different Types of Saws’ Price Ranges & Features

Stationary Table Saws: Features and Average Prices

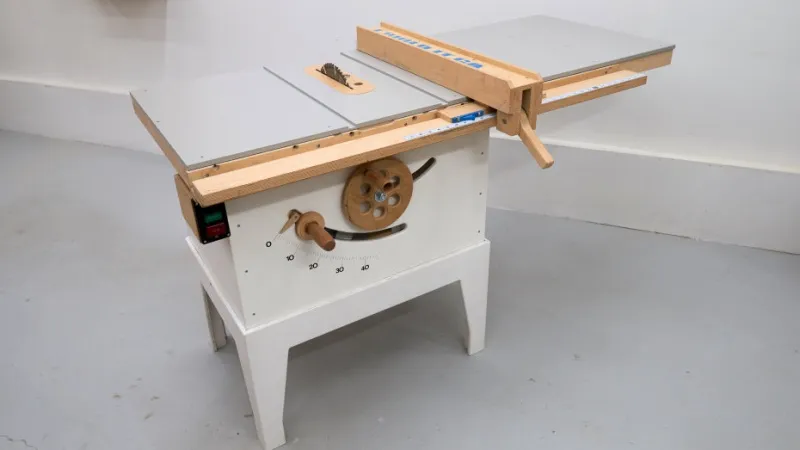

Stationary table saws are a type of woodworking tool designed to stay in one place, providing stability and accuracy for various cutting tasks. They are commonly used in workshops or construction sites requiring a reliable and sturdy cutting tool. This step will explore stationary table saws and explain their features and average prices.

Stationary table saws are known for their sturdy construction and powerful motors, making them suitable for handling large and heavy materials. These saws have a flat tabletop surface with an adjustable cutting blade that extends through the surface. You can adjust the blade’s height and angle to achieve different cutting depths and angles.

One of the main advantages of stationary table saws is their precision and stability. Since these saws remain fixed in one position, they provide a solid base for accurate cutting. This stability ensures that the workpiece stays steady during cutting, resulting in clean and precise cuts. Stationary table saws are particularly useful for tasks that require straight cuts or ripping large boards.

Pricing

Regarding pricing, stationary table saws vary widely depending on features, brand, and quality. On average, entry-level stationary table saws are priced between $300 and $500. These models typically offer basic functionality and may have limited features.

Mid-range stationary table saws, priced between $500 and $1,000, offer additional features and improved build quality. They suit woodworking enthusiasts and professionals who require more advanced capabilities and durability.

For those seeking high-end stationary table saws with advanced features like digital displays, precision fences, and powerful motors, prices can range from $1,000 to $3,000 or more. These models are designed for professional use and can handle heavy-duty cutting tasks.

When choosing a stationary table saw, you must consider your specific needs and budget. While higher-priced models may offer additional features and durability, ensuring that the saw you choose aligns with the projects you’ll be working on is crucial.

Cabinet Table Saws: Power, Precision, and Price Points

Cabinet table saws are an advanced woodworking tool known for their exceptional power, durability, and precision. In this step, we will explore cabinet table saws and explain their features and average prices.

Cabinet table saws are designed with a fully enclosed cabinet-style base, which offers excellent stability and helps minimize vibrations during cutting.

These saws are typically heavier and sturdier than other table saw types, making them the preferred choice for professional woodworkers and serious enthusiasts requiring high-performance tools.

One of the standout features of cabinet table saws is their powerful motors. These saws have high-horsepower motors, usually ranging from 3 to 5 horsepower or more.

The robust motor enables cabinet table saws to cut through thick and dense materials, such as hardwoods, making them ideal for demanding woodworking projects.

Precision

Precision is a key characteristic of cabinet table saws. They often come with advanced features like precision fences and miter gauges, allowing accurate and repeatable cuts. The solid construction and precise adjustments of cabinet table saws ensure consistent results, even when working on intricate woodworking tasks.

Due to their professional-grade quality and features, cabinet table saws generally have higher price points than other table saws. On average, entry-level cabinet table saws are priced between $1,000 and $2,000. These models offer reliable performance and essential features for woodworking enthusiasts willing to invest in a high-quality saw.

Mid-range cabinet table saws, offering additional features and enhanced durability, typically range from $2,000 to $3,500. Professional woodworkers often favor these saws requiring precise cuts and long-lasting performance for their daily woodworking operations.

For top-of-the-line cabinet table saws with advanced features like digital controls, premium fences, and exceptional build quality, prices can exceed $3,500. These high-end models are designed for heavy-duty industrial use and woodworking professionals who demand maximum performance and reliability from their tools.

When considering a cabinet table saw, evaluating your woodworking needs, budget, and skill level is important. Investing in a cabinet table saw can significantly enhance your woodworking capabilities, allowing you to tackle complex projects precisely and easily.

Hybrid Table Saws: Power and Portability at a Mid-Range Price

Hybrid table saws are a versatile type of woodworking tool that combines the best features of cabinet and contractor table saws. In this step, we will explore hybrid table saws and explain their features and average prices.

Hybrid table saws are designed to bridge the gap between professional-grade cabinet table saws and the more portable contractor table saws. They balance power, functionality, and affordability, making them suitable for serious woodworking enthusiasts and small-scale professional workshops.

Size & Portability

One of the distinguishing features of hybrid table saws is their compact size and portability. They are larger and heavier than contractor table saws but still more manageable and mobile than cabinet table saws. This makes them convenient for woodworkers who need to move their saws between job sites or work in limited workshop spaces.

Hybrid table saws often feature a sturdy and open-stand design, providing stability during cutting while allowing for easier access to maintenance and adjustments. They typically come with a powerful motor ranging from 1.5 to 2 horsepower, which enables them to handle a wide range of woodworking tasks, including cutting through hardwoods with relative ease.

Another notable feature of hybrid table saws is their improved dust collection systems. They are equipped with built-in dust ports and efficient dust collection mechanisms, helping to keep the workspace cleaner and reduce airborne particles. This contributes to a healthier and safer working environment.

Regarding pricing, hybrid table saws generally fall in the mid-range category. On average, entry-level hybrid table saws are priced between $800 and $1,500. These models offer reliable performance, essential features, and good value for woodworking enthusiasts looking to upgrade from contractor table saws without the higher cost of cabinet table saws.

Mid-range hybrid table saws, which provide enhanced features like improved fences and more powerful motors, typically range from $1,500 to $2,500. Woodworking enthusiasts and small professional workshops often favor these models that require higher precision and durability.

Hybrid table saws offer a balanced combination of power, functionality, and affordability. They are popular for woodworking enthusiasts and small professional workshops seeking a versatile and reliable tool for various cutting tasks.

Portable Table Saws

Portable table saws are convenient and compact woodworking tool that offers flexibility and mobility for various projects. In this step, we will explore portable table saws and explain their features and average prices.

They are an excellent choice for carpenters, contractors, and DIY enthusiasts who require a saw that can be easily moved between job sites or used in smaller workshop spaces.

One of the key features of portable table saws is their compact size. They are designed to save space, allowing for convenient storage and transportation. Despite their smaller dimensions, portable table saws offer essential cutting capabilities and functionality.

These saws often come with folding stands or compact bases that make them easy to set up and dismantle. This enables quick and hassle-free assembly on job sites or tight workshop areas. Some portable table saws also feature built-in handles or wheels, enhancing mobility.

Regarding power, portable table saws typically have motors with lower horsepower than larger stationary models. However, they can still handle common woodworking tasks, such as cutting plywood, boards, and smaller materials. The motors usually range from 1 to 2 horsepower, providing sufficient power for portable cutting needs.

Regarding pricing, portable table saws offer a range of options to fit different budgets. Entry-level portable table saws generally range from $200 to $400. These models provide basic functionality and are suitable for DIY enthusiasts and occasional woodworking projects.

Mid-range portable table saws, priced between $400 and $800, often have improved features such as better fences and enhanced cutting capacity. They cater to contractors and professionals who require more versatility and durability for their on-site woodworking tasks.

High-end portable table saws, priced above $800, offer advanced features like precise miter gauges, superior dust collection systems, and larger cutting capacities. These top-tier models are designed for professionals who demand exceptional performance and accuracy while working in diverse environments.

When selecting a portable table saw, it’s important to consider your specific needs, portability requirements, and budget. Portable table saws provide convenience and flexibility, even though they may have some power and cutting capacity limitations compared to larger saws.

Key Factors Influencing Table Saw Pricing: Type, Model, and Features

Table saws are available in various types and models, and these factors significantly impact their prices. The type and model of a table saw refer to its specific design, features, and functionalities. Let’s explore how these factors affect the pricing of table saws.

Three types of table saws

Contractor Table Saws

Contractor table saws are designed for portability and are commonly used in job sites or small woodworking shops.

Cabinet Table Saws

Cabinet table saws are heavy-duty machines primarily aimed at professional woodworkers and dedicated enthusiasts. These saws feature a robust, enclosed cabinet-style base that enhances stability and reduces vibrations during operation.

Cabinet saws typically have powerful induction motors, larger table surfaces, and superior dust collection systems. The advanced features and solid build quality of cabinet table saws contribute to their higher price range.

Hybrid Table Saws

Hybrid table saws combine the best elements of contractor and cabinet saws, making them suitable for intermediate-level woodworkers. These saws often feature an enclosed base similar to cabinet saws but with lighter construction and a smaller motor.

Hybrid table saws strike a balance between portability and power. They are generally priced between contractor and cabinet saws, reflecting their intermediate features and capabilities.

Different manufacturers offer various models within each type of table saw. Each model may introduce unique features such as adjustable fences, advanced safety systems, improved dust collection mechanisms, and enhanced cutting capacities.

These additional features and innovations can contribute to a higher price point for a particular model.

Contractor table saws are more affordable due to their portable design and simpler features. Hybrid table saws compromise portability and power at a mid-range price. Additionally, the specific table saw model, with its distinct features and advancements, can influence its pricing.

Exploring Table Saw Features and Their Influence on Pricing

The features available in a table saw can significantly affect its price. Table saws have various features that enhance functionality, safety, and convenience.

Motor Power

The motor power of a table saw determines its cutting performance and capacity. Table saws with higher motor power can handle tougher materials and make more precise cuts.

Generally, table saws with more powerful motors are more expensive than those with lower power ratings. Higher motor power will likely come at a higher price if you require a table saw for heavy-duty tasks or professional use.

Blade Size and Type

The size and type of blade used in a table saw determine its cutting capacity and versatility. Table saws can accommodate different blade sizes, typically 8 to 12 inches in diameter.

Larger blades allow for deeper cuts and increased ripping capacity. Specialized blade types, such as dado or thin-kerf blades, can expand the saw’s capabilities.

Fence System

The fence system plays a crucial role in ensuring accurate and consistent cuts. A high-quality fence system allows for precise adjustments and reliable parallel alignment to the blade.

Some table saws offer advanced fence systems with features like rack-and-pinion mechanisms or digital readouts for enhanced accuracy. These improved fence systems contribute to higher prices, providing better control and precision during cutting operations.

Safety Features

Many table saws include safety features to protect the user from accidents. These features may include blade guards, riving knives, anti-kickback pawls, and emergency stop switches.

Dust Collection System

Efficient dust collection is crucial for maintaining a clean and safe working environment. Table saws with effective dust collection systems help minimize airborne dust particles and clean the workspace.

Some models have built-in dust ports or collection bags, while others may offer compatibility with external dust extraction systems.

Additional Features

Table saws may also have additional features that enhance usability and convenience. These can include miter gauges for angled cuts, onboard storage for accessories, extendable work surfaces, mobile bases for portability, and even built-in measurement systems.

Including these extra features can increase the price, as they provide added value and convenience for the user.

The features available in a table saw directly impact its price. Factors such as motor power, blade size and type, fence system quality, safety features, dust collection efficiency, and additional conveniences all contribute to the overall cost of the table saw.

Saw Ripping Capacity: Impact on Table Saw Pricing

Ripping capacity refers to the maximum width of material that a table saw can cut in a single pass. Understanding the significance of ripping capacity and its impact on pricing can help you choose the right table saw for your woodworking needs. Let’s explore this factor in more detail.

Definition of Ripping Capacity

Ripping involves cutting a workpiece lengthwise along its grain. The ripping capacity of a table saw indicates the maximum distance between the blade and the rip fence, determining the width of material that can be cut. For example, if a table saw has a ripping capacity of 24 inches, it can cut a workpiece up to 24 inches in width.

Importance of Ripping Capacity

Ripping capacity is crucial because it determines the size of workpieces that can be handled. If you frequently work with larger materials, such as wide boards or plywood sheets, you would require a table saw with a greater ripping capacity.

Impact on Pricing

Table saws with larger ripping capacities generally have higher price points than smaller ones. This is because achieving a larger ripping capacity requires a sturdier and more precise construction.

The table surface, rip fence, and blade alignment mechanisms must be designed to accommodate wider workpieces. Consequently, the increased materials and engineering in achieving a larger ripping capacity contribute to a higher price.

Considerations for Ripping Capacity

When selecting a table saw based on its ripping capacity, it’s important to consider the types of projects you regularly undertake.

However, if you primarily work with narrower materials, opting for a table saw with a smaller ripping capacity can help save costs without compromising functionality.

It’s worth noting that some table saws offer expandable rip fences or extension wings that can increase the effective ripping capacity.

These features allow you to handle larger workpieces while maintaining the flexibility to work with narrower materials. Remember that such additional features may also contribute to a higher price.

The ripping capacity of a table saw significantly influences its price. Table saws with larger ripping capacities are generally priced higher due to the increased materials and engineering required.

Evaluating your specific woodworking needs and considering the width of materials you typically work with will assist you in selecting a table saw with an appropriate ripping capacity while considering the price range.

Bevel Cuts Capability: Influence on Table Saw Pricing

Bevel cuts refer to angled cuts on a workpiece other than the standard 90-degree vertical cut. Understanding the significance of bevel cuts capability and its impact on pricing can help you decide when selecting a table saw. Let’s explore this factor in more detail.

Definition of Bevel Cuts Capability

Bevel cuts capability refers to a table saw’s ability to tilt the blade at an angle other than 90 degrees, allowing for angled cuts on workpieces.

A table saw with good bevel cuts capability enables you to make precise bevel cuts, such as miter or compound cuts, which are essential for various woodworking projects.

Importance of Bevel Cuts Capability

Bevel cut’s capability expands the versatility of a table saw. It allows you to create beveled edges, angled joints, or decorative elements in your woodworking projects.

Whether you need to cut trim pieces, create angled joints for furniture, or add intricate designs to your work, the ability to make precise bevel cuts is essential. Therefore, a table saw with reliable and accurate bevel cuts capability is valuable for many woodworkers.

Impact on Pricing

The bevel cuts capability of a table saw can influence its price. Table saws that offer a wide range of bevel angles and precise adjustments tend to be more expensive than those with limited or less precise bevel cuts capability.

A higher price may include advanced mechanisms, such as a robust tilting mechanism, precise angle indicators, and easy-to-use controls, which enhance the accuracy and convenience of making bevel cuts.

Considerations for Bevel Cuts Capability

When considering the bevel cuts capability of a table saw, it’s important to assess your specific woodworking needs. Determine the range of bevel angles you anticipate using in your projects.

If you frequently work with complex angles or require precise bevel cuts, investing in a table saw with advanced bevel cuts capability may be worth the higher price.

However, if your projects primarily involve straight cuts or basic angles, a table saw with a more modest bevel cuts capability might suffice and help you save on costs.

It’s worth noting that some table saws offer additional features to enhance bevel cuts capability, such as adjustable bevel stops, positive bevel angle locks, or even sliding or tilting tables for improved maneuverability.

These features may contribute to an increase in price but can also provide added convenience and accuracy when working with bevel cuts.

Table saws with advanced and precise bevel cuts capability generally come at a higher price due to the inclusion of specialized mechanisms and features.

Assessing your woodworking needs and considering the range of bevel angles you require will help you select a table saw with an appropriate bevel-cut capability while considering the associated price range.