If you are thinking about what is a band saw. A band saw is a fundamental tool with diverse applications in woodworking, metalworking, and other industries. It comprises a continuous, toothed metal band that rotates around multiple wheels, enabling precise and efficient cutting of various materials.

A band saw represents a powerful tool that operates by utilizing a continuous looped band equipped with teeth along its edge. This band, commonly referred to as a blade, is stretched over two or more rotating wheels, with one wheel being driven by an electric motor. The band continuously moves as the motor spins the wheels, generating a cutting motion.

The design of a band saw encompasses several advantages over alternative saw types. The uninterrupted loop of the blade facilitates smooth and consistent cutting, making it particularly well-suited for shaping curved or irregular objects. Moreover, the thin and narrow blade minimizes material wastage by creating a thin kerf, or cut, during the cutting process.

The Significance and Versatility of Band Saws

Band saws are pivotal in various industries thanks to their great importance and exceptional versatility. These cutting-edge machines have revolutionized how we handle woodworking, metalworking, and other intricate cutting tasks. This note aims to shed light on the indispensability of band saws and their wide range of applications.

Importance of Band Saws

Precision Cutting

Band saws are renowned for their ability to achieve precise and intricate cuts. Their slender, continuous loop blade with evenly distributed teeth ensures smooth, clean, and accurate cuts, enabling artisans to achieve the desired shapes and angles with minimal effort. This precision is crucial in woodworking, metal fabrication, and even in the production of musical instruments.

Flexibility and Adaptability

Band saws come with adjustable blades, which can be easily swapped to accommodate different materials, thicknesses, and cutting requirements.

This flexibility allows professionals to tackle various projects, from simple curves and straight cuts to complex patterns and irregular shapes. Whether cutting wood, metal, plastic, or other materials, band saws can easily handle diverse tasks.

Resawing Capabilities

One of the standout features of band saws is their ability to perform resawing, which involves splitting a thick piece of wood into thinner sections.

This process is particularly useful in woodworking, allowing artisans to maximize the yield from expensive and rare wood stock. Using a band saw for resawing; materials can be efficiently utilized, reducing waste and maximizing cost-effectiveness.

The versatility of Band Saws

Woodworking Applications

Band saws excel in woodworking tasks such as ripping lumber, cutting intricate shapes, creating smooth curves, and crafting joinery components. They are essential for furniture making, cabinetry, carpentry, and crafting decorative woodwork. Additionally, they are ideal for cutting veneers, laminates, and thin strips of wood.

Metalworking Applications

Band saws are widely used in metal fabrication and manufacturing processes. They can effortlessly cut through various metals, including steel, aluminum, and brass, allowing for the production of precise parts and components. Band saws are commonly employed in machine shops, metalworking industries, and automotive workshops.

Other Applications

Beyond woodworking and metalworking, band saws find applications in diverse fields. They are valuable tools in butcheries for cutting meat, construction sites for cutting plastic or PVC pipes, and even in the entertainment industry for sculpting foam, creating props, and crafting set designs.

Components of a Band Saw

A band saw is a versatile and widely used power tool in the woodworking and metalworking industries. Understanding a band saw’s key features is crucial for beginners and experienced users.

Frame and Base

The frame and base form the foundation of a band saw. They provide stability and support to the entire machine. Typically made of heavy-duty cast iron or steel, the frame, and base ensure rigidity and minimize vibrations during operation, contributing to accurate and smooth cuts.

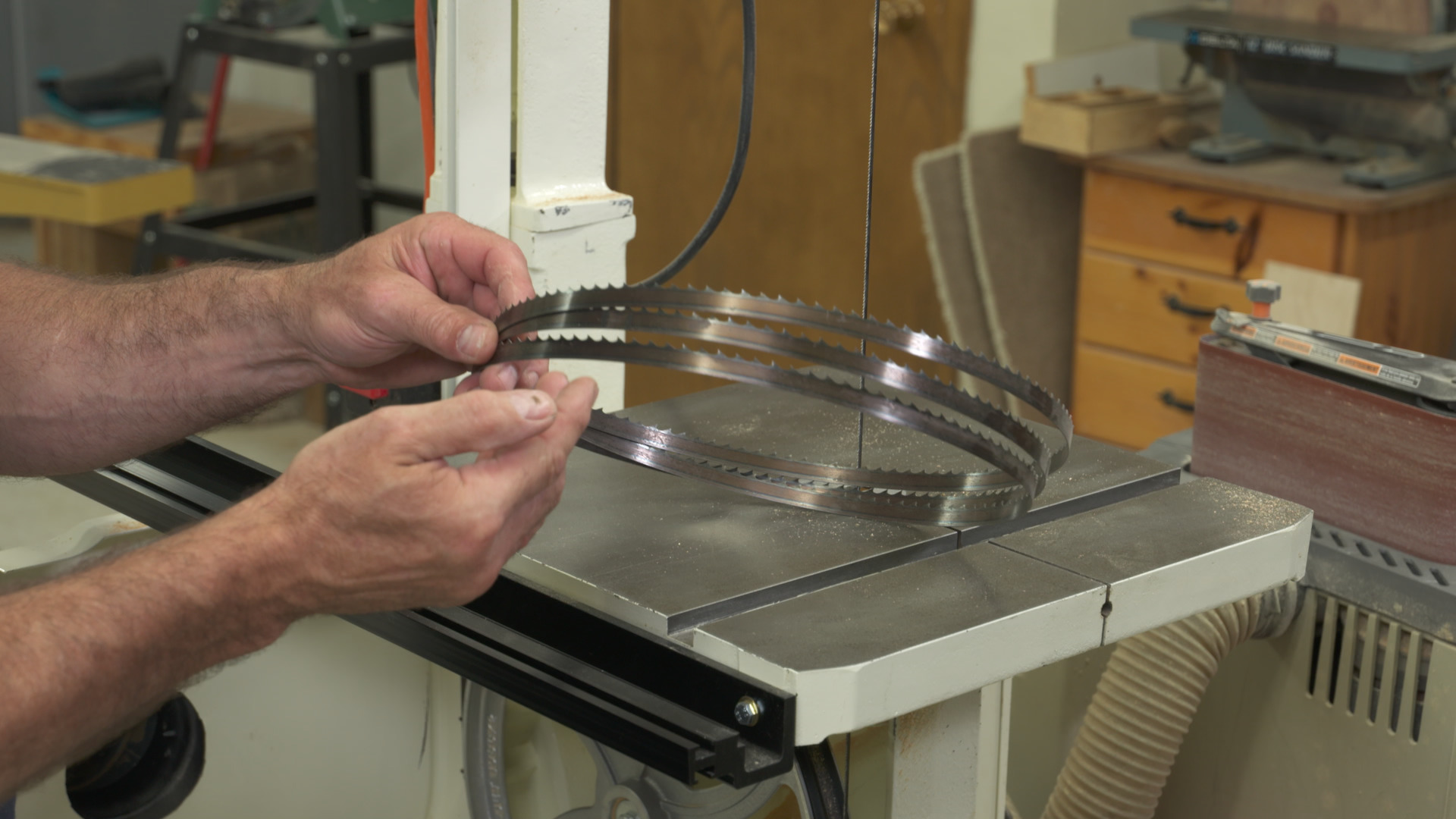

Blade

The blade is a crucial component of a band saw and determines the type of cuts it can make. The blade’s teeth vary in size, pitch, and configuration based on the cut material. Choosing the appropriate blade for the desired cutting task is essential to achieve optimal results.

Wheels

Band saws typically have two wheels, an upper wheel and a lower wheel, which are responsible for driving the blade. These wheels are usually made of cast iron or aluminum alloy.

The upper wheel is adjustable and guides the blade, while the lower wheel provides power and tension to keep the blade taut. The wheels’ diameter affects the cutting capacity and determines the minimum radius of the curves that can be cut.

Table

The table is the flat surface where the workpiece rests during cutting. It is adjustable and can be tilted to accommodate various cutting angles. The band saw tables may have a miter gauge or a fence to make accurate straight or angled cuts. Some band saws also feature a rip fence for resawing thicker materials.

Guides and Bearings

Band saws incorporate guides and bearings to align the blade and minimize deflection. The blade guides, usually located above and below the table, prevent lateral movement of the blade during cutting. They can be adjustable to ensure proper blade tracking. Bearings support the blade and reduce friction, allowing smooth and efficient operation.

Motor and Drive System

The motor and drive system provide the power to operate the band saw. Band saws can have various motor configurations, including direct or belt-driven motors. The motor’s power and speed determine the cutting capacity and the types of materials that can be cut.

How Band Saw Works

Band saws are highly versatile power tools that utilize a continuous metal blade with teeth to cut various materials. This note provides a concise overview of the operating principles behind band saws, shedding light on their mechanism and operation.

Structure of a Band Saw

Band saws consist of several key components:

- a) Blade: A long, continuous metal band with evenly spaced teeth that perform the cutting action.

- b) Wheels: Two large wheels, typically metal or rubber, drive the blade and maintain its tension.

- c) Table: A flat surface positioned beneath the blade supports the material being cut.

- d) Guides: Bearings or blocks that align the blade and ensure accurate cutting.

- e) Motor: The power source that drives the wheels and powers the cutting process.

Blade Tension and Tracking

Proper blade tension is crucial for achieving precise cuts. The tension is adjusted by a mechanism that controls the position of the upper wheel, maintaining the desired pressure on the blade.

Additionally, the tracking mechanism ensures the blade stays aligned on the reels, reducing friction and preventing premature wear.

Cutting process

When the band saw is turned on, the motor powers the rotation of the wheels. The teeth on the blade come into contact with the material to be cut, creating a continuous cutting motion.

As the material is guided along the table, the blade’s teeth remove thin slices, resulting in a clean and accurate cut.

Variable Speed and Cutting Angles

Band saws often feature adjustable speed settings, allowing operators to adapt to different materials and cutting requirements.

The speed can be modified using a control panel, enabling the blade to operate at the optimal velocity for the specific task at hand. Additionally, the band saws table can be tilted to cut at various angles, expanding the tool’s versatility.

Safety Measures

Band saws incorporate safety features to protect the operator. These may include blade guards to shield against accidental contact, emergency stop buttons, and mechanisms to prevent the blade from operating when the blade guard is not in place. Operators are advised to wear appropriate safety gear, such as goggles and gloves, while using a bandsaw.

Types of Band Saws

Band saws are versatile cutting tools used in various industries, including woodworking, metalworking, and meat processing. They offer precision cutting, curved or straight, through a continuous band of toothed metal. This brief note provides an overview of the different types of band saws commonly available in the market.

Vertical Band Saw

A vertical band saw is the most common type primarily used for woodworking. It features a vertically positioned blade that moves up and down. This design allows for intricate cuts, making it ideal for cutting curves and irregular shapes.

Horizontal Band Saw

The horizontal band saw is designed for cutting long, straight materials such as metal bars or pipes. It features a blade that moves horizontally, allowing for efficient and accurate straight-line cutting.

Horizontal band saws often have adjustable cutting angles, making them suitable for miter cuts and bevel cuts. These saws are commonly used in metalworking shops, fabrication plants, and construction sites.

Portable Band Saw

As the name suggests, portable band saws are lightweight and compact, designed for on-site cutting tasks. They are battery-powered or corded, allowing for greater mobility.

Electricians, plumbers, and HVAC technicians commonly use portable band saws for cutting metal, plastic, and other materials in tight spaces. They offer the convenience of a band saw in a portable form factor.

Meat Band Saw

Meat band saws are specialized tools used in the food industry, particularly for meat processing. Meat band saws often feature safety guards and sanitation features to ensure hygiene standards are met. These saws are commonly found in butcher shops, meatpacking plants, and commercial kitchens.

Double Column Band Saw

Double-column band saws are heavy-duty machines used for cutting large and thick materials. They feature a robust frame with two columns that provide stability and support for cutting heavy workpieces. These band saws are capable of handling demanding tasks in industries such as aerospace, automotive, and metal fabrication.

Applications of Band Saw

Band saws are versatile tools with various applications across various industries. These cutting-edge machines use a continuous band of toothed metal to effortlessly slice through different materials, making them invaluable assets in small-scale workshops and large-scale production facilities.

The woodworking industry benefits significantly from the precision and ability of band saws to cut intricate shapes. With their exceptional curve-cutting capabilities, these saws are perfect for crafting furniture, cabinets, and musical instruments. Woodworkers can rely on band saws to create intricate designs while minimizing material waste due to the accuracy of their cuts.

Band saws are crucial in cutting metal stock, tubes, and pipes in the metalworking industry. Their clean and accurate cuts ensure precise measurements, reducing the need for additional finishing processes.

These saws are highly efficient when working with metals like steel, aluminum, and brass, making them indispensable in fabrication shops and metalworking factories.

Band saws also find extensive use in the automotive industry. They are essential for cutting metal bars, tubes, and pipes used in the manufacturing of chassis components, exhaust systems, and roll cages.

With the ability to cut at different angles and handle heavy-duty materials, band saws are invaluable tools in automotive repair shops and production lines.

In construction and carpentry, band saws are employed for cutting beams, rafters, and other large pieces of lumber. They also provide accurate and precise cuts in materials such as plywood and particleboard, making them ideal for constructing doors, windows, and frames.

Band saws have even gained popularity among craftspeople and hobbyists due to their versatility. These saws can cut various materials, including plastics, acrylics, and foam. Hobbyists can use band saws to create intricate designs for model making, toy crafting, and other artistic endeavors.

Safety Consideration

This article provides valuable insights into the key safety considerations to keep in mind while using this equipment. By adhering to these guidelines, individuals can minimize risks, prevent accidents, and maintain a secure working environment.

Personal Protective Equipment (PPE)

Always wear the necessary Personal Protective Equipment (PPE) before operating a band saw. It is crucial to avoid loose clothing or jewelry that may get entangled in the machinery.

Equipment Inspection

Before starting, the band saw

- Verify that the blade is adequately tensioned, securely fastened, and free from any signs of damage or excessive wear.

- Check that all safety guards are correctly installed and functioning effectively. If any issues are detected, promptly report them to a supervisor or maintenance personnel for immediate resolution.

Organized Workspace

Maintaining a clean and organized workspace around the band saw is vital. Remove any potential hazards, such as debris, tools, or obstructions, that may impede safe operation. Adequate lighting should be ensured to enhance visibility and minimize the likelihood of accidents.

Material Preparation

Before cutting operations, ensure the processed material is securely fastened and adequately supported. Utilize clamps or appropriate fixtures to prevent movement during the cutting process. This precautionary measure reduces the risk of material binding or kicking back, which can lead to injuries.

Cutting Technique

When using a band saw, employ a firm grip on the material while applying a steady and controlled feed rate. Avoid exerting excessive force or feeding the material too quickly, which may cause the blade to deflect or break. Furthermore, refrain from cutting small or irregularly shaped materials that cannot be securely fastened.

Emergency Stop and First Aid

Familiarize yourself with the location and operation of the band saw’s emergency stop button. Immediately press the emergency stop button to halt the machine in an emergency or unsafe situation.

Additionally, ensure that a well-equipped first aid kit is readily available in close proximity to the band saw, enabling swift response in case of injuries.

Maintenance and Caring for a Band Saw

The band saw is a versatile and widely used power tool in various industries, including woodworking and metalworking. This article presents essential guidelines for maintaining and caring for a band saw, promoting optimal performance and longevity.

Regular Cleaning

Maintaining cleanliness is vital for the proper functioning of your band saw. Before cleaning, disconnect the power supply to ensure safety.

Employ a soft brush or compressed air to remove dust, debris, and residue from the exterior components, such as the blade, table, guides, and wheels. Conducting a thorough but gentle cleaning process is crucial to prevent any potential damage.

Blade Inspection and Tensioning

Before each use, inspect the band saw blade carefully. Look for signs of damage, including cracks, dullness, or missing teeth. If any issues are detected, promptly replace the blade to maintain optimal performance.

Additionally, assess the blade’s tension by applying light pressure with your finger. When plucked, the blade should produce a clear, ringing sound, indicating appropriate tension.

Lubrication

Proper lubrication is essential for your band saw’s smooth operation and longevity. Follow the manufacturer’s recommendations and apply a suitable lubricant to the blade, guides, and wheels. Be cautious not to over-lubricate, as excessive oil or grease may attract dust and debris, leading to potential clogs.

Adjustment of Guides and Tracking

Regularly inspect and adjust the blade guides to ensure proper alignment. Misaligned directions can result in uneven blade wear and inaccurate cuts. Adjust the tracking knob to center the blade on the wheels during operation, promoting optimal performance.

Blade Cleaning and Resawing

To remove pitch and resin buildup from the blade, periodic cleaning is necessary. Moreover, when resawing, consider applying a silicone-based lubricant on the blade to minimize friction and prevent excessive heat buildup.

Prioritize Safety Measures

Always prioritize safety when operating a band saw. Wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves. Ensure that the band saw is properly grounded to prevent electrical hazards.