Are you someone who enjoys woodworking projects or finds yourself frequently using a table saw? If so, you may have contemplated the advantages of having a table saw fence.

A table saw fence is an essential accessory that assists in achieving precise and accurate cuts, ultimately making your woodworking tasks safer and more efficient.

This guide will explore the step-by-step process of how to make a table saw fence? From scratch. This guide gives you the necessary knowledge and confidence to undertake this DIY project.

Materials

First and foremost, you require a sturdy and flat piece of plywood or hardwood that will serve as the main body of the fence. Choosing a material that is at least 3/4 inch thick is advisable for durability. Plywood is a cost-effective option, while hardwood offers increased strength and longevity.

Additionally, you will need an aluminium extrusion that acts as the guide rail for the fence, ensuring smooth and precise movement. Look for a compatible T-track or similar extrusion with a flat bottom and pre-drilled holes for easy attachment to the fence.

Accuracy is crucial in construction, so having a measuring tape or ruler on hand is essential. These tools will help you align the fence correctly and achieve consistent cuts. Additionally, screws and bolts are necessary to securely fasten the fence components.

It is important to select appropriate screws and bolts suitable for the thickness of your chosen plywood or hardwood. Make sure they are long enough to provide a strong connection.

Create holes for the screws and bolts

To create holes for the screws and bolts, a drill with the corresponding drill bits is indispensable. Be sure to choose drill bits that match the size of your fasteners.

Depending on the design of your fence, you may also need a saw or router. A circular or table saw can be useful for cutting straight edges, while a router can help create intricate shapes or channels.

Use sandpaper or a sanding block to achieve a smooth and polished finish. These tools will help eliminate rough edges, splinters, or imperfections on the wood surfaces.

Lastly, prioritize safety by wearing protective goggles, ear protection, and gloves when operating power tools. Ensure your workspace is well-ventilated, and take necessary precautions to prevent accidents.

Gathering these materials and following the necessary steps will give you everything you need to construct your table saw fence.

Remember to measure accurately, adhere to safety guidelines, and work diligently to create a fence that enhances the functionality and precision of your table saw.

Tools

To begin, you’ll need a tape measure or ruler for accurate measurements, ensuring precise cuts and placements. A circular saw or table saw is essential for cutting the main body of the fence from the plywood or hardwood material, providing clean and straight cuts.

Additionally, a drill with the appropriate drill bits is necessary for creating holes for screws and bolts during the assembly process.

You’ll also need a screwdriver and wrench to securely tighten the screws and bolts, selecting the proper screwdriver type (flathead or Phillips) and ensuring the wrench fits the bolt size.

Depending on your fence design, a router can be useful for shaping intricate details, such as channels or dadoes on the fence components, adding customization and functionality.

Clamps are invaluable for securely holding the fence components together while you drill or attach them, ensuring alignment and stability throughout the assembly process.

After cutting and drilling, sandpaper or a sanding block is necessary for smoothing any rough edges or surfaces, providing a polished finish and minimizing the risk of splinters.

Lastly, prioritize safety by wearing protective goggles, ear protection, and gloves when using power tools. Consider using a dust mask or respirator to protect yourself from fine wood particles or dust.

With these essential tools at your disposal, you’ll be well-equipped to successfully construct your table saw fence. Remember to take accurate measurements, follow safety guidelines, and work carefully to create a functional and reliable fence for your table saw.

Step-by-Step Process

Step 1: Fabricating the Aluminum Rail

To begin making a table saw fence, the first step is fabricating the aluminium rail. The aluminium rail serves as a guide for the fence to slide along smoothly. Follow these detailed instructions to fabricate the rail:

Measuring and Marking the Length

Start by measuring the desired length for your table saw fence. Mark the measurements on the aluminium rail using a marker or a scribe.

Securing the Aluminum Rail

Place the aluminium rail securely on a workbench or a sturdy surface.

Cutting the Aluminum Rail

Use a hacksaw or a mitre saw with a metal-cutting blade to carefully cut the aluminium rail along the marked line. Take your time and make slow, controlled cuts to ensure accuracy.

Smoothing the Edges

You may notice rough edges or burrs after cutting the rail. Use a file or sandpaper to gently remove any sharp or uneven edges to create smooth and clean edges. This step is important to ensure the fence slides smoothly along the rail without obstructions.

Checking for Straightness

Place a straightedge or a level along the length of the aluminium rail to check for any bends or deformations. If you notice any irregularities, carefully bend or straighten the rail using clamps or a vice until it is perfectly straight. Having a straight rail is crucial for the fence to glide accurately along its length.

Drilling Mounting Holes

Determine the appropriate locations for the mounting holes along the rail. These holes will allow you to securely attach the rail to the table saw. Mark the hole positions using a centre punch or a nail to create a starting point.

Then, carefully drill the holes at the marked positions using an appropriate drill bit. Ensure the holes are properly aligned along the length of the rail for even and stable attachment.

Step 2: Installing the Rail

After fabricating the aluminium rail for your table saw fence, it’s time to move on to the installation process. Follow these detailed instructions to ensure a successful installation:

Positioning the Rail

Determine the appropriate placement for the rail on your table saw. Refer to the user manual of your table saw for specific guidelines on rail placement, if available.

Marking the Mounting Hole Locations

With the rail in the desired position, use a pencil or marker to clearly mark the locations of the mounting holes on the table saw surface. Make sure the marks accurately represent the hole positions on the rail.

Preparing the Mounting Holes

Using an appropriate-sized drill bit, create pilot holes at the marked locations on the table saw.

Aligning and Securing the Rail

Carefully position the rail over the pilot holes on the table saw, ensuring it aligns properly with the holes. Then, using screws or bolts suitable for the material of your table saw, attach the rail securely to the table saw. Start by driving one screw or bolt at a time, ensuring alignment.

Verifying Alignment

Once the rail is installed, double-check its alignment. Ensure it remains parallel to the saw blade and correctly positioned for precise fence movement. Use a straightedge or a level to verify its alignment. If any adjustments are necessary, loosen the screws or bolts slightly, make the required corrections, and then tighten them securely again.

Testing and Fine-Tuning

Slide the fence along the rail to test its movement. It should glide smoothly without any obstructions or excessive friction. If you encounter any issues, carefully inspect the rail and the fence for any misalignments or interferences. Make minor adjustments as needed to achieve optimal performance.

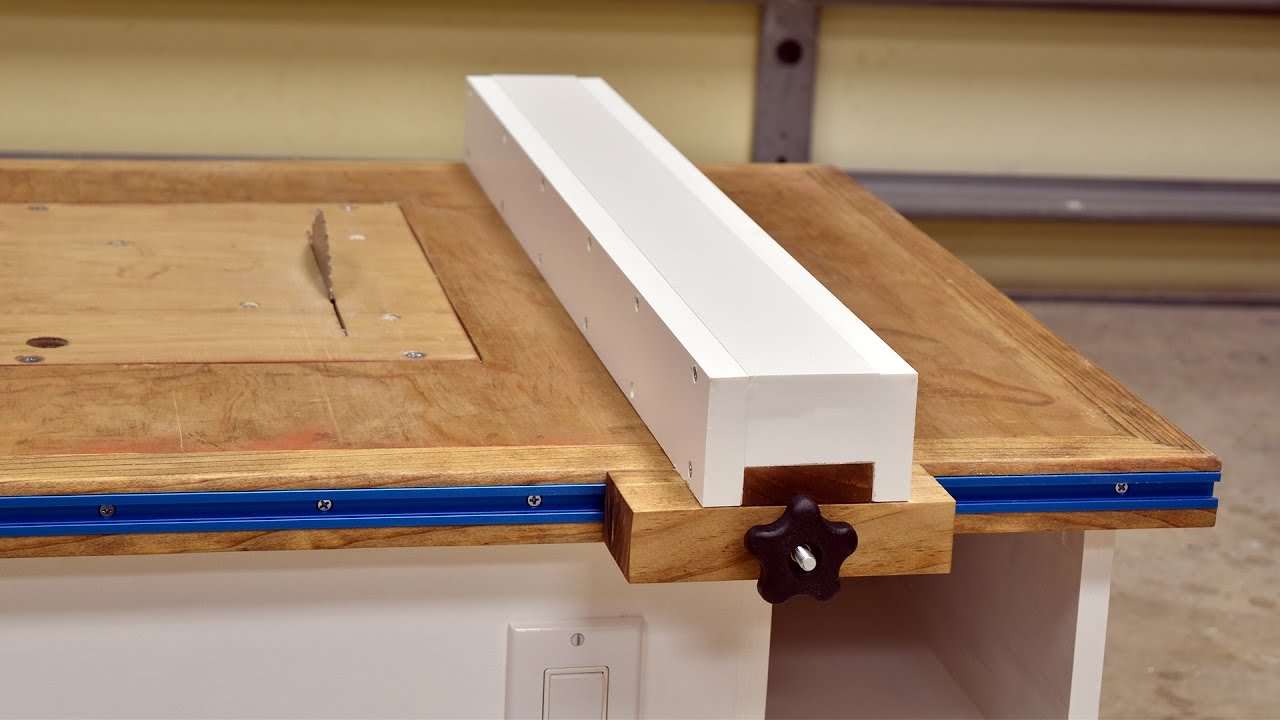

Step 3: Sliding Mechanism

After installing the rail for your table saw fence, the next step is to create a sliding mechanism that allows the fence to move smoothly along the rail. Follow these step-by-step instructions to build the sliding mechanism:

Gather the necessary materials

Collect the required materials for the sliding mechanism, including nylon or UHMW (Ultra-High Molecular Weight) plastic strips, T-track, knobs, and bolts. Ensure that the plastic strips and T-track are of appropriate sizes and lengths for your table saw fence.

Attach the plastic strips

- Cut the plastic strips to match the length of the fence.

- After Placing one strip on each side of the fence, align them parallel to the rail.

- Use screws or adhesive to securely attach the plastic strips to the fence.

These strips will provide a smooth, low-friction surface for the fence to slide along the rail.

Install the T-track

- Measure the distance between the plastic strips on the fence and cut the T-track accordingly.

- Position the T-track between the plastic strips, ensuring it is parallel to the rail.

- Securely attach the T-track to the fence using screws or bolts.

The T-track is a channel for attaching accessories or jigs to the fence, adding versatility to your table saw setup.

Test the sliding mechanism

- Slide the fence along the rail to test its movement.

- Ensure it glides smoothly along the plastic strips and the T-track without binding or resistance. If you encounter any issues, check for misalignments or obstructions.

- Make necessary adjustments or modifications to ensure smooth sliding.

Add knobs for locking

- Install knobs on the T-track to secure the fence in position.

- Choose knobs with threaded inserts that fit into the T-track slots.

- Insert the knobs into the T-track and tighten them to lock the fence in place.

This allows you to easily position and lock the fence from the saw blade at different distances.

Fine-tune the sliding mechanism

- Once the sliding mechanism is installed, check for any areas requiring fine-tuning.

- Ensure the fence slides smoothly and securely along the rail and locks firmly in position when needed.

- Make any necessary adjustments to achieve optimal performance.

By following these steps, you will successfully create a sliding mechanism for your table saw fence. The plastic strips, T-track, knobs, and bolts work together to facilitate smooth movement, precise positioning, and secure locking of the fence. This enhances the accuracy and functionality of your table saw setup, allowing you to work with efficiency and confidence.

Step 4: Assembling

In this step, we will focus on assembling the various components of the table saw fence. Follow these instructions to complete the assembly process:

Gather the components: Collect all the necessary components for the table saw fence assembly, including the main fence body, sliding mechanism, measuring scale, and any additional accessories or attachments you plan to include.

Attach the sliding mechanism: Align the sliding mechanism, which includes the plastic strips and T-track, with the pre-installed rail on the table saw. Ensure that the plastic strips rest on the rail and that the T-track is oriented properly for the desired movement of the fence. Securely attach the sliding mechanism to the fence body using screws, bolts, or other appropriate fasteners.

Install the measuring scale: If your table saw fence requires a measuring scale for accurate positioning, carefully install it according to the manufacturer’s instructions. This typically involves attaching the scale to the fence body using screws or adhesive. Ensure the scale is aligned properly with the sliding mechanism and provides accurate measurements along the length of the fence.

Add additional accessories: Depending on your specific needs, you may incorporate additional accessories or attachments, such as a hold-down clamp or a sacrificial face. Attach these accessories securely to the fence body using the provided mounting holes or brackets. Ensure they are aligned properly and do not obstruct the movement of the fence or interfere with other components.

Test the assembly:

- Slide the fence along the rail for movement and functionality.

- Verify that the sliding mechanism operates smoothly, the measuring scale provides accurate readings, and any added accessories function as intended.

- Make any necessary adjustments or tweaks to ensure optimal performance.

Finalize the assembly: Once you are satisfied with the fit and functionality of the table saw fence assembly, double-check all the fasteners and connections to ensure they are tight and secure.

By following these steps, you will successfully assemble your table saw fence. The sliding mechanism, measuring scale, and additional accessories will work together to provide accurate and convenient operation.

Step 5: Carriage Bolts

In this step, we will focus on using carriage bolts to securely fasten the table saw fence to the table saw. Follow these instructions to properly install the carriage bolts:

Determine the appropriate size: Select the correct size of carriage bolts for your table saw fence. Consider the thickness of the fence and the size of the pre-drilled holes on the table saw.

Align the fence: Position the table saw fence in the desired location on the table saw. Ensure it is parallel to the blade and properly aligned for precise cuts. Make any necessary adjustments to achieve proper alignment.

Mark the hole positions: Use a pencil or marker to mark the positions on the fence where the carriage bolts will be inserted. These marks should align with the pre-drilled holes on the table saw.

Drill pilot holes: The pilot holes will guide the carriage bolts and prevent the wood from splitting or getting damaged.

Insert the carriage bolts: Insert the carriage bolts into the pilot holes inside the fence, ensuring that the threaded ends protrude from the outside. Ensure the carriage bolt’s square shoulder fits securely into the countersunk portion of the hole to prevent rotation.

Secure with washers and nuts: Place a washer onto each protruding carriage bolt, followed by a nut.

Check alignment: Double-check the alignment of the fence and ensure that it remains parallel to the blade. If necessary, loosen the nuts, adjust the alignment of the fence, and then re-tighten the nuts.

Test the fence

- Slide the fence along the rail and test its movement.

- Verify that it glides smoothly and remains securely in position.

- If you encounter any issues, re-evaluate the alignment and make further adjustments.

Step 6: Fence

In this step, we will focus on constructing the fence itself. The fence plays a crucial role in guiding your workpieces during cutting. Follow these instructions to build the fence for your table saw:

Determine the dimensions: Measure the desired height and length of the fence based on your specific needs and the size of your table saw. Consider the maximum cutting capacity and the type of workpieces you will be handling.

Cut the material: Choose a sturdy and straight material for the fence, such as plywood, MDF (Medium Density Fiberboard), or hardwood. Use a saw or an appropriate cutting tool to cut the material to the determined height and length, ensuring clean and precise edges.

Smooth the edges: This step is important to prevent splinters and provide a comfortable grip when handling the fence.

Attach the sliding mechanism

- Position the sliding mechanism on the face of the fence, including the plastic strips and T-track.

- Ensure the plastic strips align with the rail and the T-track is oriented properly for smooth movement.

- Securely attach the sliding mechanism to the fence using screws or bolts, following the manufacturer’s instructions.

Install measuring and marking aids: Depending on your preferences and needs, you may incorporate measuring and marking aids on the face of the fence. This can include adhesive measuring tapes or a measuring scale, allowing for precise and repeatable positioning of the workpiece.

Apply a protective finish: To protect the fence and enhance its durability, consider a protective finish. This can be a clear coat of varnish, paint, or a suitable wood finish. Follow the manufacturer’s instructions for the chosen finish and ensure it is fully dry before using the fence.

Attach the fence to the sliding mechanism

- Align the holes on the sliding mechanism with the corresponding holes on the fence.

- Insert screws or bolts through the holes and securely tighten them to attach the fence to the sliding mechanism.

- Double-check the alignment and make any necessary adjustments to ensure the fence is properly positioned parallel to the blade.

Test the fence

- Slide it along the rail, verify it moves smoothly, and lock it securely.

- Ensure that the measuring and marking aids provide accurate readings.

- Make any final adjustments or refinements to achieve optimal performance.

By following these steps, you will successfully construct the fence for your table saw. The fence will provide stability, precise guidance, and measurement references, enabling you to make accurate cuts and achieve excellent woodworking results.

Step 7: Testing

Follow these instructions to ensure that the fence performs as expected:

Secure the fence in position: Use the locking knobs or mechanisms on the sliding mechanism to securely lock the fence along the rail. Make sure it is tightly secured and does not move during testing.

Align the fence parallel to the blade

- Use a straightedge or square to verify the fence is parallel to the saw blade.

- Place the straightedge against the blade and slide it along the length of the fence.

- Ensure no gaps or deviations between the straightedge and the fence along its length.

Test the fence for squareness: Position a square against the fence, with one edge touching the face of the fence and the other edge extending towards the blade. Slide the square along the length of the fence and ensure that it remains in contact with the fence without any gaps or misalignment.

Make test cuts

- Make some test cuts using scrap material with the fence securely locked in position and properly aligned.

- Pay attention to the accuracy and consistency of the cuts.

- Ensure that the workpiece remains firmly against the fence throughout the cutting process.

Check the measurements: Measure the resulting cuts using a measuring tape or precision instrument. Verify if the measurements match your desired dimensions and the cuts are square and accurate.

Assess the overall performance: Evaluate the overall performance of the table saw fence based on its stability, ease of use, accuracy, and quality of the cuts produced. Take note of any issues or areas requiring further adjustment or improvement.

Make necessary adjustments: If you identify any issues or discrepancies during testing, make the necessary adjustments to the fence. This can include realigning the fence, fine-tuning the locking mechanism, or modifying other components.

Retest and refine: After making adjustments, repeat the testing process to ensure the fence functions optimally. Continue to refine and make any additional adjustments until you are satisfied with the performance and accuracy of the table saw fence.

Testing is crucial to ensure that the fence performs as intended and provides you with precise and reliable cuts for your woodworking projects.